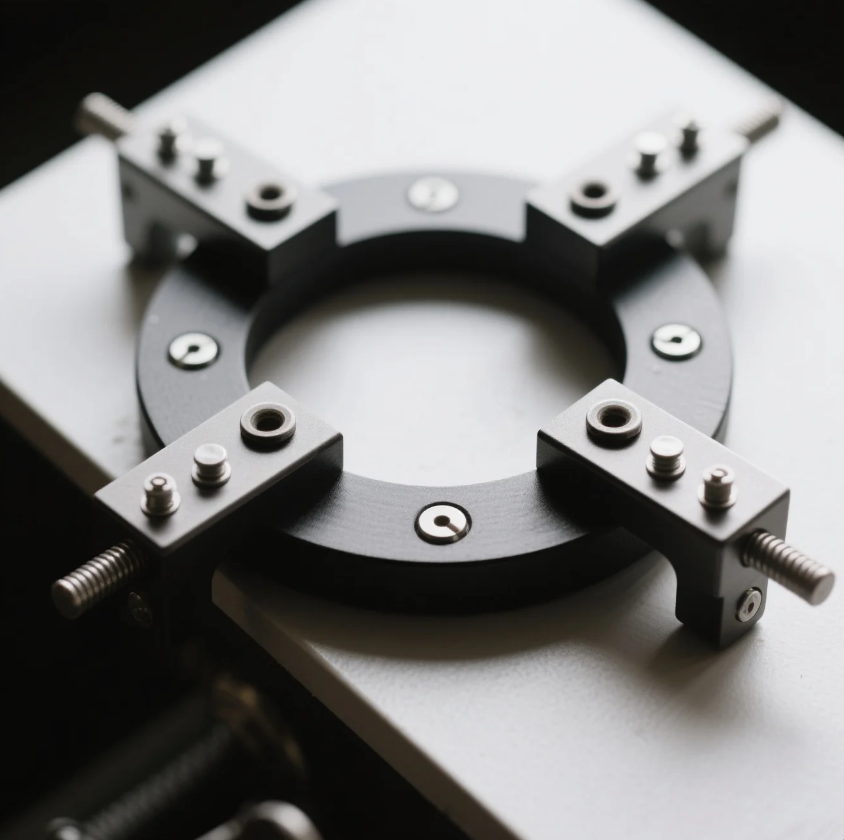

What Are Circle Clamps Called?

Many buyers describe “circle clamps” in RFQs—yet this informal term can refer to several different products.

Circle clamps are typically known as hose clamps, ring clamps, or band clamps, used to secure hoses onto fittings or pipes.

At Prime, we help B2B clients identify and source the exact clamp they need by matching design, force, and application. Let’s clear up the confusion around circular clamp types.

What Are the Three Types of Hose Clamps?

Hose clamps are common but often misunderstood. Different industries use different types based on pressure, vibration, and fluid.

The three main types of hose clamps are: worm gear clamps, spring clamps, and T-bolt clamps.

Each offers different holding strength, temperature tolerance, and adjustability.

Hose Clamp Types Overview

| Clamp Type | Adjustability | Application |

|---|---|---|

| Worm gear clamp | Screw-tightened | Automotive, home plumbing |

| Spring clamp | Tension-based | Fuel lines, low-pressure hoses |

| T-bolt clamp | High-torque bolt | Turbo, coolant, industrial hoses |

At Prime, we supply all three clamp types in stainless steel, zinc-plated steel, and custom widths, meeting DIN 3017 and SAE J1508 standards.

What Is the Difference Between a Bar Clamp and a C Clamp?

Bar clamps and C-clamps are both used in workshops—but their designs and applications differ significantly.

A bar clamp has a long sliding rail for wide spans. A C-clamp has a fixed throat for compact pressure holding.

C Clamp vs. Bar Clamp Comparison

| Feature | C Clamp | Bar Clamp |

|---|---|---|

| Design | Fixed-frame (C-shape) | Sliding arm on long bar |

| Reach | Limited | Adjustable, long span |

| Force | High, localized | Moderate, broad surface |

| Application | Metalworking, tight spots | Woodworking, frame gluing |

We manufacture C-clamps for welding setups and bar clamps for furniture assembly, available with cast steel or drop-forged bodies.

What Is the Difference Between a Band Clamp and a Hose Clamp?

Many clients think band clamps and hose clamps are identical—but they serve slightly different roles.

A band clamp typically wraps around larger surfaces and applies uniform pressure. A hose clamp focuses on sealing around cylindrical hose joints.

Band Clamp vs. Hose Clamp

| Feature | Band Clamp | Hose Clamp |

|---|---|---|

| Width | Wider bands | Narrower |

| Closure style | Ratchet, tension, or buckle | Screw or spring |

| Best use | Holding ducts, barrels | Securing hoses to nozzles |

We offer custom stainless steel band clamps with locking latch systems for packaging, HVAC, and pipe sealing—shipped globally in bulk quantities.

What Is the Difference Between a Spring Clamp and a Worm Clamp?

These two are both classified as “hose clamps,” but their design and working method are very different.

A spring clamp relies on pre-tension to grip. A worm clamp uses a screw to adjust pressure.

Spring clamps are faster to install but harder to adjust. Worm clamps are more precise and reusable.

Spring Clamp vs. Worm Clamp

| Feature | Spring Clamp | Worm Clamp |

|---|---|---|

| Mechanism | One-piece tension ring | Screw-tightened band |

| Adjustment | Fixed size | Fully adjustable |

| Use case | Factory hose lines | Repair, maintenance, general use |

We’ve helped clients in the automotive and HVAC sectors switch from spring clamps to worm gear clamps for easier field maintenance—reducing service time and tool requirements.

Conclusion

Circle clamps are better known as hose clamps—most commonly worm gear, spring, or T-bolt types. Choose based on pressure, diameter, and reusability.

Need durable hose or band clamps for industrial or automotive use?

At Prime, we manufacture precision-engineered clamps in a variety of widths, torque ratings, and coatings.

🔩 Worm, spring, T-bolt, band, and custom circular clamps

📦 Stainless, plated, or coated finishes available

🛠 Fully tested to meet global standards (DIN, SAE, ISO)

📩 Send your spec now for a fast quote and expert clamp selection support!