Why are injection molding machines so expensive?

Buyers are often shocked by the high cost of injection molding machines and unsure if they’re worth the investment.

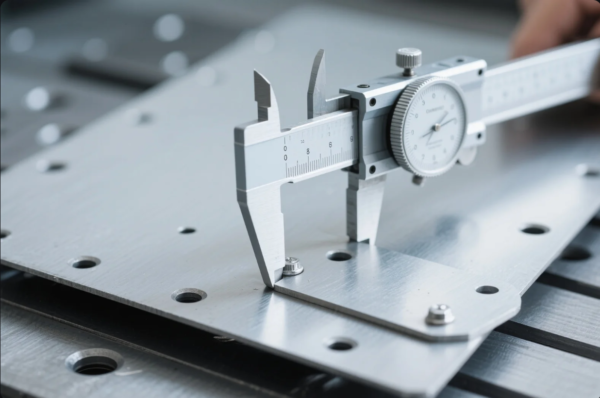

Injection molding machines are expensive due to precision engineering, high-pressure systems, and automation needs.

At Prime, we help clients reduce cost by offering custom plastic parts production without the burden of owning complex equipment.

How expensive are injection molding machines?

Prices vary widely by size, but even basic machines can cost more than a car.

Injection molding machines range from \$5,000 to \$250,000+, depending on size, tonnage, and automation.

One of our U.S. buyers considered buying a machine for low-volume production. After consulting Prime, they chose to outsource instead — saving over \$50,000.

Injection Molding Machine Price Breakdown

| Machine Type | Tonnage | Estimated Price |

|---|---|---|

| Small (10–50 ton) | \$5,000–\$15,000 | Prototypes, micro parts |

| Medium (100–300 ton) | \$30,000–\$80,000 | General parts production |

| Large (500+ ton) | \$100,000+ | Automotive, industrial |

Owning a machine also requires trained staff, mold setup tools, and maintenance — costs that add up fast.

What is the disadvantage of injection molding machine?

Owning a machine seems convenient but comes with hidden risks.

High initial investment, mold cost, long setup time, and limited flexibility are key disadvantages.

At Prime, we’ve helped several clients reduce risk by outsourcing instead of buying. This allows them to launch products faster without committing capital upfront.

Downsides of Injection Molding Machines

| Disadvantage | Description |

|---|---|

| High capital cost | Machines and molds cost \$50k+ |

| Limited part flexibility | Changing molds is time-consuming |

| High maintenance need | Requires skilled technicians |

| Space requirements | Machines take up factory floor space |

If your volume is low or part design changes often, owning may not be the right move. Prime offers flexible production for changing needs.

What is a cheaper alternative to injection moulding?

Startups often can’t afford injection molding molds or machines early on.

Cheaper alternatives include 3D printing, vacuum casting, and urethane molding for low-volume runs.

We’ve worked with small batch customers who started with 3D printing but later moved to Prime for scalable custom plastic parts once demand increased.

Injection Molding Alternatives

| Method | Best For | Cost Level |

|---|---|---|

| 3D printing | Prototypes, short runs | Low |

| Urethane casting | 50–1000 pcs | Medium |

| Thermoforming | Thin-wall large parts | Low–Medium |

| CNC machining | Low-run rigid parts | Medium–High |

Outsourcing to an ISO-certified plastic parts supplier like Prime combines quality and affordability — even better than many in-house methods.

What is the price of 15 ton injection molding machine?

Very small machines are used for prototypes or lab samples and have limited applications.

A 15-ton injection molding machine costs between \$4,000 and \$10,000, depending on build quality.

We supported an R\&D team in Europe that purchased a 15-ton machine for material testing. When ready for full production, they partnered with Prime to scale with no added machine investment.

15-Ton Machine Use Case

| Feature | Specification |

|---|---|

| Clamp force | 15 tons |

| Part size limit | < 30g |

| Ideal use | Prototypes, micro parts |

| Price | \$4,000 – \$10,000 |

While low-cost, these machines can’t support mass production or larger molds. That’s where Prime’s 10 production lines fill the gap.

Conclusion

Injection molding machines are costly due to precision, durability, and automation — but outsourcing saves capital.

Looking for a cost-effective way to produce custom plastic parts without spending \$50,000+? Contact Prime today. We offer ISO-certified manufacturing, global delivery, and flexible production. Use our website form for a free quote, mold cost estimate, or part consultation — and start scaling without the machinery burden.