Is injection molding cheaper than machining?

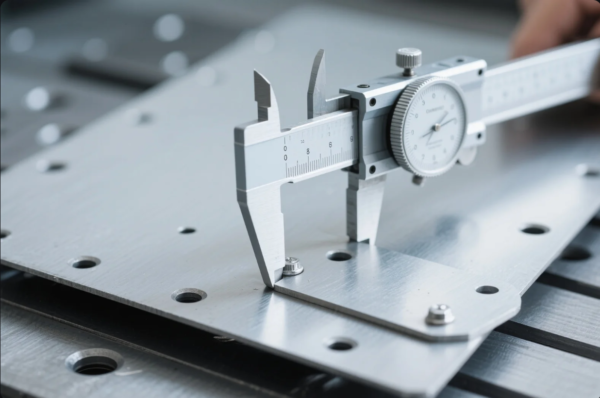

Buyers often compare injection molding and machining for cost, especially when scaling production.

Injection molding is cheaper than machining at high volumes. Machining is more cost-effective for low runs and prototyping.

At Prime, we help clients choose the most cost-efficient process for every stage — from small CNC batches to full-scale custom plastic parts molding.

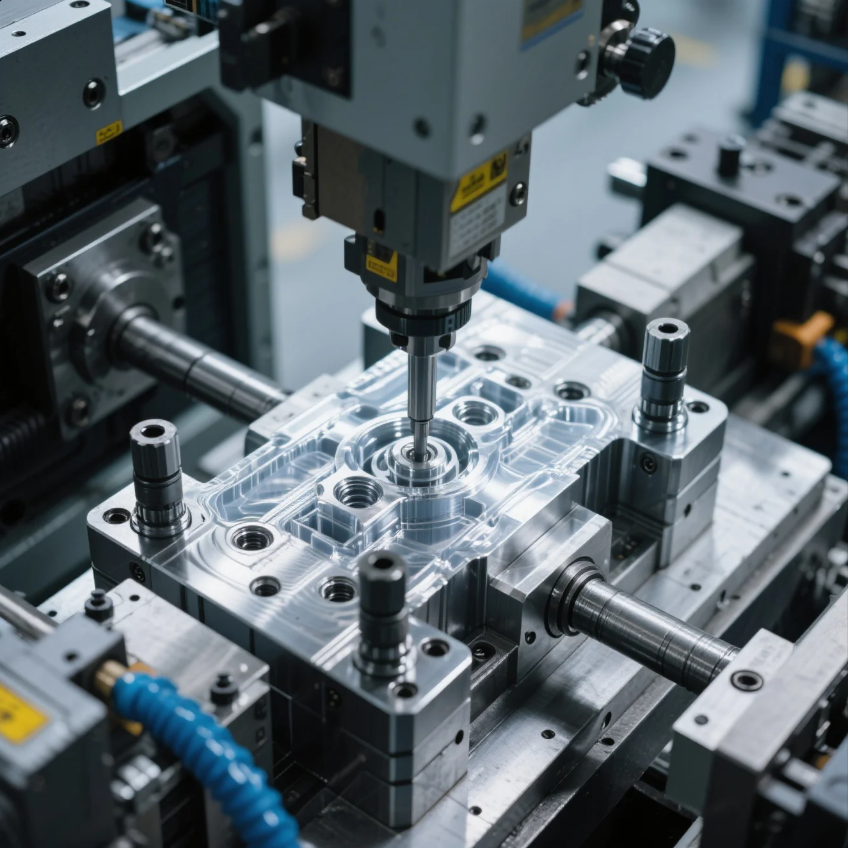

Is injection molding cheaper than CNC?

CNC machining offers precision, but high per-part cost limits its use in mass production.

Injection molding is significantly cheaper than CNC when producing thousands of parts.

One U.S. client switched from CNC to molded enclosures after we showed the savings: over 70% reduction in cost per part once the tooling paid off.

Injection Molding vs CNC Machining

| Factor | Injection Molding | CNC Machining |

|---|---|---|

| Upfront cost | High (mold needed) | Low (no tooling) |

| Per-part cost | Very low at scale | High per unit |

| Setup time | Longer | Fast setup |

| Design flexibility | Limited after mold made | Easy to revise |

Prime supports both methods. We help clients start with CNC for validation, then shift to molding for volume production.

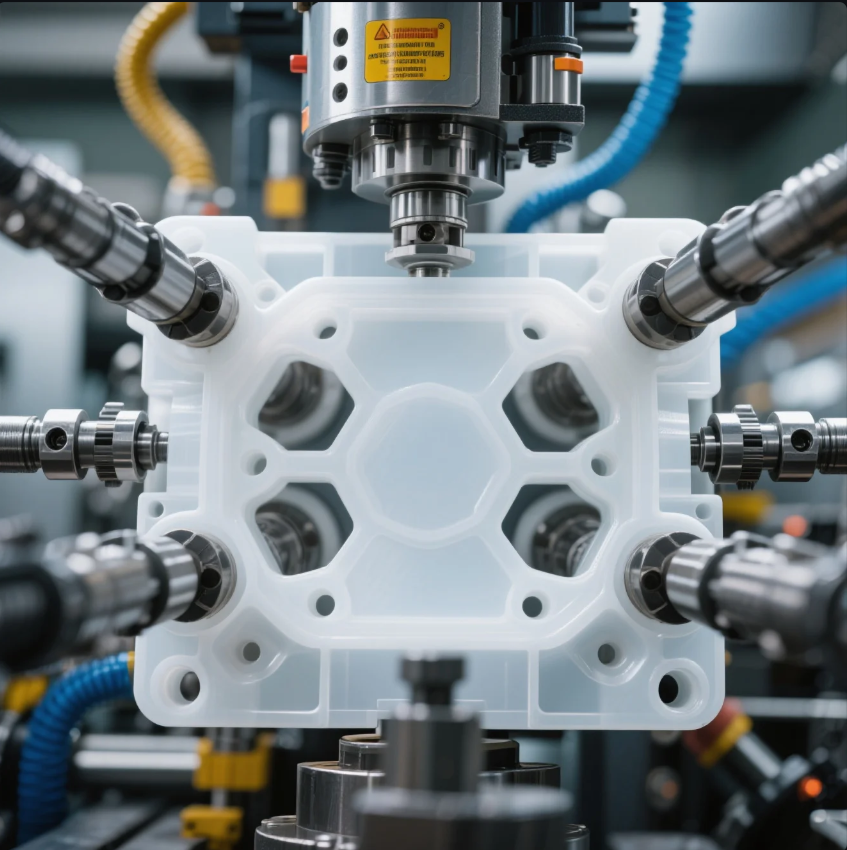

Is injection molding cheap?

Some buyers assume molding is always cheap — but that depends on quantity and part complexity.

Injection molding is only cost-effective when producing medium to high volumes.

We worked with an Australian startup that needed 20,000 parts annually. We quoted mold tooling at \$8,000 — but with a \$0.40 per-part cost. They broke even within two months compared to CNC.

Injection Molding Cost Factors

| Cost Type | Range | Notes |

|---|---|---|

| Mold tooling | \$3,000 – \$100,000 | One-time, upfront |

| Per-part cost | \$0.10 – \$5.00 | Lower with more volume |

| Setup cost | \$500 – \$2,000 | Charged per batch run |

Prime offers flexible tooling options, including aluminum molds and family molds to reduce initial costs.

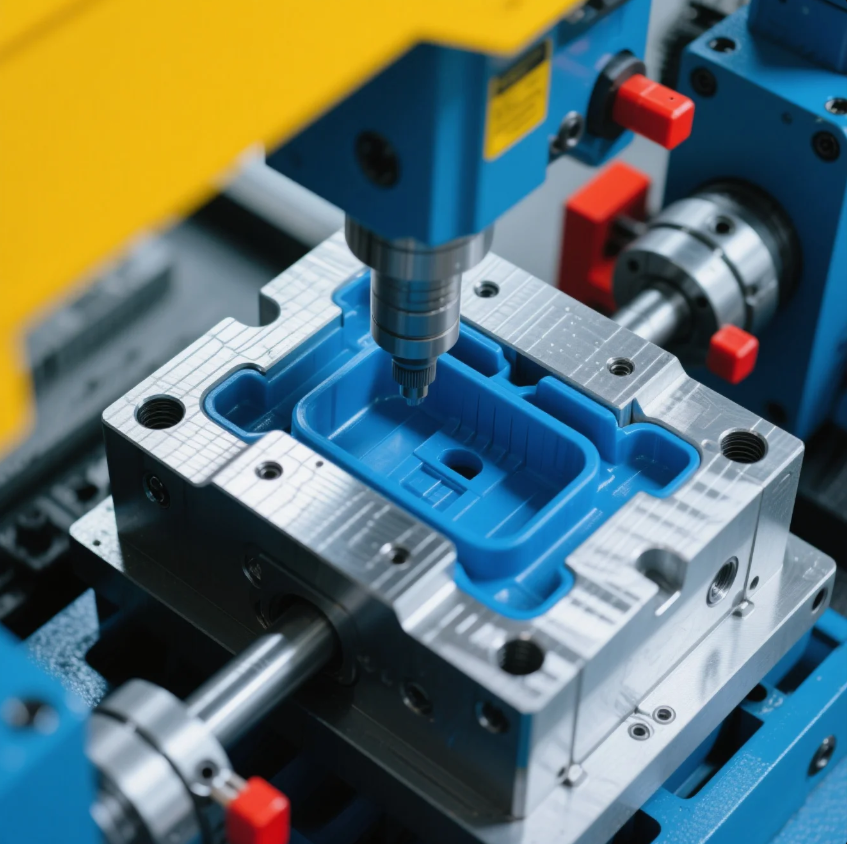

Is injection molding cheaper than 3D printing?

3D printing is fast for prototypes but too slow and costly for mass production.

Injection molding is far cheaper than 3D printing once volumes exceed 500–1000 parts.

One European electronics customer printed 300 units a month before switching to Prime. With injection molding, they cut cost per unit from \$9 to \$1.30.

Comparison: Molding vs 3D Printing

| Metric | Injection Molding | 3D Printing |

|---|---|---|

| Speed (per part) | Seconds | Minutes to hours |

| Surface finish | Smooth, ready to use | Layered, may need post-finish |

| Material cost | Lower per part | Higher per gram |

| Best use | 1,000+ parts | Prototypes, 1–100 parts |

For functional, end-use parts, custom molded plastic parts from Prime offer unbeatable value at volume.

What is the cost of 160 ton injection molding machine?

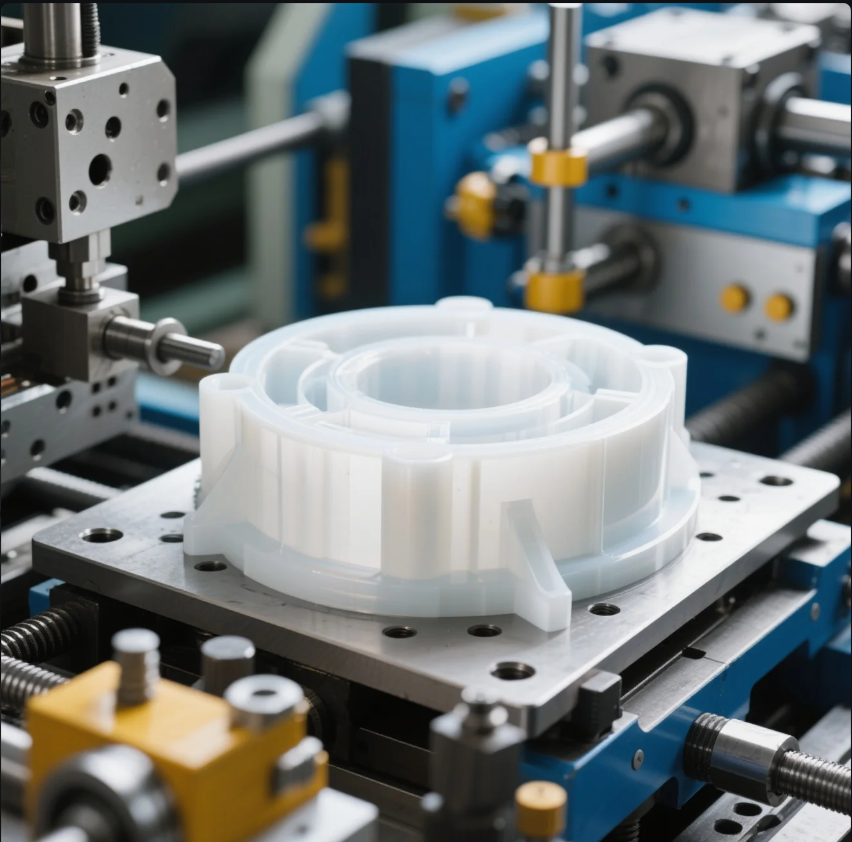

160-ton machines are ideal for medium-size molded components across automotive, electronics, and consumer products.

A 160-ton injection molding machine costs between \$25,000 and \$55,000 depending on features and origin.

One of our Middle East clients quoted a machine for \$48,000. After reviewing their ROI and demand forecasts, they outsourced to Prime — saving on labor, maintenance, and power.

160-Ton Machine Overview

| Feature | Specification |

|---|---|

| Clamp Force | 160 tons |

| Shot Size | 250–400g |

| Typical Parts | Enclosures, housings, brackets |

| Price Range | \$25,000 – \$55,000 |

If you're unsure about buying, Prime offers full-service molding with ISO-certified quality and global delivery.

Conclusion

Injection molding is cheaper than machining and 3D printing — but only at volume and with proper mold planning.

Need help choosing between CNC, 3D printing, or injection molding? Contact Prime for expert guidance. We offer custom plastic parts, low MOQ solutions, and fast tooling options. Use our website to request a free quote, cost comparison, or design consultation — and find the best fit for your production goals.