Is injection molding a good career?

Many job seekers and students ask whether injection molding offers long-term career potential and good pay.

Yes, injection molding is a strong career path with opportunities in production, engineering, quality control, and automation.

At Prime, we’ve worked with technicians, engineers, and plant managers who’ve built stable, well-paid careers in the custom plastic parts industry.

Is injection molding a hard job?

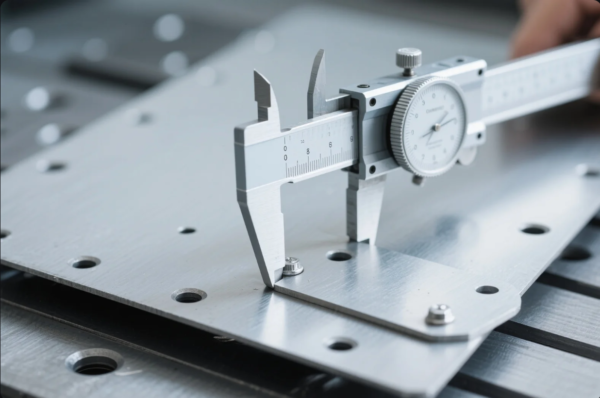

People often think running a molding machine is simple — but the job demands technical skill and attention to detail.

Injection molding requires focus, troubleshooting skills, and mechanical knowledge — especially for setup and quality roles.

At Prime, our operators go through hands-on training to learn proper cycle setup, temperature control, and mold handling. This ensures consistent output and ISO-certified part quality.

Job Complexity by Role

| Job Role | Difficulty Level |

|---|---|

| Machine Operator | Moderate – routine-based |

| Setup Technician | High – cycle & mold tuning |

| Mold Designer | Very high – CAD/CAM skills |

| Quality Inspector | Moderate – inspection & data |

Injection molding is not easy — but it’s rewarding, especially for those who like working with machines and solving production issues.

What is the future of injection molding?

The field is changing fast with smarter systems, sustainable materials, and automation.

Injection molding has a strong future, driven by demand for lightweight parts, global manufacturing, and sustainability.

At Prime, we’ve invested in servo-electric machines and material recycling systems. We also train our team on new polymers and automation software.

Key Industry Trends

| Trend | Career Impact |

|---|---|

| Automation | Need for robot programming |

| Digital monitoring | Demand for tech-savvy workers |

| Green materials | Growth in bio-based plastics |

| Customization | Strong demand for engineers |

Molding is becoming more technical, and companies like Prime need skilled people who can grow with these changes.

What is the hourly rate for injection molding?

Wages vary depending on the country, skill level, and job title.

In the U.S., hourly wages for injection molding range from \$15 to \$35+, depending on role and experience.

We’ve worked with global clients who also face labor cost challenges. Prime helps them balance labor rates by offering cost-efficient molded parts through automation and high efficiency.

U.S. Hourly Wage Estimates

| Job Title | Hourly Rate (USD) |

|---|---|

| Machine Operator | \$15 – \$20/hour |

| Mold Setter/Tech | \$20 – \$30/hour |

| Process Engineer | \$30 – \$40+/hour |

| Quality Inspector | \$18 – \$25/hour |

The more technical the role, the higher the earning potential — especially with certifications and training.

Is injection molding profitable?

Business owners and job seekers both ask whether the industry is still worth entering.

Yes, injection molding is highly profitable, especially when optimized for volume, quality, and efficiency.

One of our North American partners maintains 35% gross margins by using Prime as a custom plastic parts supplier, avoiding machine downtime and labor overhead.

Profit Drivers in Molding

| Factor | Profit Impact |

|---|---|

| Cycle optimization | Faster output, lower cost |

| Material selection | Better price-performance ratio |

| Defect control | Reduces waste and rework |

| Labor efficiency | Fewer hours per part |

Whether you’re on the factory floor or managing production, profitability depends on your ability to control these elements — a skillset Prime values and supports.

Conclusion

Injection molding offers a stable, well-paying career with room to grow in automation, engineering, and operations.

Interested in joining the molding industry or improving your current production setup? Reach out to Prime for a career consultation, plant support, or part cost analysis. With over 20 years of experience and ISO-certified facilities, we help people and businesses grow together.