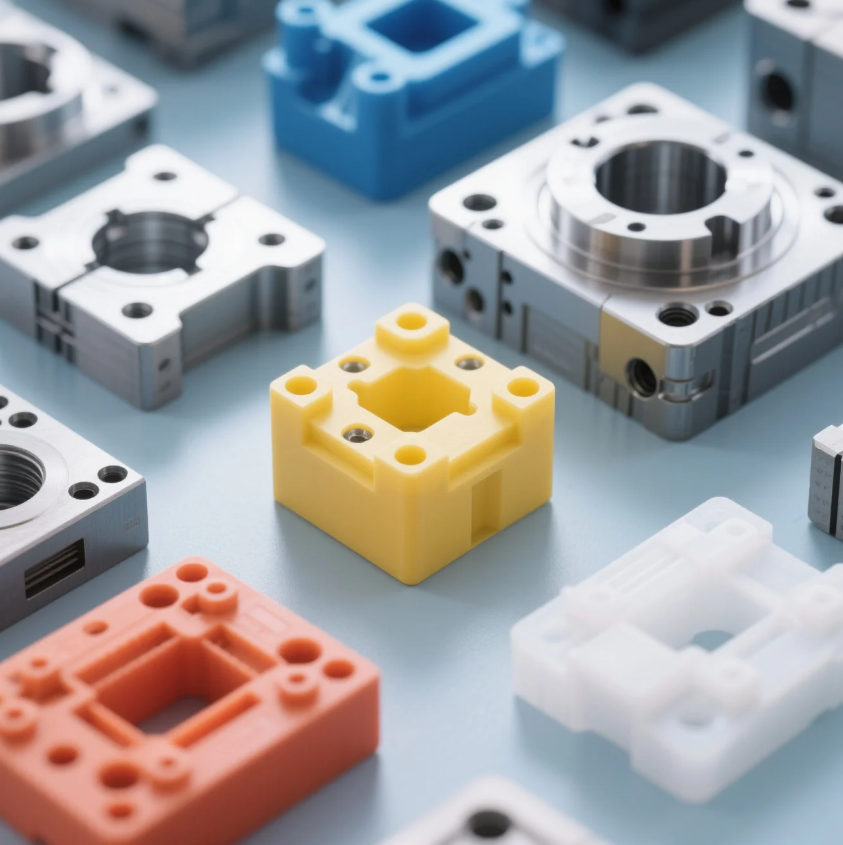

What is the easiest material to injection mold?

Many buyers want fast production with minimal issues — starting with materials that mold easily is key.

Polypropylene (PP), polyethylene (PE), and polystyrene (PS) are the easiest plastics to injection mold due to their flowability and thermal stability.

At Prime, we help clients choose the right resin for smooth cycles, fewer defects, and reliable custom plastic part production.

What is the easiest plastic to injection mold?

Not all plastics flow well or cool evenly — beginners often run into warping or short shots.

Polypropylene (PP) is widely considered the easiest plastic to injection mold thanks to its low melting point, stability, and low shrinkage.

A North American client switched from ABS to PP for a cosmetic housing and instantly saw improved cycle time and reduced part warping.

Easy-to-Mold Plastics

| Plastic | Ease of Molding | Common Use Case |

|---|---|---|

| Polypropylene (PP) | Very high | Packaging, caps, containers |

| Polyethylene (PE) | High | Bottles, toys, tubing |

| Polystyrene (PS) | Moderate | Housings, electronics shells |

At Prime, we recommend PP for low-risk, high-output projects — especially for first-time molders or budget-conscious buyers.

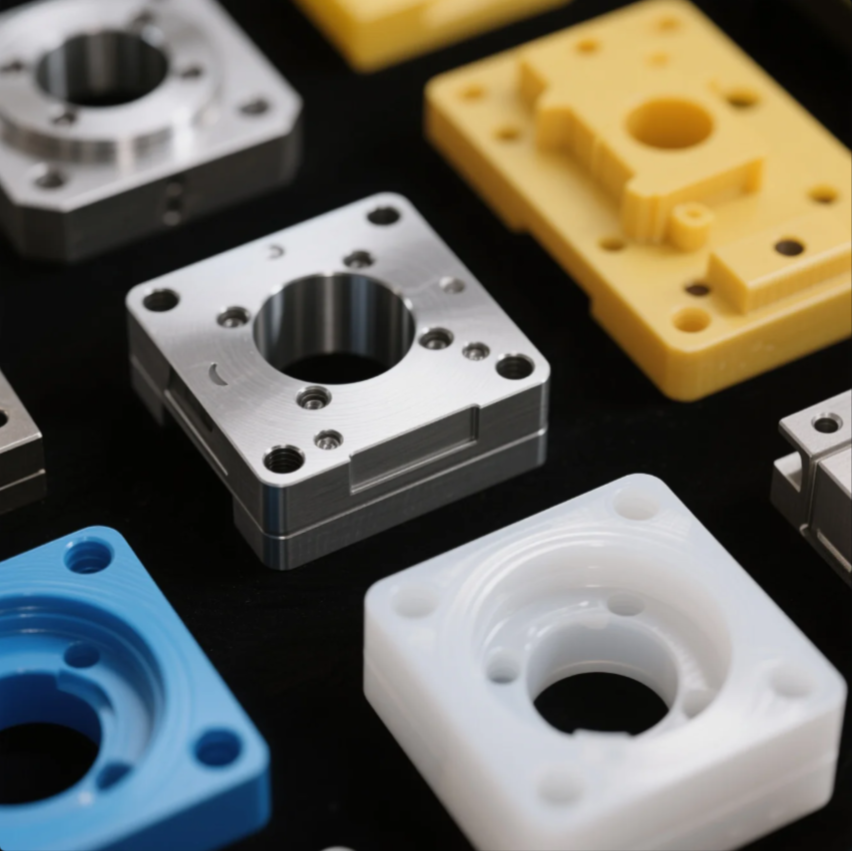

How much does a simple injection mold cost?

Mold cost can be intimidating, but simple molds don’t have to break the bank.

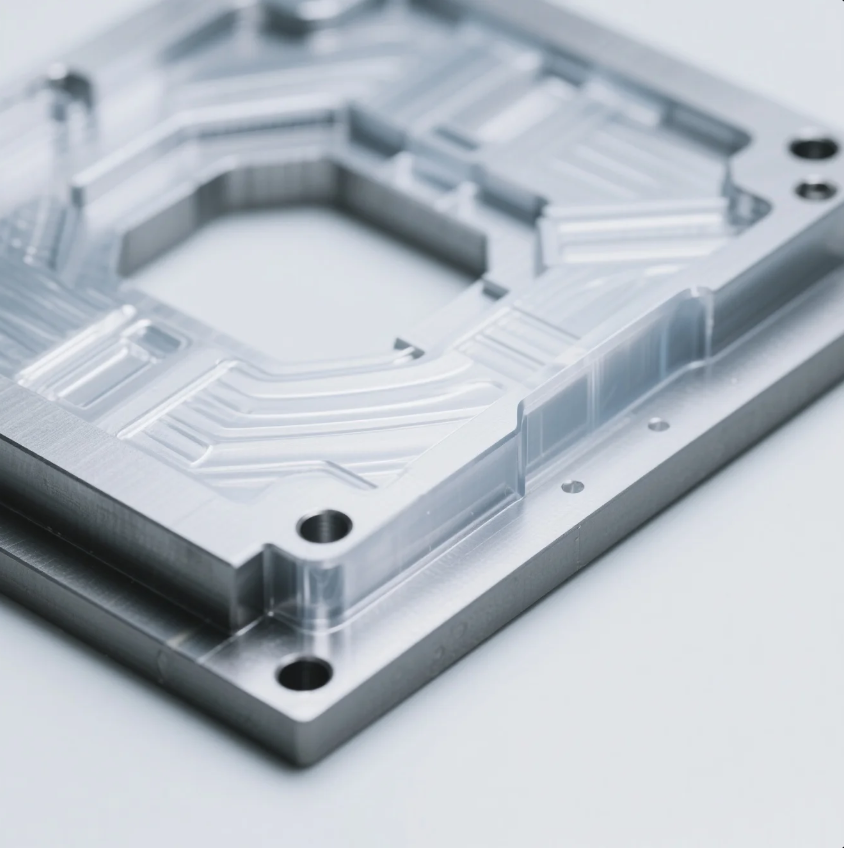

A simple single-cavity injection mold can cost between \$3,000 and \$8,000, depending on material and finish.

One of our European clients needed a basic enclosure mold. With aluminum tooling and a clean parting line, we delivered it for \$4,200 — ready in just 15 days.

Cost of a Basic Injection Mold

| Feature | Typical Value |

|---|---|

| Cavity count | Single |

| Mold material | Aluminum or P20 steel |

| Lead time | 2–4 weeks |

| Cost range | \$3,000 – \$8,000 |

Prime also offers family molds and modular inserts to lower costs while boosting flexibility.

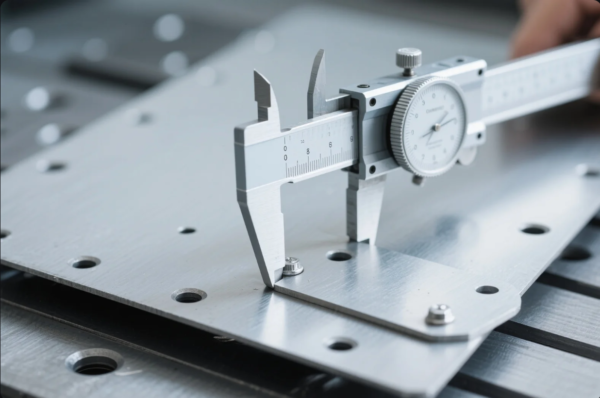

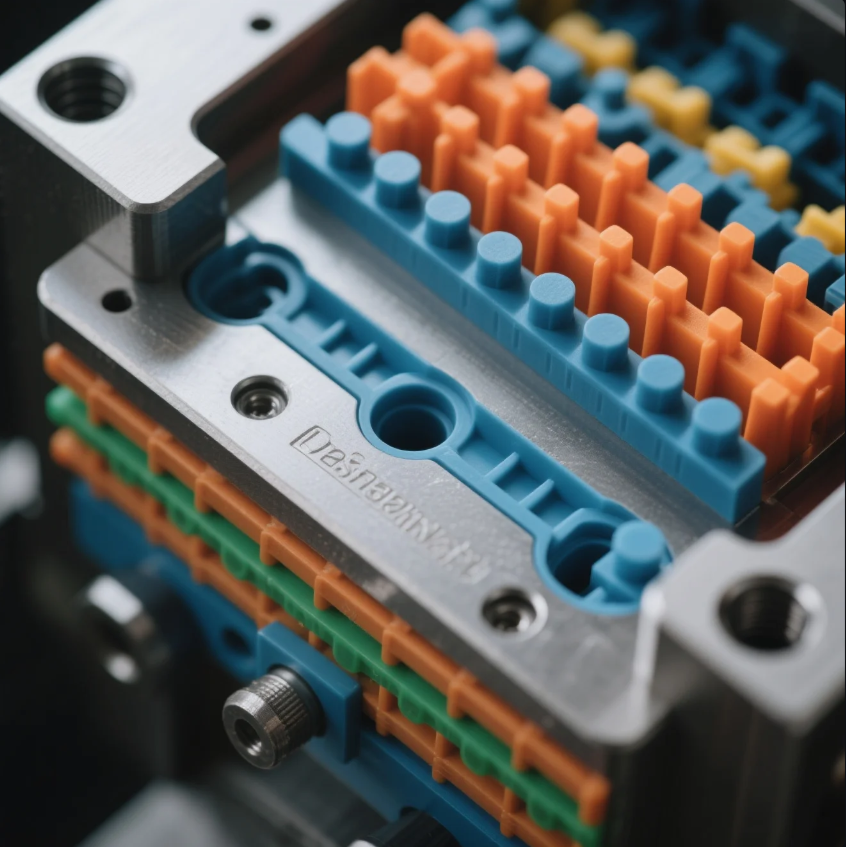

Is plastic injection molding difficult?

It may seem automated, but molding involves multiple variables and real-time troubleshooting.

Plastic injection molding is not easy — it requires control over pressure, temperature, timing, and mold maintenance.

At Prime, our experienced technicians handle 10+ production lines. From resin drying to part ejection, each step must be precise for ISO-certified plastic parts.

Why Molding Requires Skill

| Variable | Why It Matters |

|---|---|

| Temperature control | Affects flow and part quality |

| Pressure setting | Impacts fill and shrinkage |

| Cooling rate | Influences warping and strength |

| Mold setup | Determines cycle time and yield |

Despite automation, expert oversight is essential — something we’ve mastered over 20+ years.

What is a cheaper alternative to injection moulding?

Startups and short-run buyers often seek alternatives before committing to high tooling costs.

Cheaper alternatives include 3D printing, urethane casting, and thermoforming — best for low-volume or prototyping needs.

We supported a client with 3D-printed pilot runs, then shifted them to injection molding at Prime when their volumes crossed 2,000 units.

Low-Cost Molding Alternatives

| Method | Best Use Case | Volume Range |

|---|---|---|

| 3D Printing | Prototypes, 1–100 pcs | Very low volume |

| Urethane Casting | Soft tools, 100–500 pcs | Mid-volume |

| Thermoforming | Thin parts, 500–5000 pcs | Large, flat items |

These methods are ideal for MVPs and pre-production trials — before scaling to Prime’s custom injection molding solutions.

Conclusion

Polypropylene is the easiest plastic to mold — and ideal for simple parts, fast cycles, and low-cost tooling.

Need help choosing an easy-to-mold resin or reducing tooling costs? Prime offers free DFM feedback, custom part design, and low-cost mold options. Contact us now for a quote or material consultation, and we’ll help you launch faster — with quality built in.