What is the best plastic for making parts?

Choosing the best plastic often leads to confusion and costly mistakes.

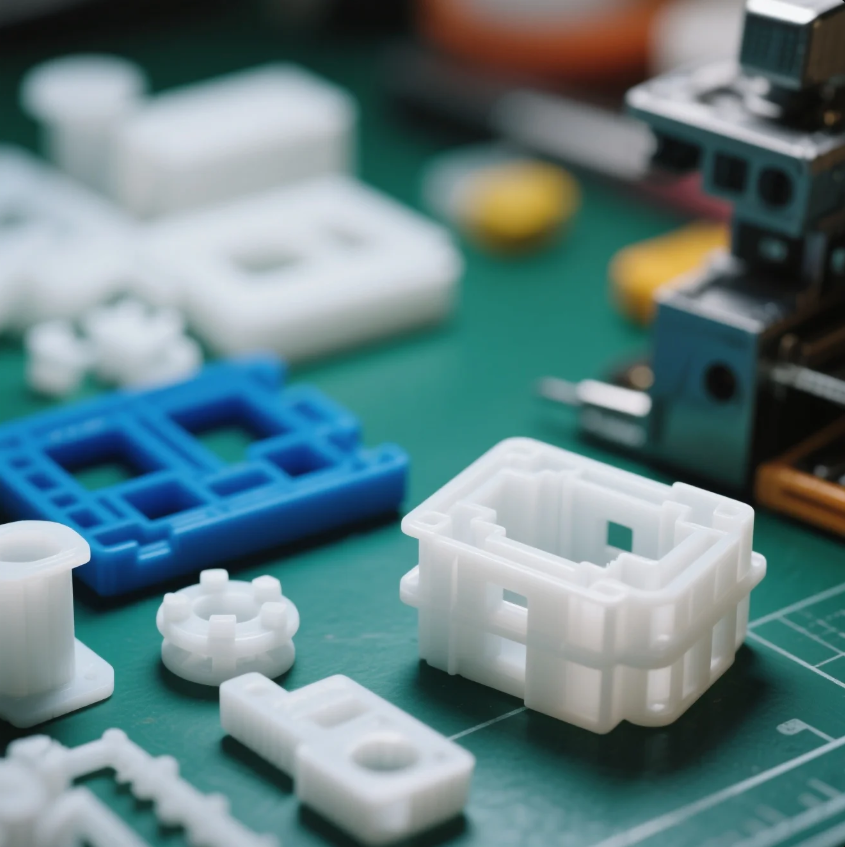

The best plastic depends on your product’s purpose, strength needs, and production method. Common choices include ABS, PP, PC, Nylon, and PEEK.

Selecting the right plastic reduces failures, lowers cost, and improves performance.

Still unsure which plastic to choose? Let’s break it down, step by step.

What is the easiest plastic to injection mold?

Many clients want quick results, but they struggle with long mold cycles and rejects.

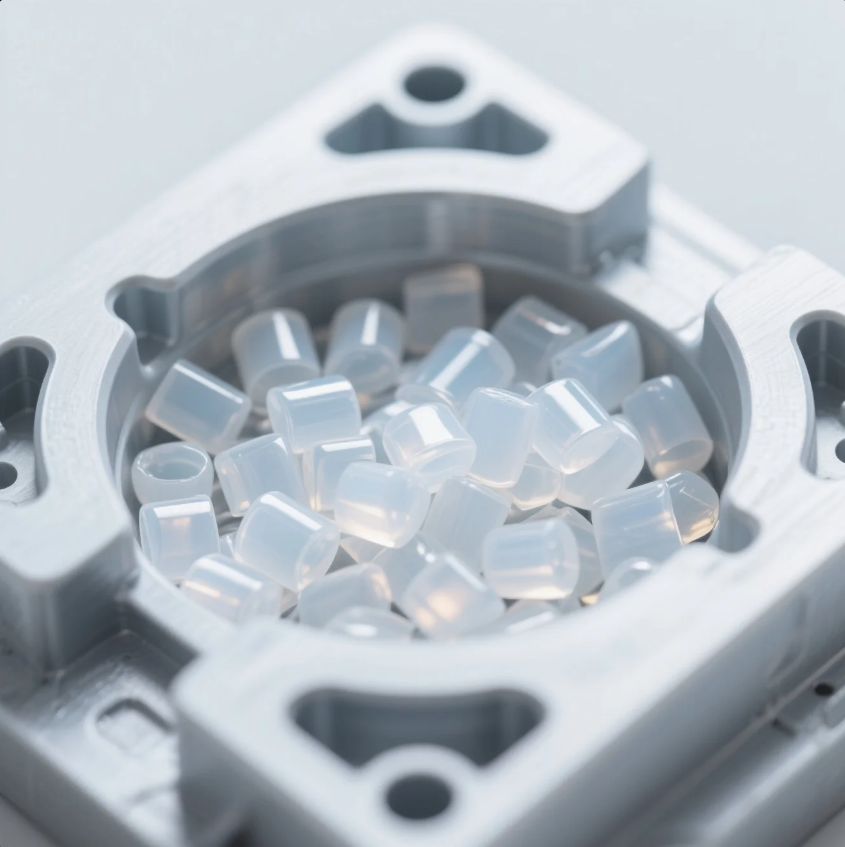

Polypropylene (PP) and Polyethylene (PE) are the easiest plastics to mold. They flow well and shrink evenly.

PP and PE allow fast cycles, fewer defects, and smooth finishes. That makes them perfect for large-scale production.

Why PP and PE Are Easy to Mold

| Plastic | Melt Temp | Flow Rate | Shrinkage | Application |

|---|---|---|---|---|

| PP | \~160°C | Excellent | Predictable | Caps, containers |

| PE | \~130°C | High | Stable | Toys, bottles |

At Prime, we often use PP and PE for cost-sensitive parts. Our team delivers finished goods in as little as 7 working days.

What is the strongest plastic for injection molding?

Parts used in tough environments need strength, but many plastics can't handle stress or heat.

Polycarbonate (PC) and Nylon are top picks for strength. They resist impact, pressure, and wear.

Both offer high mechanical performance, making them ideal for automotive, tools, and industrial housings.

Comparing Strong Plastics

| Plastic | Impact Resistance | Heat Resistance | Flexibility | Use Cases |

|---|---|---|---|---|

| PC | Extremely High | Up to 135°C | Medium | Covers, safety parts |

| Nylon | Very High | Up to 120°C | High | Gears, levers |

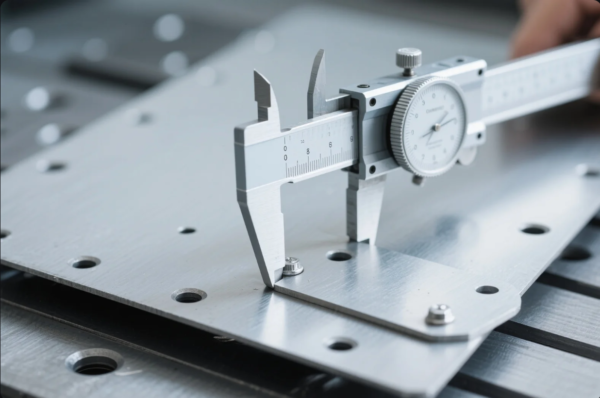

Prime supports both materials with tight tolerance CNC molds and ISO-certified molding lines, ensuring stable and strong output.

What is the highest quality plastic?

Some buyers want the “best of the best,” but don’t know what that means for plastic.

PEEK is considered the highest quality plastic. It offers extreme heat resistance, chemical stability, and mechanical strength.

It’s used in aerospace, medical, and high-end industrial applications. But it’s also expensive and harder to mold.

Why PEEK Stands Out

| Feature | PEEK Value | Other Plastics |

|---|---|---|

| Temp Resistance | Up to 260°C | <150°C |

| Tensile Strength | \~100 MPa | 30–70 MPa |

| Chemical Resistance | Excellent | Moderate |

| Cost | High | Low–Mid |

We work with PEEK upon request, especially for medical clients and global engineers needing extreme reliability.

What is the best plastic for car parts?

Automotive parts need a balance of strength, durability, and weight. Not all plastics qualify.

ABS, Nylon, PC/ABS blends, and PP are commonly used for car parts. Each serves a specific role in safety, interior, or under-the-hood applications.

Automotive Plastic Options

| Plastic | Common Use | Key Traits |

|---|---|---|

| ABS | Dashboards, trims | Durable, rigid |

| Nylon | Engine covers, gears | Heat-resistant |

| PC/ABS | Airbag housings | Impact + flex |

| PP | Bumpers, liners | Lightweight |

Prime has supported Tier 1 and Tier 2 automotive suppliers for years, offering custom injection services, quality control, and fast lead times for bulk orders.

Conclusion

The best plastic depends on your application. For easy molding, go with PP. For strength, choose PC or Nylon. For premium needs, PEEK leads the way.

Need help selecting the best plastic for your parts? Contact Prime today through our website. Get a free consultation and quote, and enjoy fast, reliable, and ISO-certified production trusted by global clients.