What is the difference between sheet metal and plate metal?

Many buyers confuse sheet metal with plate metal and make poor sourcing choices.

The main difference is thickness: sheet metal is thinner than plate metal. This affects strength, weight, and application.

Let’s break down each type and how it fits into real-world manufacturing needs.

What is the difference between MS plate and sheet?

Some clients use “MS plate” and “MS sheet” as if they mean the same thing.

MS (Mild Steel) sheet is thinner and used for lighter applications. MS plate is thicker and handles heavier loads.

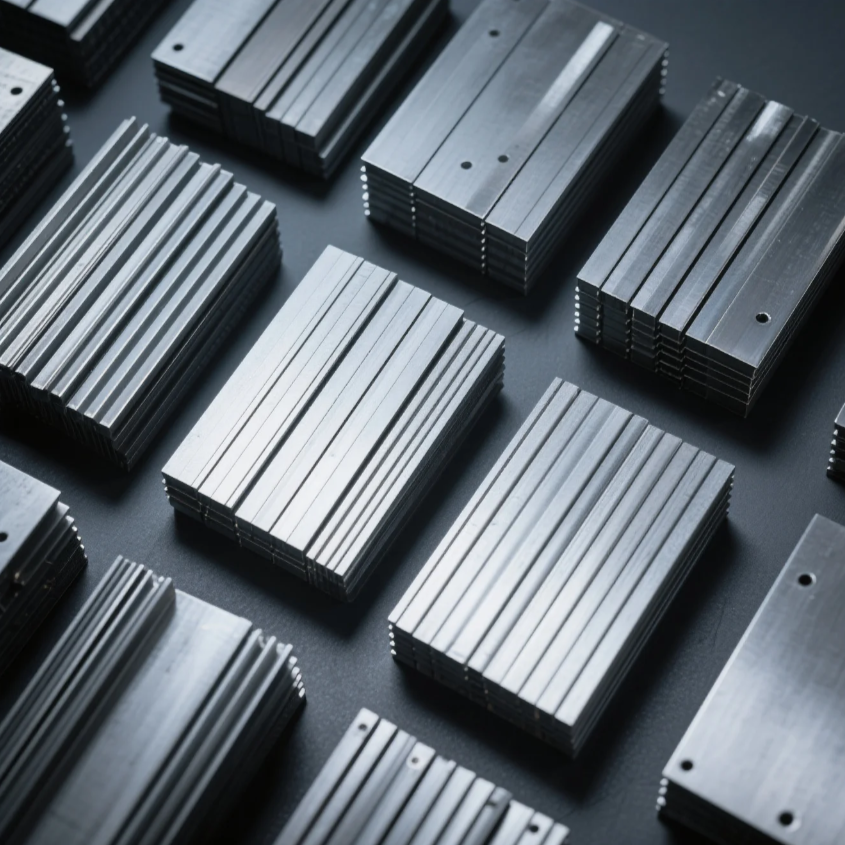

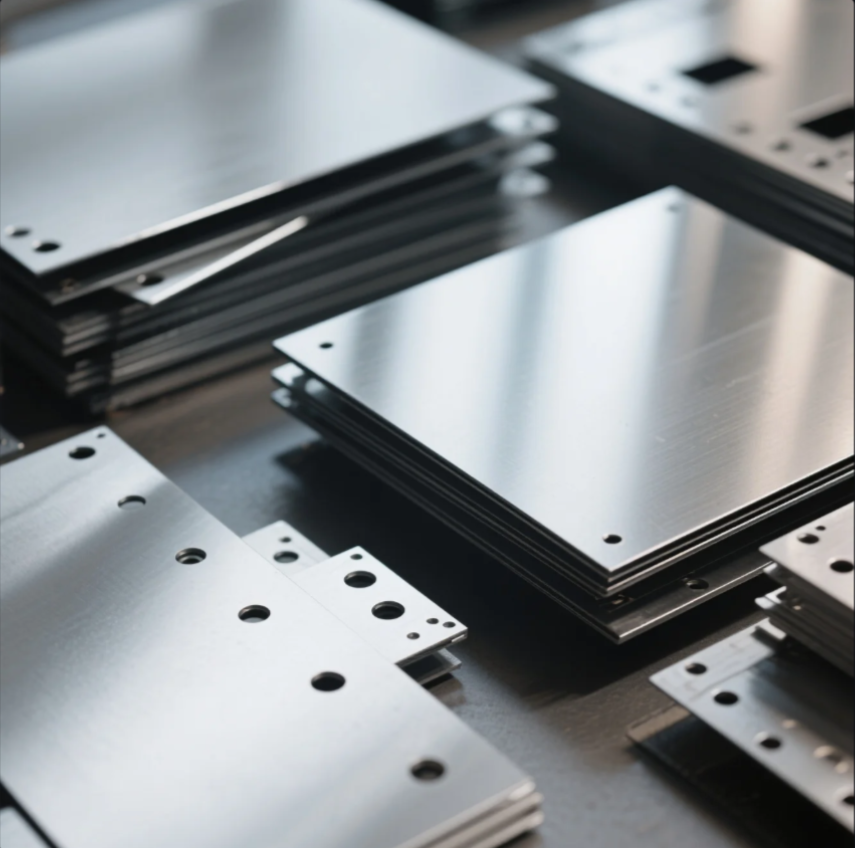

MS sheets are usually less than 6mm thick. They work well for panels, covers, or enclosures. MS plates are over 6mm thick and used in structural or load-bearing parts. At Prime, we process both forms. Our stamping parts often start from MS sheet, while our welding assemblies may use plate for better strength.

MS Sheet vs MS Plate

| Feature | MS Sheet | MS Plate |

|---|---|---|

| Thickness | Usually < 6mm | Usually > 6mm |

| Usage | Ducts, covers, light frames | Beams, heavy-duty parts |

| Weight | Lighter | Heavier |

| Processing | Easier to bend/form | Requires more force/tools |

We help clients choose the right thickness for their designs to avoid over-engineering or failure.

What is the difference between aluminum plate and sheet?

Lightweight needs bring up another common question: aluminum plate vs aluminum sheet.

Aluminum sheet is thin and flexible. Aluminum plate is thicker, offering more strength and rigidity.

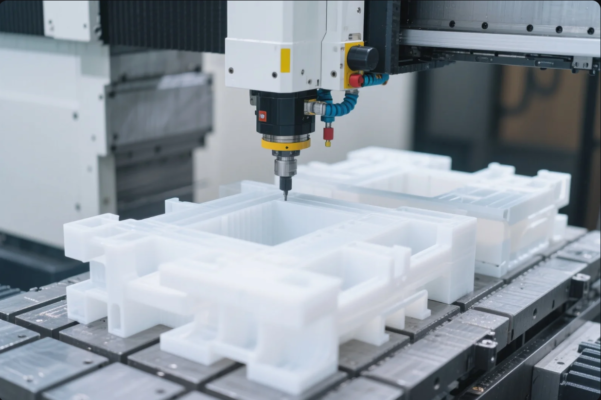

Sheets are typically under 6mm thick. Plates are 6mm and above. Aluminum sheets are common in electronic housings or decorative panels. Aluminum plates are used in aerospace, marine, or structural applications. At Prime, we supply both, offering laser cutting and CNC machining to exact specs.

Aluminum Sheet vs Plate Comparison

| Property | Aluminum Sheet | Aluminum Plate |

|---|---|---|

| Thickness | < 6mm | ≥ 6mm |

| Flexibility | Higher | Lower |

| Strength | Medium | High |

| Common Use | Appliances, signage | Aircraft, ships, machinery |

We offer brushed, anodized, and powder-coated finishes on both types depending on project needs.

What is the difference between plate, sheet, and strip?

Buyers often see “plate,” “sheet,” and “strip” used together—but they mean different things.

Thickness and width separate plate, sheet, and strip. Plate is thickest, strip is narrowest, sheet is in between.

Strips are long, narrow, and thin—great for seals, shims, or edge trims. Sheets are broader and thinner, perfect for bending or stamping. Plates offer structural strength. At Prime, we cut coils into sheets and strips using automated feeding and shear systems. We help clients match material form to production efficiency.

Plate vs Sheet vs Strip

| Type | Thickness | Width | Common Use |

|---|---|---|---|

| Plate | > 6mm | Wide | Structural, load-bearing |

| Sheet | 0.5mm – 6mm | Medium | Enclosures, covers, casings |

| Strip | < 3mm | Narrow (custom) | Seals, springs, brackets |

We maintain raw material stock in all three formats for fast lead times and flexible order volumes.

What is the difference between sheet and plate in fitting shop?

In the fitting shop, using the wrong form increases waste and risk.

In a fitting shop, sheet is used for cutting and shaping light components. Plate is used for welding and load-bearing assemblies.

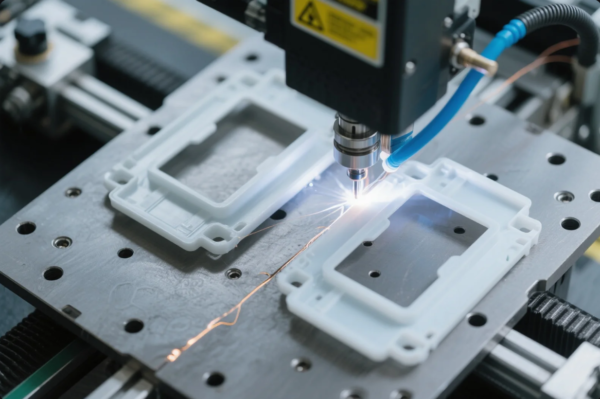

Sheet metal is easier to cut, bend, and punch. Plate metal needs heavier tools and is better for welded frames or base structures. At Prime, our fitting shop uses CNC shears for sheet work and plasma cutters for plates. We prepare all components for fast assembly or welding on the customer’s side.

Workshop Handling Differences

| Task | Sheet Handling | Plate Handling |

|---|---|---|

| Cutting | Shears, laser, punches | Plasma or oxy-fuel cutters |

| Assembly | Bolting or light welding | Heavy welding, structural fit-up |

| Movement | Manual or light tools | Cranes, forklifts |

| Application | Light covers, panels | Machine bases, support plates |

We also support kitted delivery—labelled, matched, and ready for assembly on arrival.

Conclusion

Sheet metal and plate metal differ in thickness, strength, and how they are used in manufacturing.

Need help choosing the right material form? Contact Prime today for a free consultation and detailed quote. We supply ISO-certified sheet, plate, and strip parts—customized to your project, delivered on time, worldwide.