What is stamping metal called?

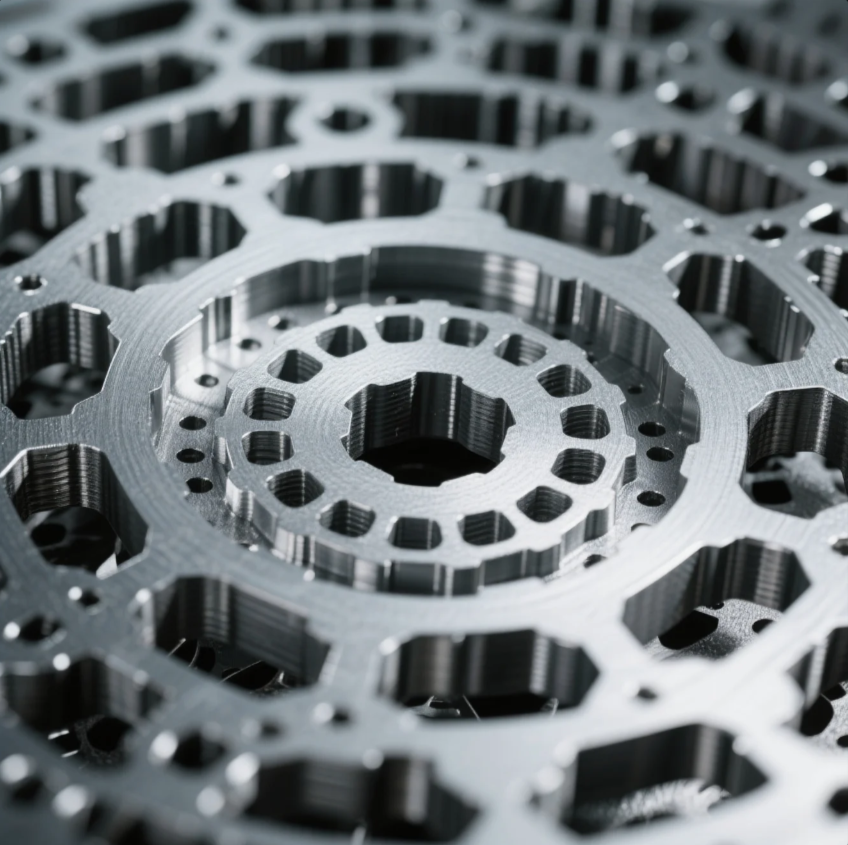

Stamping metal is more than just pressing—it’s a precise industrial process with many applications.

Stamping metal is called metal stamping or press working. It forms metal sheets into parts using dies and presses.

In this article, I’ll break down the terminology, processes, tools, and materials used in stamping—plus how Prime delivers high-quality stamped parts for industrial clients worldwide.

What is a stamping machine called?

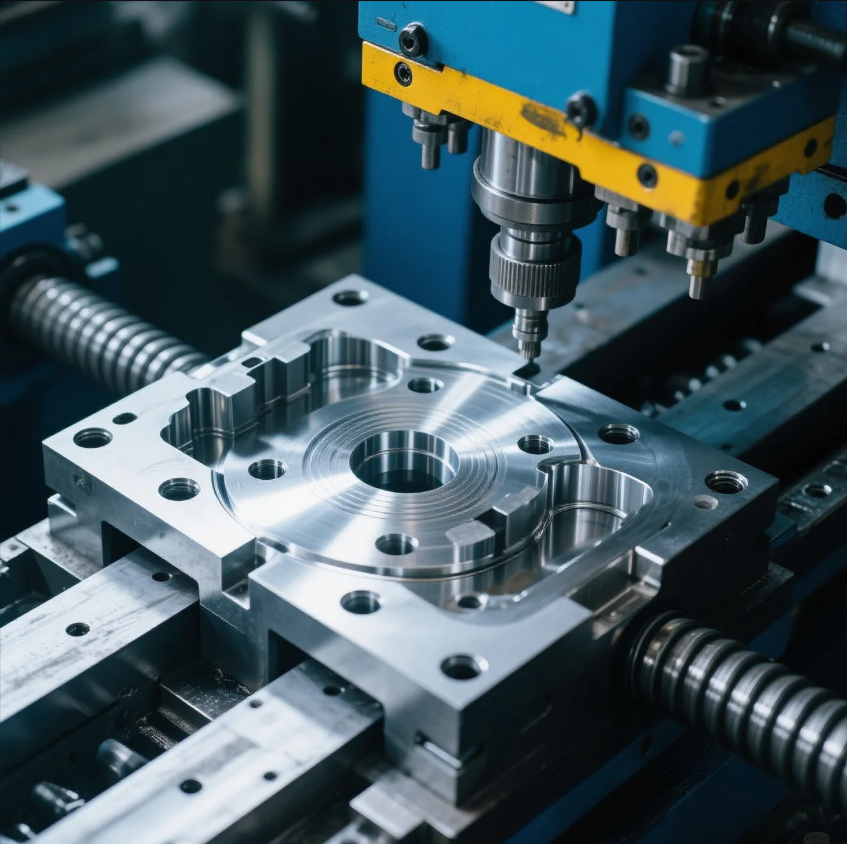

Stamping metal requires a machine with force. This machine is often called a press.

A stamping machine is called a press. It can be mechanical, hydraulic, servo, or pneumatic depending on the job.

Different names for the same powerful tool

You might hear different terms used in the industry:

| Machine Name | Description |

|---|---|

| Press Machine | General term for stamping machine |

| Mechanical Press | Uses flywheel and crank system |

| Hydraulic Press | Uses fluid pressure for deeper drawing |

| Servo Press | Uses programmable motor for precision |

| Punch Press | Used for cutting holes or shapes |

At Shandong Prime, we run 10 production lines with multiple press types, allowing us to meet complex stamping needs for mining, machinery, and construction clients.

What are the four types of metal stamping?

There’s more than one way to stamp metal. Different techniques serve different part designs.

The four types of metal stamping are progressive die, transfer die, four-slide, and deep draw. Each offers unique advantages.

Choosing the right stamping method for your parts

Here’s how each type works:

| Stamping Type | Function | Best Use Case |

|---|---|---|

| Progressive Die | Multiple operations in one stroke | High-speed, detailed parts |

| Transfer Die | Moves part between dies automatically | Large or deep-formed components |

| Four-Slide | Multiple directions of bending and cutting | Small, intricate parts |

| Deep Draw | Pulls metal into a deep hollow shape | Cups, cans, filter housings |

For example, when a client needs 定制冲压件 with high complexity and fast delivery, we often use progressive die stamping to save cost and time.

What material is used for stamping?

Not all metals are good for stamping. The right choice balances strength, formability, and cost.

Common stamping materials include carbon steel, stainless steel, aluminum, brass, and copper. Material choice depends on part function.

How to choose the best stamping material

We help clients choose based on:

- Strength needed

- Corrosion resistance

- Cost target

- Compatibility with surface treatments

| Material | Best For | Properties |

|---|---|---|

| Carbon Steel | Structural parts, brackets | Strong, cost-effective |

| Stainless Steel | Corrosion-prone environments | Rust-resistant, durable |

| Aluminum | Lightweight parts, enclosures | Light, easy to form |

| Brass / Copper | Decorative or conductive uses | Good appearance, high conductivity |

At Prime, we provide full traceability and material certificates for all stamping parts, ensuring compliance with client specs and ISO certification requirements.

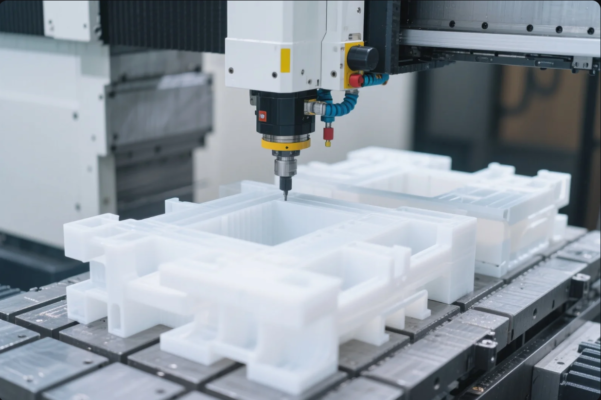

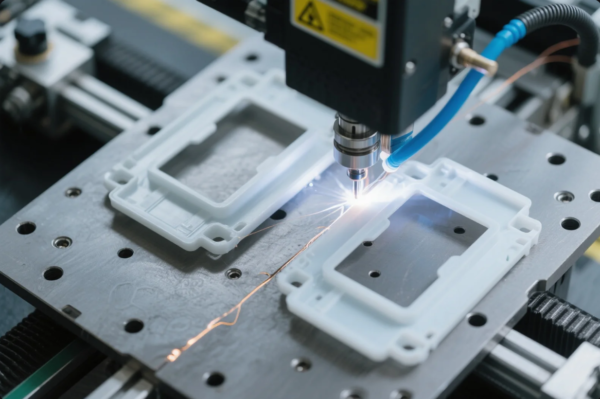

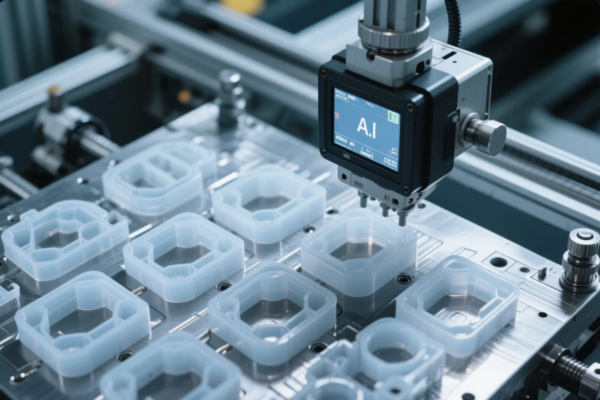

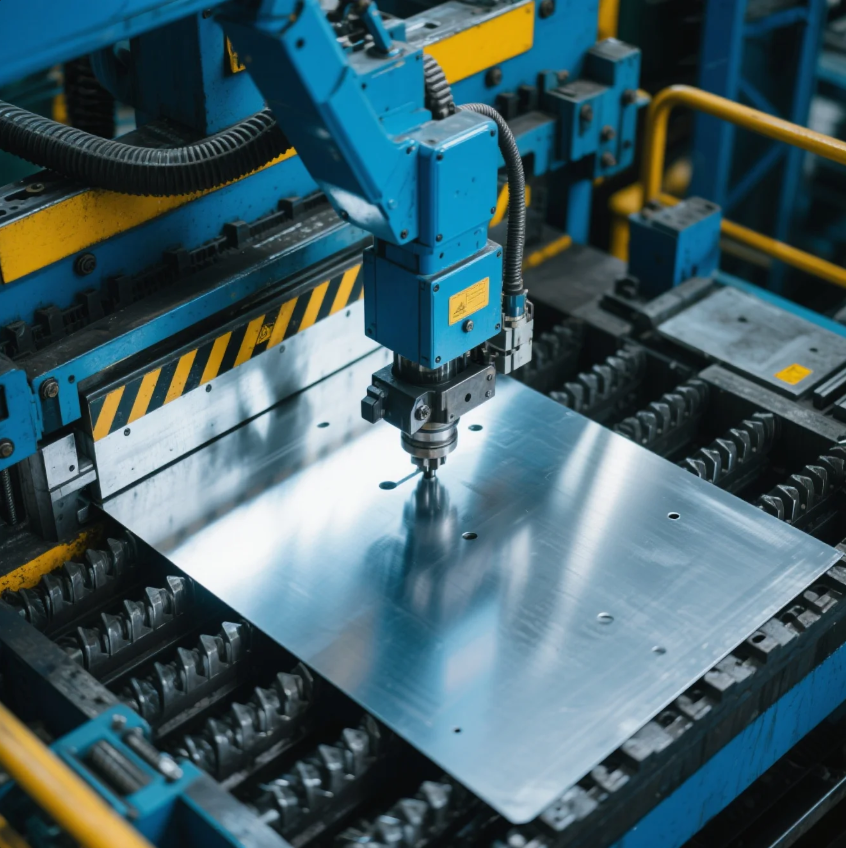

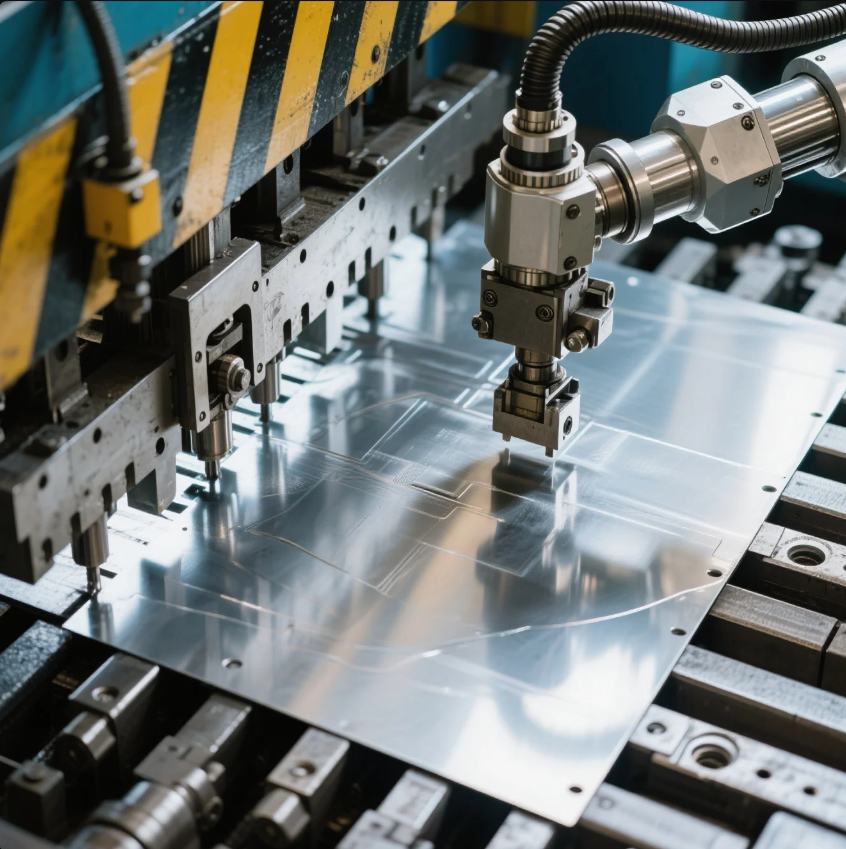

What equipment is used for stamping?

Stamping equipment includes more than just the press. It’s a system that feeds, forms, and inspects.

Stamping setups use a press, a die set, feeders, ejection systems, and quality control tools.

The full stamping equipment list

| Equipment Component | Purpose |

|---|---|

| Press Machine | Provides the forming force |

| Die Set | Shapes and cuts the metal |

| Coil Feeder | Feeds continuous sheet metal into press |

| Ejector / Sorter | Removes finished parts |

| Inspection Tools | Ensures quality (calipers, gauges, cameras) |

Our stamping lines are integrated with real-time quality checks and automated sorting, ensuring every part meets your tolerance and surface specs. We also combine stamping with CNC零件精准加工 for post-process refinement when needed.

Conclusion

Stamping metal—also called press working—uses presses and dies to form high-precision parts at scale.

Looking for a trusted metal stamping supplier with full capabilities and global delivery? Contact Shandong Prime International Trade Co., Ltd. today. We offer free design feedback, custom tooling, and ISO-certified production to support your industrial stamping needs. Send us your RFQ and let’s build durable, efficient parts—together.