How to cut thick metal fast?

Cutting thick metal is tough—but with the right tools, it can be done quickly and cleanly.

The fastest way to cut thick metal is using a plasma cutter or an industrial band saw. For precision, waterjet and laser cutters also work well.

In this guide, I’ll explain the most effective tools and machines for fast, accurate thick metal cutting—and how Prime handles heavy-duty metal parts for industrial applications.

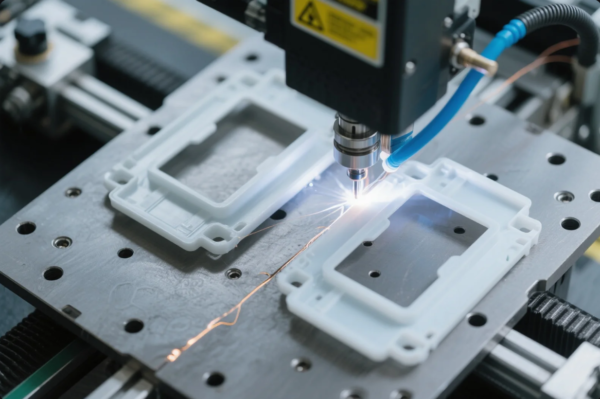

What cuts through metal the fastest?

Speed matters when cutting heavy materials. Some tools are built just for this.

A plasma cutter is the fastest tool for cutting through thick metal, especially steel and alloy plates.

Why plasma cutting is the fastest method

- Uses high-temperature ionized gas

- Cuts steel up to 50mm thick

- Works on rough, rusty, or painted surfaces

| Tool | Cutting Speed | Thickness Capability |

|---|---|---|

| Plasma Cutter | Very high | Up to 50mm or more |

| Oxy-Fuel Torch | High | Up to 150mm steel |

| Abrasive Chop Saw | Medium | Up to 100mm pipes/bars |

At Prime, we use plasma cutting for fast layout work, followed by CNC零件精准加工 when tight tolerances are needed.

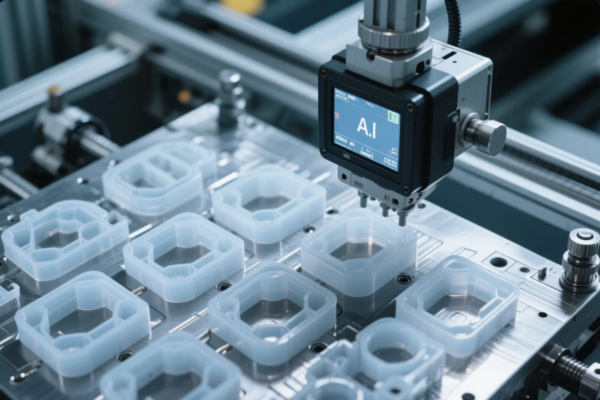

What is the best cutter for thick metal?

Not every tool handles thick metal well. Some cut fast, others cut clean.

For clean, thick metal cutting, the best options are plasma cutters, cold saws, and industrial band saws.

Choosing the best cutter based on your goal

| Goal | Best Tool | Notes |

|---|---|---|

| Fastest rough cut | Plasma cutter | High-speed, not as precise |

| Clean, accurate cut | Cold saw or band saw | Slower but smoother results |

| No heat deformation | Waterjet or cold saw | Best for heat-sensitive metals |

We help our clients choose based on order size and part spec. When cutting structural plates or tubes for mining equipment, we often use band saws combined with custom stamping for efficiency.

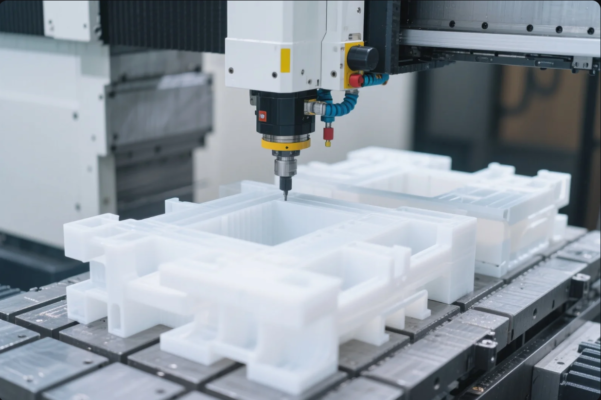

Which machine is used to cut thick metal?

Industrial machines handle thick metal with power and precision.

Machines used to cut thick metal include plasma cutters, oxy-fuel torches, band saws, waterjet cutters, and hydraulic shears.

Industrial cutting machines for heavy metal

| Machine Type | Cutting Method | Best For |

|---|---|---|

| Plasma Cutter | High-heat gas arc | Thick steel and alloy sheets |

| Oxy-Fuel Torch | Combustion flame | Very thick, structural steel |

| Band Saw | Blade slicing motion | Round bars, I-beams, profiles |

| Waterjet Cutter | High-pressure abrasive stream | Thick, heat-sensitive metals |

At Prime, we use multiple machines across 10 production lines, depending on the part’s material and thickness. Every part is cut, labeled, and inspected before shipping.

How thick of metal can a jigsaw cut?

Jigsaws are great for curves—but not for heavy-duty tasks.

A jigsaw can cut metal up to about 5–10mm thick, depending on the blade and material.

Limits of using a jigsaw for thick metal

- Works best on soft metals like aluminum

- Blades wear out quickly on steel

- Requires secure clamping to avoid vibration

| Material Type | Max Thickness (Approx.) | Notes |

|---|---|---|

| Aluminum | 10mm | Use fine-toothed blade |

| Mild Steel | 5–6mm | Slow feed, coolant recommended |

| Stainless Steel | 3–4mm | Only with carbide blades |

For anything thicker, switch to angle grinders, band saws, or plasma cutters. We only use jigsaws for small prototype work—never for industrial parts.

Conclusion

Plasma cutters and band saws are the fastest, most effective tools for cutting thick metal—especially in industrial production.

Need thick metal parts cut quickly and precisely? Contact Shandong Prime International Trade Co., Ltd. today. We offer plasma cutting, CNC machining, and ISO-certified production with fast global delivery. Let’s build tough, custom parts—ready for your heaviest applications.