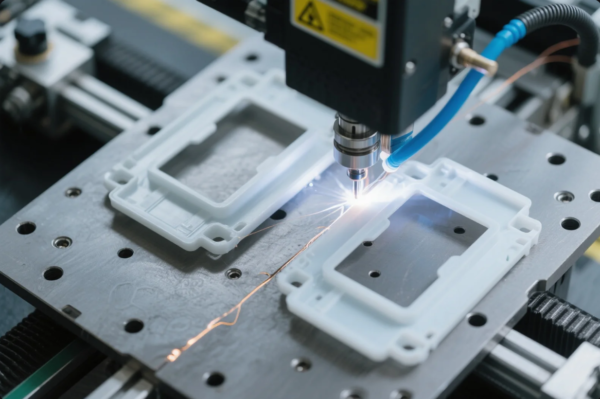

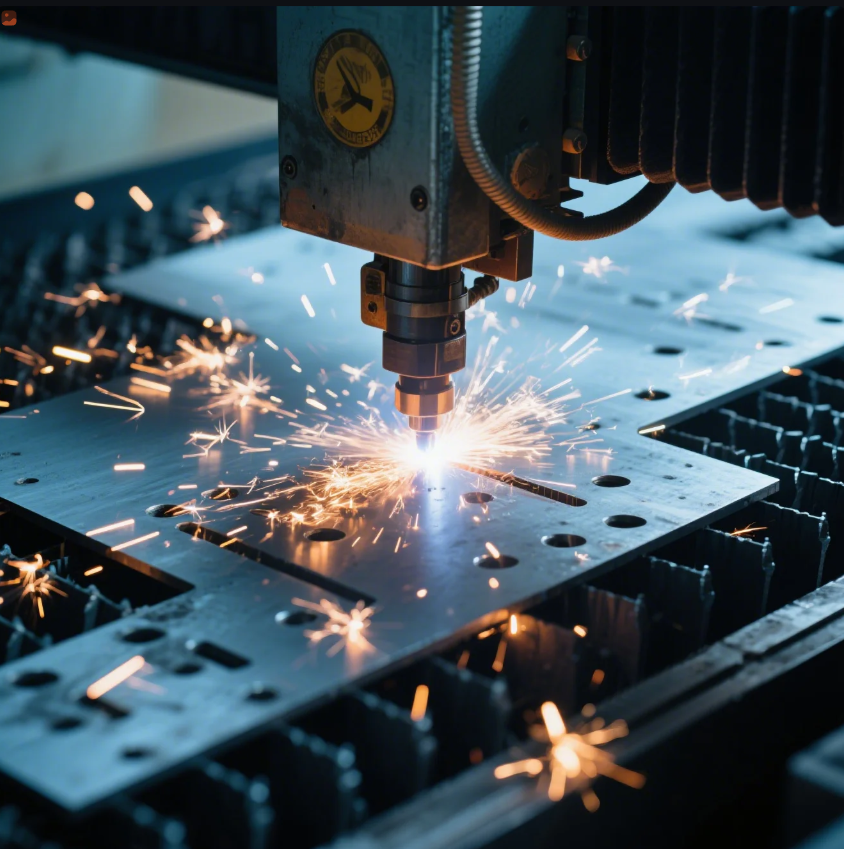

How powerful laser to cut metal?

Not all lasers are created equal—cutting metal requires serious power and the right wavelength.

To cut metal effectively, a laser needs at least 500W for thin sheets and 1000W or more for industrial use. Thicker metals require higher power and better optics.

In this article, I’ll break down how laser power affects metal cutting performance, the limits of low-wattage lasers, and what we use at Prime for precision laser-cut parts.

How powerful does a laser need to be to cut metal?

Laser cutting metal requires more energy than plastics or wood.

A laser needs at least 500–1000W to cut thin metal sheets and over 2000W to handle thicker materials.

Recommended laser power levels by metal type

| Material | Recommended Laser Power | Max Thickness (Single Pass) |

|---|---|---|

| Mild Steel | 1000W – 4000W | Up to 20mm |

| Stainless Steel | 1500W – 6000W | Up to 25mm |

| Aluminum | 2000W – 6000W (fiber laser) | Up to 16mm |

| Copper/Brass | 2000W+ (with fiber laser) | Up to 8–10mm |

At Prime, we use high-powered fiber laser systems (3kW–6kW) for cutting stainless steel, aluminum, and alloy parts with clean edges and minimal burrs.

Can a 100W laser cut metal?

100W might sound strong—but it’s not enough for real metal cutting.

A 100W laser cannot cut metal. It’s only suitable for engraving or cutting soft materials like plastic or wood.

Why 100W lasers aren’t made for metal

- Not enough heat density to melt or vaporize metal

- Cannot maintain stable beam focus on reflective surfaces

- Lacks cutting speed and depth even on thin foil

| Wattage | Material Capability | Limitation |

|---|---|---|

| 100W CO2 | Plastics, wood, leather | Can’t penetrate metals |

| 100W Fiber | Metal marking, not cutting | Cuts only extremely thin foil (\~0.1mm) |

For cutting even 1mm thick stainless steel, you need at least a 500–1000W fiber laser with proper gas shielding and lens calibration.

What is the thickest metal a laser can cut?

Laser cutting has limits—especially on reflective and thick materials.

High-power fiber lasers (12kW+) can cut steel up to 40–50mm thick under perfect conditions, but 20–25mm is the practical limit in most shops.

Real-world limits of laser thickness

| Metal Type | Max Practical Thickness | Notes |

|---|---|---|

| Mild Steel (O2 assist) | 25mm | Smooth edge, clean kerf |

| Stainless Steel | 20mm | Nitrogen gas preferred for clean cuts |

| Aluminum | 16mm | Needs high power and stable cooling |

| Copper/Brass | 8–10mm | Requires high-power fiber + beam control |

At Prime, we cut carbon steel up to 20mm and stainless steel up to 16mm using 6000W fiber lasers, followed by CNC零件精准加工 for finishing.

What can a 1000W laser cut?

A 1000W fiber laser is the starting point for industrial sheet metal work.

A 1000W laser can cut mild steel up to 6–8mm, stainless steel up to 4mm, and aluminum up to 2–3mm with moderate speed.

Typical capabilities of a 1000W laser

| Material | Max Thickness (Clean Cut) | Notes |

|---|---|---|

| Mild Steel | 6–8mm | Best with oxygen assist gas |

| Stainless Steel | 3–4mm | Use nitrogen to avoid oxidation |

| Aluminum | 2–3mm | Reflective—slower speed recommended |

For thicker cuts, we recommend 2000W–6000W lasers, which we use daily at Prime to produce precision metal stamping blanks, enclosures, and structural panels.

Conclusion

To cut metal, you need at least 1000W. For thick or reflective metals, 3000W+ fiber lasers are ideal.

Need fast, clean laser-cut parts? Contact Shandong Prime International Trade Co., Ltd. today. We offer high-power laser cutting, tight tolerances, and ISO-certified production with global delivery. Send us your drawings—let’s cut with confidence.