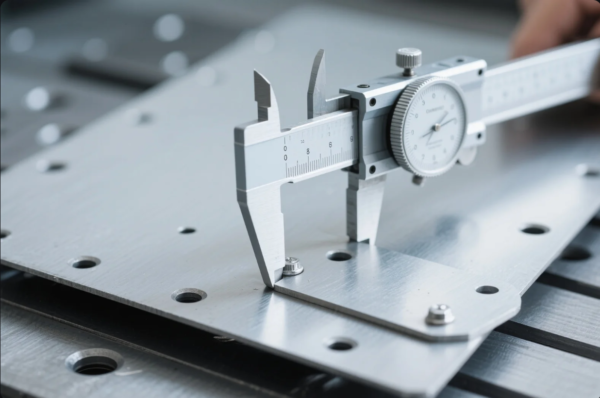

What are the bend rules for sheet metal?

Getting the bends wrong in sheet metal design can destroy fit, function, or even the part itself.

Bend rules in sheet metal design help ensure clean, crack-free bends by setting guidelines for bend radius, hole spacing, relief, and flange length.

At Prime, we apply these rules to every custom sheet metal part—making sure your drawings turn into perfect parts.

What is the rule for bending sheet metal?

If your bend radius is too tight, you’ll get cracks or wrinkles.

Use a bend radius at least equal to the material thickness. For tougher materials, go higher to prevent stress and cracking.

At Prime, we run simulations before cutting metal. That saves you from failed prototypes and helps meet ISO fabrication standards.

Key Bend Rules

| Element | Recommended Value |

|---|---|

| Inside Bend Radius | ≥ 1 × material thickness |

| Minimum Flange | ≥ 4 × material thickness |

| Relief Width | ≥ material thickness |

| Bend Direction | With grain (for less cracking) |

Following these basic bend rules ensures durability and simplifies manufacturing.

How close can a hole be to a sheet metal bend?

Too-close holes deform during bending—and may break your tools.

Keep holes at least 2× material thickness away from the bend line. Go 3× for better safety, especially in thick sheets.

At Prime, we run every drawing through a DFM check before tool setup, catching poor hole placement early.

Hole Distance Guidelines

| Material Thickness | Min Hole-to-Bend Distance |

|---|---|

| 1.0 mm | 2.0 – 3.0 mm |

| 1.5 mm | 3.0 – 4.5 mm |

| 2.0 mm | 4.0 – 6.0 mm |

| 3.0 mm | 6.0 – 9.0 mm |

Need tight layouts? We may recommend alternate tooling or laser cutting instead of punching.

What are the standards for bending sheet metal?

Without standard rules, your part may bend wrong—even if it looks good in CAD.

Standards cover bend allowance, relief design, material type, and flange tolerances. International codes like ISO 2768 and DIN 6935 guide precision parts.

At Prime, we manufacture to ISO and DIN standards, giving you global quality compliance and reliable part-to-part consistency.

Common Sheet Metal Bending Standards

| Standard | Description |

|---|---|

| ISO 2768 | General tolerances for dimensions |

| DIN 6935 | Design rules for press brake parts |

| K-Factor Guide | Adjusts flat pattern for bend stretch |

| Bend Deduction | Calculates total material consumption |

We help clients match the right tolerance class to their product use case—no guessing needed.

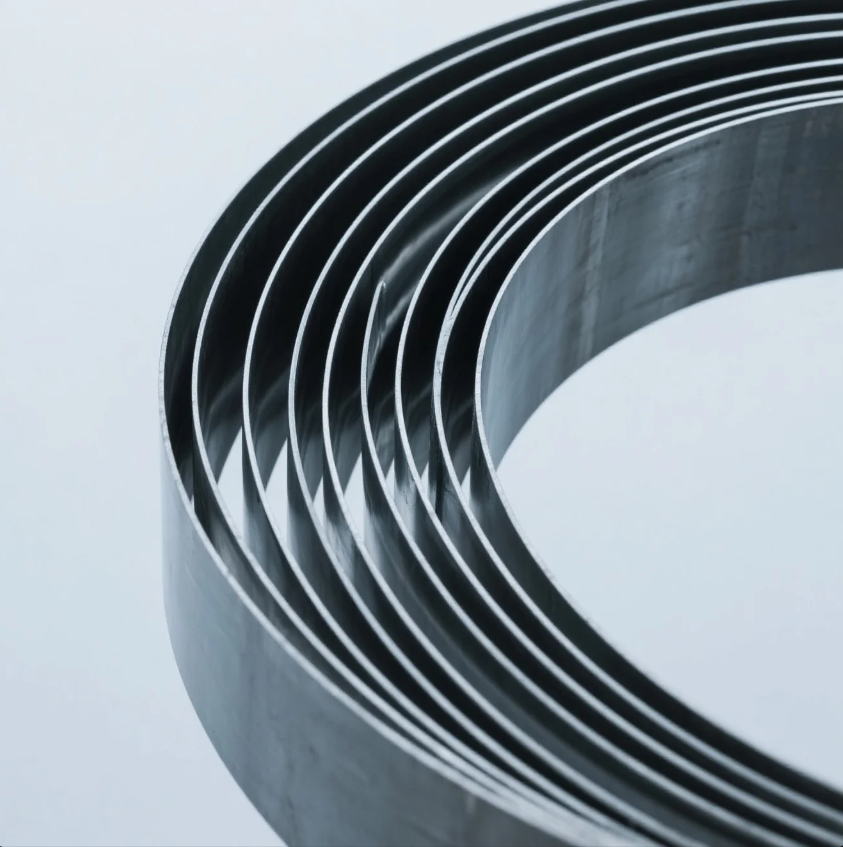

What is the minimum hole to bend sheet metal?

Even if a hole looks okay in CAD, it may fail in real production.

The minimum hole diameter should be at least 1.5× the material thickness. Smaller holes risk tearing, misalignment, or punch breakage.

Prime follows this rule for every stamped or CNC-fabricated part—because clean, consistent holes mean fewer rejected parts and lower production costs.

Minimum Hole Size Table

| Material Thickness | Minimum Hole Diameter |

|---|---|

| 0.8 mm | 1.2 mm |

| 1.0 mm | 1.5 mm |

| 1.5 mm | 2.3 mm |

| 2.0 mm | 3.0 mm |

We’ll alert you during quoting if hole sizes need revision—and suggest laser cutting if ultra-small features are needed.

Conclusion

Follow bend rules like radius = thickness, holes ≥2×T from bends, and proper reliefs to avoid costly production errors.

Need help finalizing your sheet metal part design? Prime offers free DFM checks, ISO-certified production, and precision bending for global clients. Contact us now for a quote and expert review—get your design right from the first bend.