What is the minimum thickness for sheet metal?

Designing parts too thin can cause cracking, distortion, or tool failure.

The minimum thickness for sheet metal is typically 0.5 mm for most applications. Below this, handling and forming become unstable without specialized equipment.

At Prime, we work with materials from 0.5 mm up to 6 mm, ensuring each thickness meets strength, tolerance, and forming requirements.

What is the minimum thickness of sheet metal?

Some projects demand ultra-thin parts—but how thin is too thin?

For general industrial use, the practical minimum thickness for sheet metal is 0.5 mm. Special applications can go as low as 0.2 mm using laser cutting or etching.

At Prime, we recommend 0.6–1.0 mm for durable stamped enclosures or custom brackets that don’t warp or tear during production.

Thickness Guidelines by Application

| Use Case | Recommended Thickness |

|---|---|

| Electronic covers | 0.5 – 0.8 mm |

| Automotive brackets | 1.0 – 2.0 mm |

| Machine enclosures | 1.5 – 3.0 mm |

| Structural frames | 3.0 – 6.0 mm |

If your part needs to be ultra-thin, we’ll help adjust the design to keep strength without increasing cost.

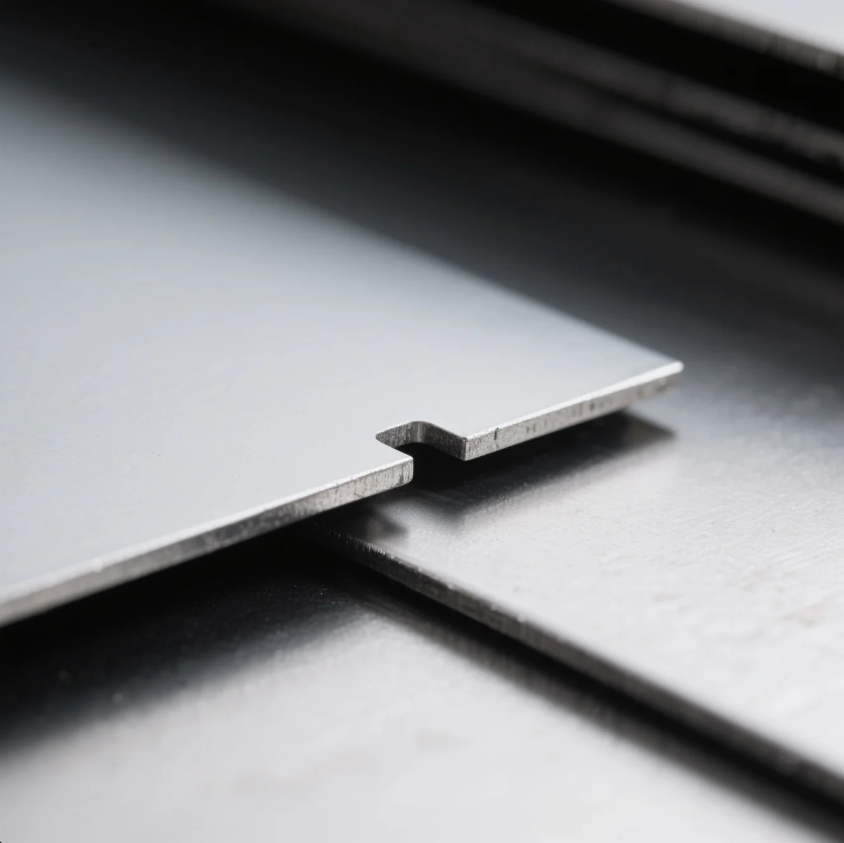

How thin can a sheet of metal be?

There’s a limit before a sheet becomes foil.

Technically, sheet metal ranges down to 0.2 mm. Thinner than that, it's considered foil, not sheet.

Prime handles sheet metals from 0.5 mm and up, using CNC cutting, laser forming, and high-precision tooling. We avoid deformation by using exact feed control and holding fixtures.

Metal Type and Minimum Thickness

| Material | Min. Practical Thickness |

|---|---|

| Aluminum | 0.4 mm |

| Stainless Steel | 0.5 mm |

| Mild Steel | 0.5 mm |

| Copper | 0.3 mm |

We often help buyers redesign fragile parts with reinforcement flanges or stiffer alloys—avoiding breakage during shipping or use.

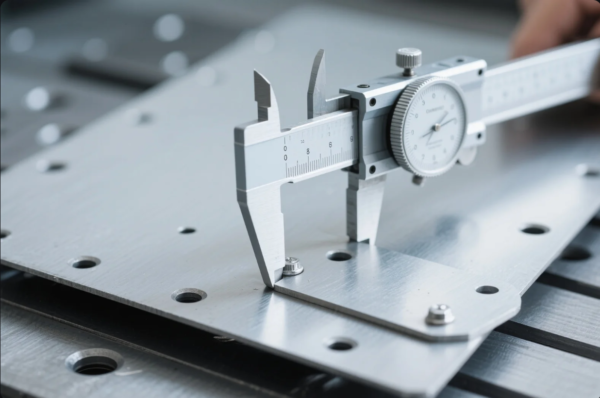

What thickness of sheet metal can you bend?

Bending thin material can be tricky—too thin and it creases, too thick and it cracks.

You can bend sheet metal from 0.5 mm up to 6 mm. Below 0.5 mm, creasing or distortion becomes hard to avoid without special dies.

At Prime, we use CNC press brakes that automatically adjust force based on thickness, so every bend lands right on spec.

Bend-Ready Thickness Range

| Thickness (mm) | Bendability Notes |

|---|---|

| 0.5 – 1.0 | Needs precise control, best with radius |

| 1.5 – 3.0 | Standard range, easily bendable |

| 4.0 – 6.0 | Requires stronger tooling, larger radii |

We also recommend increasing the inner bend radius to at least the material thickness to prevent cracking.

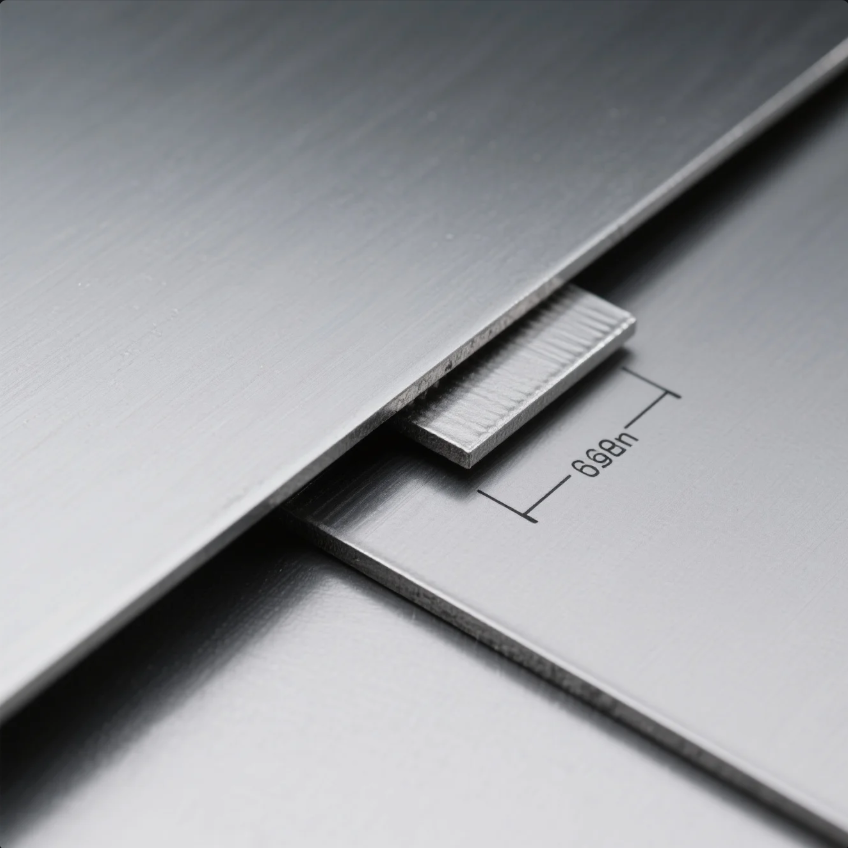

What is the minimum bend sheet metal?

Want crisp bends? Don’t make them too tight.

The minimum bend radius for sheet metal should equal the material thickness. Going smaller can cause cracks or springback.

Prime uses a digital tooling library and material specs to auto-calculate bend radius, flange length, and relief—ensuring tight, clean forms with no surprises.

Minimum Bend Radius Guide

| Material Thickness | Minimum Bend Radius |

|---|---|

| 0.5 mm | 0.5 mm |

| 1.0 mm | 1.0 mm |

| 2.0 mm | 2.0 mm |

| 3.0 mm | 3.0 mm |

Need tighter bends for compact designs? We’ll test and recommend alternate alloys or laser scoring to keep your shape intact.

Conclusion

Sheet metal should be at least 0.5 mm thick for safe forming and stable production.

Need help selecting the right thickness or adjusting your design? Prime offers ISO-certified sheet metal manufacturing, expert design reviews, and fast global delivery. Contact us now for a quote and professional guidance that saves you cost, time, and rework.