How do you smooth metal corners?

Sharp corners on metal parts can lead to safety hazards and failed inspections.

To smooth metal corners, use deburring tools, grinders, or rotary files to round sharp edges and ensure a clean finish.

At Prime, we smooth all punched, cut, and formed parts to meet safety and quality standards—especially for export-ready industrial components.

How to make metal edges smooth?

Cut edges often leave sharp burrs that are dangerous and unprofessional.

You can smooth metal edges by filing, sanding, or using power tools like belt grinders and flap wheels. The goal is to remove burrs and soften sharp points.

At Prime, we automate edge finishing on laser-cut, CNC-milled, and punched sheet metal parts, ensuring every edge is safe and production-ready.

Common Deburring Techniques

| Method | Best For |

|---|---|

| Manual Filing | Small runs, tight corners |

| Sanding Blocks | Light edges and finishing |

| Flap Discs | Medium burr removal |

| Belt Grinders | Long, straight edges |

| Tumbling/Vibratory | Small parts, batch processing |

We choose the method based on volume, part shape, and surface requirements.

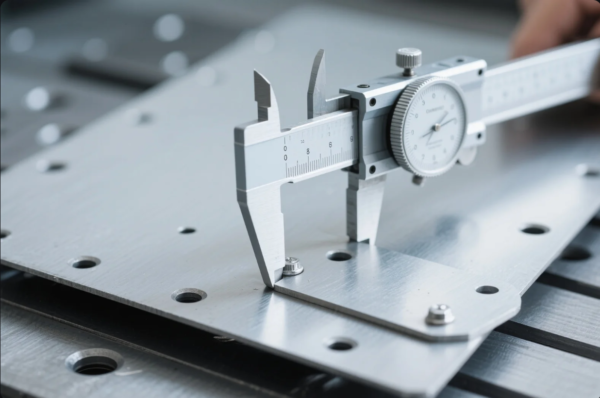

What is the best tool for smoothing edges on a piece of metal?

The right tool depends on your edge size, material, and finish needs.

The best tools for smoothing metal edges are belt grinders for straight runs and rotary deburring tools for internal curves or holes.

At Prime, we use a mix of automated and manual tools to finish custom sheet metal brackets, enclosures, and CNC-machined components.

Edge Smoothing Tool Guide

| Tool | Use Case |

|---|---|

| Belt Grinder | Long edges, medium-volume runs |

| Flap Wheel | Curved profiles, aluminum |

| Rotary File (Burr) | Internal corners, small holes |

| Scotch-Brite Wheel | Final finish, blending weld seams |

| Deburring Tool | Chamfering hole edges manually |

Need a cosmetic finish? We can apply brushing or polishing as part of the post-processing step.

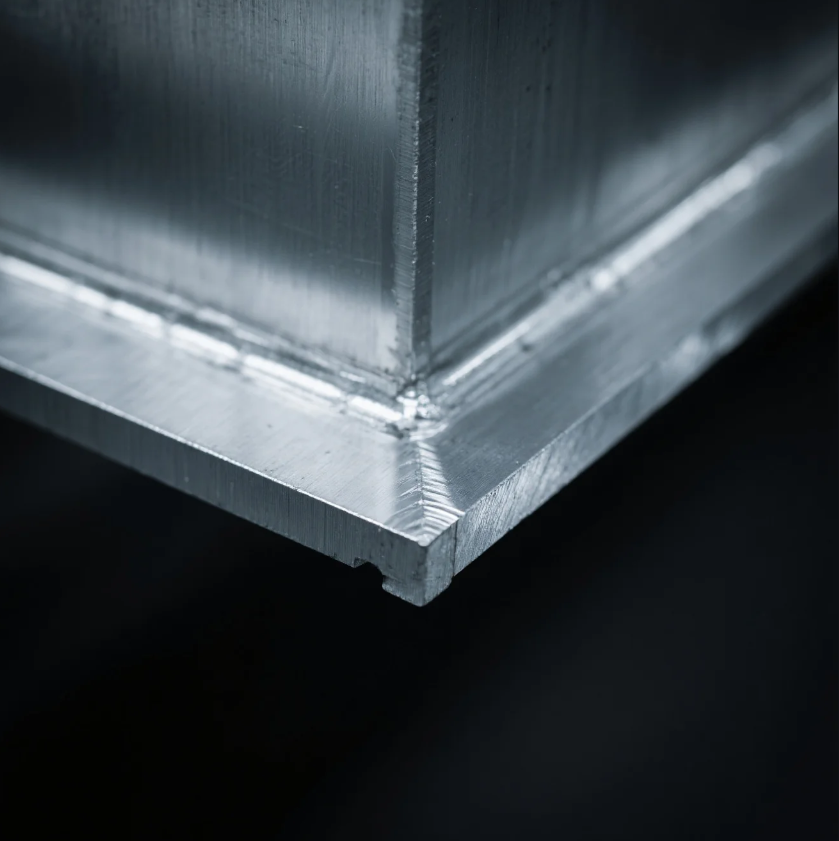

What is used to form or smooth rough metal edges?

Raw metal edges don’t just look bad—they can damage other parts during assembly.

To smooth rough edges, manufacturers use deburring tools, grinding wheels, and sometimes chemical deburring for delicate or small features.

At Prime, every ISO-certified sheet metal part goes through post-cut edge processing to ensure clean fit, safe handling, and professional appearance.

Edge Smoothing Options at Prime

| Process | Surface Result |

|---|---|

| Mechanical Grinding | Satin or matte finish |

| Vibratory Tumbling | Uniform deburred small parts |

| Edge Rounding Tool | Slight radius for safety edges |

| Surface Brushing | Visual finish for visible parts |

We help clients choose the right edge treatment based on whether the part is visible, structural, or functional.

How do I get a smooth finish on metal?

Smoothing isn’t just about safety—it’s about performance and appearance too.

To get a smooth metal finish, start with proper cutting, then apply sanding, polishing, or brushing depending on the desired texture.

At Prime, we offer finishing options including grit sanding, mirror polishing, powder coating, and anodizing—tailored to your part’s end-use.

Metal Finish Options

| Finish Type | Use Case |

|---|---|

| Brushed Finish | Decorative panels, housings |

| Matte Finish | Low-glare enclosures |

| Mirror Polish | Cosmetic stainless steel parts |

| Anodized Coating | Corrosion-resistant aluminum |

| Powder Coating | Durable, colored exterior finish |

We match finishes to function—so your part not only looks right but performs in its final environment.

Conclusion

To smooth metal corners, use the right tools and finishing process based on your part’s function and material.

Need sharp-free, smooth-edged metal parts? Prime provides precision fabrication, expert edge finishing, and full surface treatment options. Contact us today for a quote on production-ready, export-safe metal components.