How do you use a sheet metal deburring tool?

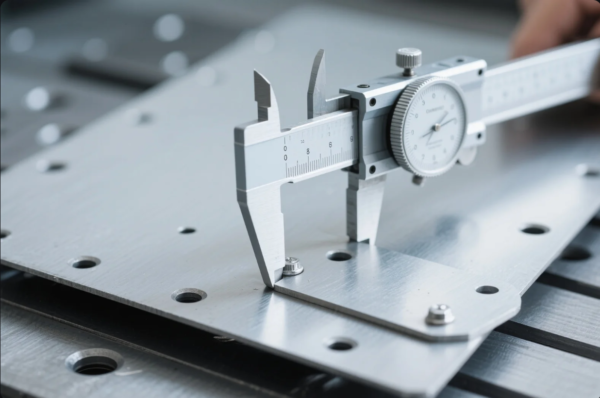

Rough edges on sheet metal are more than cosmetic—they create safety hazards and interfere with assembly.

To use a sheet metal deburring tool, glide the blade along the edge or inside holes at a 45° angle to remove burrs. Apply light, steady pressure.

At Prime, we use hand deburring tools for tight curves, holes, and post-machining cleanup, ensuring every edge meets ISO quality and safety standards.

How to deburr metal edges?

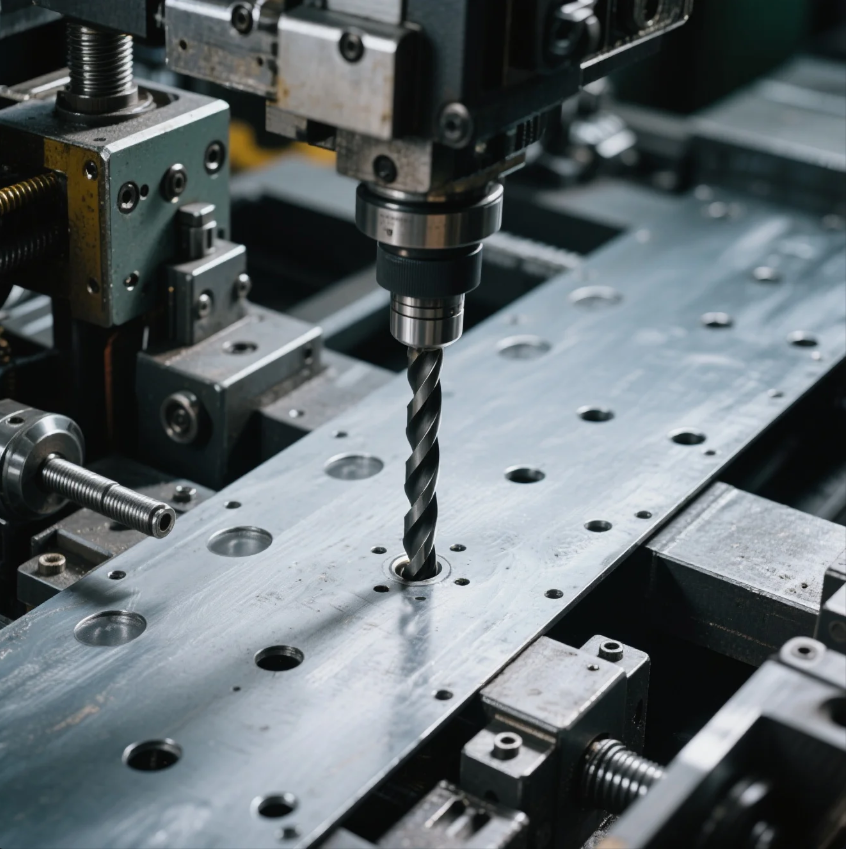

Even high-precision cuts can leave burrs that cause problems later.

You can deburr metal edges using a hand scraper, file, rotary tool, or deburring blade. Choose your method based on edge length and part volume.

At Prime, we apply edge deburring to all laser-cut, punched, or CNC-machined sheet metal parts before packaging.

Manual Deburring Steps

- Clamp the part securely on a bench.

- Hold the deburring tool with the blade facing forward.

- Drag it steadily along the edge at a 45° angle.

- Repeat as needed until smooth.

- Wipe or air-blow away debris.

This method ensures clean edges without damaging coatings or tolerances.

Is deburring easy?

Deburring might look simple—but good results require attention to detail.

Yes, basic deburring is easy with practice and the right tool. But for consistent quality, especially on curved or tight parts, it takes patience.

At Prime, we train our team to deburr efficiently using standard tools and precision jigs—ensuring consistent results across every batch.

Tips for Easier Deburring

| Tip | Result |

|---|---|

| Use fresh blades | Smoother pass, less force needed |

| Work at 45° angle | Avoids gouging or overcutting |

| Don’t rush | One clean stroke is better than many |

| Wear gloves & goggles | Safety from chips and shavings |

The smoother the cut, the easier the deburr—clean edges start with quality cutting.

How to use a hand deburring tool?

Hand deburring tools are simple—but there’s a right way to use them.

Insert the blade into the deburring handle. Hold the part firmly, then glide the blade along the edge with controlled pressure.

At Prime, we use these tools for internal holes, notches, and CNC features, especially in parts that need clean assembly or electrical contact.

Using a Hand Deburring Tool

| Step | What to Do |

|---|---|

| Step 1 | Select correct blade shape (flat, round) |

| Step 2 | Insert blade into swivel handle |

| Step 3 | Position blade at edge or hole opening |

| Step 4 | Pull smoothly along the edge |

| Step 5 | Inspect edge and repeat if needed |

Deburring inside holes? Use round-nose or “hook” blades for tight curves.

Are deburring tools supposed to swivel?

If your blade moves while cutting—don’t panic. That’s by design.

Yes, most hand deburring tools are designed to swivel. This allows the blade to follow curves and contours naturally, avoiding gouges or skips.

At Prime, we rely on swivel-blade tools for aluminum cutouts, rounded corners, and punched features where rigid tools would fail.

Benefits of Swiveling Deburring Blades

| Feature | Benefit |

|---|---|

| Blade pivots | Tracks curves smoothly |

| Auto-adjusts angle | Keeps contact with edge consistently |

| Less resistance | Requires less hand pressure |

We recommend high-carbon swivel blades for long-lasting use and clean results across stainless, aluminum, and mild steel.

Conclusion

To use a sheet metal deburring tool, hold it at a 45° angle, apply steady pressure, and let the swivel blade follow the edge smoothly.

Need metal parts with clean, burr-free edges? Prime provides precision cutting, expert edge finishing, and ISO-certified fabrication. Contact us now for a quote and professional metal part solutions you can trust.