What is the burring process in sheet metal?

Sheet metal parts often need more than cutting—they need reinforced edges too.

The burring process in sheet metal involves creating a raised edge or collar around a hole to increase strength or prepare it for fastening.

At Prime, we use burring to improve part rigidity, prevent cracking, and enhance hole durability in components that require threading, rivets, or load support.

What is the burring process?

It’s easy to confuse burring with burrs—but they serve different functions.

Burring is a metal forming process where the edge of a hole is raised or flanged, typically using a punch and die. It’s used to reinforce holes or create mounting surfaces.

At Prime, we apply burring during high-strength insert mounting or before tapping holes in thin aluminum or mild steel parts.

What Burring Looks Like

| Application | Benefit |

|---|---|

| Reinforced Mounts | Increases load-bearing capacity |

| Pre-tap Holes | Adds thread depth in thin sheet |

| Clean Hole Edging | Prevents cracking and tearing |

Burring is especially useful for lightweight parts that still require strength around fasteners.

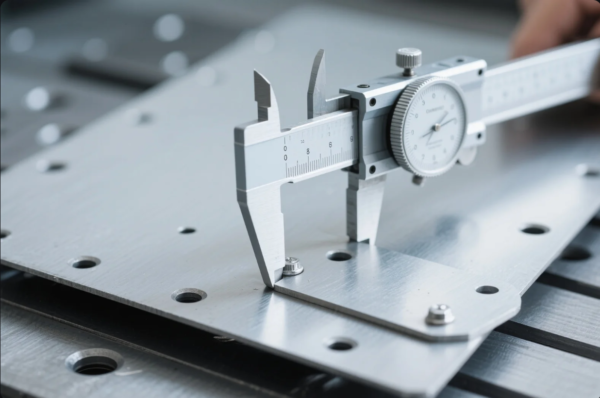

What is deburring in sheet metal?

Before finishing, every edge must be safe and smooth.

Deburring is the process of removing sharp edges, flakes, or burrs left behind after cutting, punching, or machining sheet metal.

At Prime, every punched, CNC-cut, or laser-cut part is deburred to meet ISO safety and handling standards before coating or assembly.

Deburring Methods

| Technique | Best Use Case |

|---|---|

| Manual Filing | One-off parts or tight areas |

| Rotary Deburr Tool | Holes, slots, curved edges |

| Vibratory Tumbling | Small parts in large quantities |

| Edge Rounding Machine | Uniform edge finish |

A clean edge protects both workers and the product itself during use.

What is the process of grooving sheet metal?

Grooving sounds cosmetic—but it’s all about control.

Grooving in sheet metal involves pressing a controlled channel into the sheet. It improves bend accuracy or prepares the material for folding.

At Prime, we use grooving to guide bends, reduce forming stress, and create clean fold lines in complex brackets and enclosures.

Sheet Metal Grooving Applications

| Groove Type | Purpose |

|---|---|

| Bend Line Groove | Reduces cracking during tight bends |

| Decorative Groove | Adds visual design elements |

| Drainage Groove | Allows fluid runoff in covers or trays |

We apply grooves using CNC press brakes or rotary grooving dies based on part geometry and material.

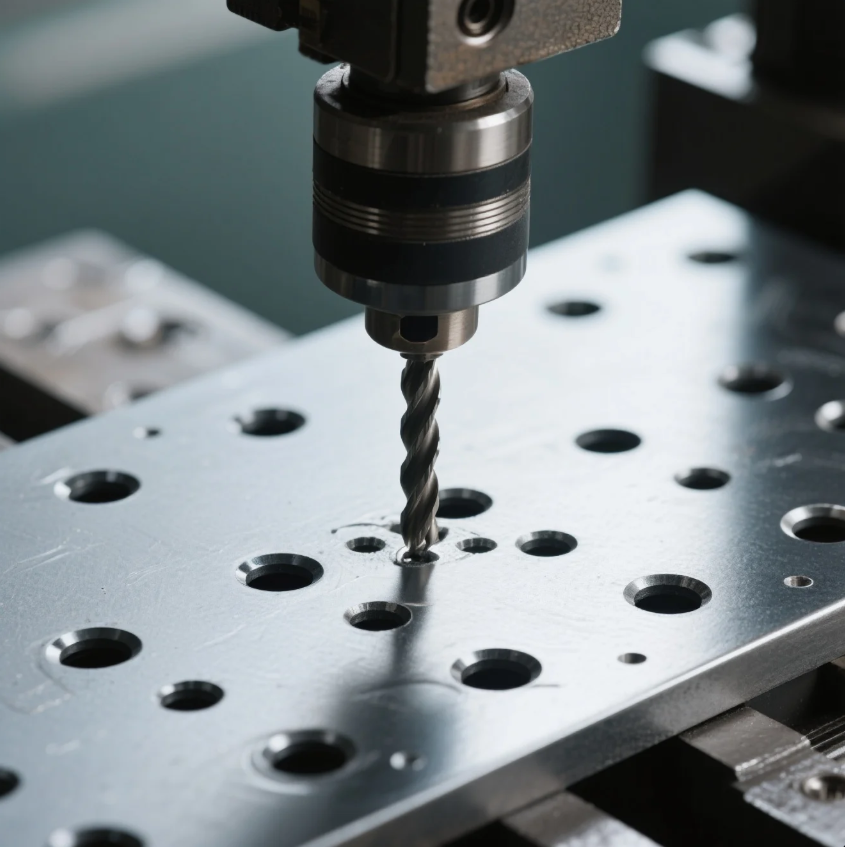

How to use a burring machine?

Using the machine correctly ensures precise results and avoids damaged parts.

To use a burring machine, align the hole under the forming punch, apply steady pressure, and raise the collar around the hole. Use proper dies for size and material.

At Prime, we use hydraulic and CNC-controlled burring machines to deliver consistent, high-strength holes across all production volumes.

Operating Steps

- Position the pre-punched hole under the tool.

- Select punch and die set for thickness/material.

- Activate the machine slowly for clean forming.

- Inspect the flange for cracks or warping.

- Repeat for all holes in batch.

Our machines are calibrated to form burrs without thinning or over-stressing the metal.

Conclusion

Burring in sheet metal strengthens hole edges by forming a raised collar—ideal for threading, riveting, or load-bearing joints.

Need burring, grooving, or edge finishing in your next project? Prime delivers precision sheet metal forming, ISO-certified burring, and expert fastener-ready hole prep. Contact us today for a quote and technical support.