How do you use snap jaws?

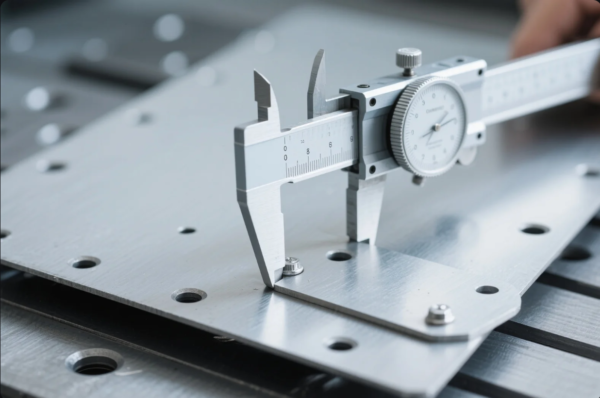

Struggling to install or remove snap fittings? You might need snap jaws—the right way.

Snap jaws are used with pliers or crimp tools to install or remove snap rings, clips, and fasteners. Choose the correct jaw size, align it with the part, and squeeze or spread as needed.

At Prime, we use snap jaws for precision assembly of sheet metal fixtures, retaining rings, and mechanical clip installations in enclosures and brackets.

How do you use jaws?

It’s all about control—grip strength without damaging the part.

To use jaws, insert them into the snap ring or clip, align the tips, and squeeze or spread based on the ring’s type—internal or external.

At Prime, we fit and remove retaining rings using snap ring pliers with interchangeable jaws to match each fastener.

Jaw Use by Application

| Snap Ring Type | Action | Jaw Motion |

|---|---|---|

| Internal | Squeeze jaws | Compress inward |

| External | Spread jaws | Expand outward |

Always use straight, 45°, or 90° jaws to access tight or angled spaces safely.

How do you use a jaw tool?

Jaw tools make fastener installs faster and more precise.

To use a jaw tool, attach the correct jaw size, insert it into the snap ring, and carefully compress or expand the ring during installation or removal.

At Prime, we use jaw tools during mechanical sub-assembly, especially for tight-fitting shaft-mounted components.

Jaw Tool Setup

- Select the right jaw tip for the fastener type.

- Insert jaws into ring holes or ends.

- Apply slow, steady pressure to compress or expand.

- Position the ring and release pressure to lock in place.

Misaligned jaws can break rings or damage the housing—precision matters.

How do you use snaps tool?

Installing snaps with your fingers? You'll want to upgrade to a snap tool.

A snaps tool presses snap fasteners (cap, socket, stud, and post) together. Align the parts, place them in the die, and apply firm, even pressure with the handle.

At Prime, we use snap tools in tool kits, protective covers, and electrical panel closures for repeatable, secure fastening.

Snap Tool Steps

| Step | Component Pair | Action |

|---|---|---|

| Cap + Socket | Top layer | Press together |

| Post + Stud | Bottom layer | Press together |

We ensure proper alignment to avoid crushing the snap or misfitting the layers.

How do you use snap clips?

Snap clips are fast, but they require careful positioning to work right.

To use snap clips, align the male and female halves, press until they snap securely, and pull apart to release. Use pliers or snap jaws for tight clips.

At Prime, we use snap clips for modular sheet metal panels, fixture mounting, and cable securing—especially in parts that require quick removal.

Snap Clip Use Cases

| Application | Benefit |

|---|---|

| Sheet metal covers | Fast access with no tools |

| Cable mounting | Keeps wires organized |

| Modular trays | Removable without screws |

Check tension—if clips are too tight, we adjust materials or spacing during DFM review.

Conclusion

Snap jaws and jaw tools allow precise control of snap rings, clips, and fasteners—making assembly safer and easier.

Need help integrating snap features or jaw-installed components into your parts? Prime offers custom sheet metal design, sub-assembly support, and fastener-ready features for high-performance industrial products. Contact us today for expert guidance and a detailed quote.