What Do You Mean by Stamping?

Are you puzzled by the term "stamping" in manufacturing? Let’s explore this technique that shapes metal with precision and efficiency.

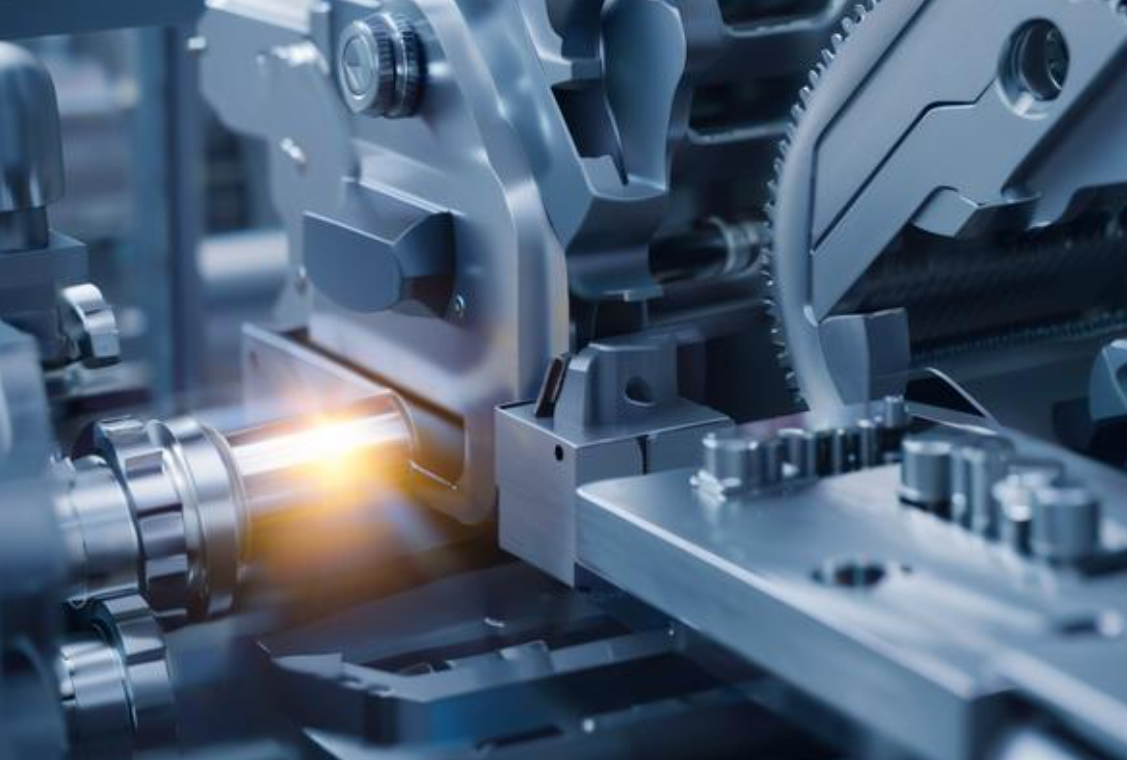

Stamping is a manufacturing process where flat metal sheets are shaped into desired forms using dies and presses, commonly used in automotive and electronics industries.

Stick around to uncover the intricate details of stamping and how it can benefit your industrial needs.

What is Metal Stamping?

Ever wondered how intricate metal parts are made? Metal stamping transforms flat metal sheets into precise shapes.

Metal stamping involves using dies and presses in a controlled environment to shape metal into components, often used in high-volume production.

The Stamping Process

Metal stamping is a multi-step process requiring precision and expertise. It begins with designing the part, followed by creating the die and finally stamping the metal. Here’s a brief breakdown:

- Design: Engineers create detailed blueprints of the part.

- Die Creation: A die, essentially a specialized mold, is crafted based on the design.

- Stamping: The metal sheet is placed into the press, and the die shapes it into the required component.

Types of Stamping

There are various types of stamping techniques, each suited for different applications:

| Type | Description |

|---|---|

| Progressive Stamping | Multiple operations in a single press stroke |

| Blanking | Cutting out flat shapes from metal sheets |

| Bending | Forming metal into angles or curves |

Applications of Metal Stamping

Metal stamping is widely used across various industries due to its versatility and efficiency. Common applications include automotive parts, electronic components, and consumer goods. It’s particularly valued in industries requiring high precision and repeatability.

Why Choose Stamping for Manufacturing?

Why should you consider stamping for your manufacturing needs? It offers several advantages.

Stamping provides high precision, repeatability, and cost-effectiveness, making it ideal for mass production of metal parts.

Advantages of Stamping

Metal stamping isn’t just about shaping metal; it’s about efficiency and quality. Key benefits include:

- High Precision: Stamping ensures intricate details and consistent quality.

- Cost-Effective: Reduces material waste and labor costs.

- Scalability: Perfect for large production runs.

Material Considerations

Choosing the right material is crucial for successful stamping. Common materials include:

| Material | Characteristics |

|---|---|

| Steel | Durable and cost-effective |

| Aluminum | Lightweight and corrosion-resistant |

| Copper | Excellent electrical conductivity |

Challenges in Stamping

Like any manufacturing process, stamping has its challenges. Material selection, die maintenance, and press calibration are critical factors to consider. Addressing these challenges requires expertise and careful planning.

What Industries Rely on Stamping?

Which industries depend heavily on stamping for their operations? Many do!

Stamping is crucial in the automotive, electronics, and aerospace industries for producing complex, high-quality parts efficiently.

Automotive Industry

In the automotive sector, stamping is used to create body panels, chassis components, and engine parts. Its ability to produce high-strength, lightweight parts makes it indispensable.

Case Study: Automotive Panels

Automotive manufacturers rely on stamping for producing intricate body panels. This process ensures durability and aesthetic appeal, meeting strict industry standards.

Electronics Industry

In electronics, stamping creates components like connectors, terminals, and shields. Precision and repeatability are critical in this field.

Aerospace Industry

The aerospace industry demands high-strength, lightweight components that can withstand extreme conditions. Stamping meets these stringent requirements, ensuring safety and performance.

How Does Prime Utilize Stamping?

How does Prime leverage stamping to meet client needs? By combining expertise with advanced technology.

Prime employs state-of-the-art stamping techniques to deliver high-quality, customizable parts, ensuring client satisfaction and industry leadership.

Custom Solutions at Prime

At Prime, we understand that each client has unique requirements. Our team works closely with clients to develop custom stamping solutions tailored to their specific needs.

Quality Assurance

Quality is our top priority. We adhere to ISO standards and rigorous quality control checks throughout the production process, guaranteeing superior products.

Commitment to Innovation

Prime is committed to staying at the forefront of manufacturing technology. We continuously invest in new equipment and techniques to enhance our stamping capabilities, ensuring we meet the evolving demands of our clients.

Conclusion

Stamping is a precise, efficient manufacturing process essential for various industries. Prime excels in delivering high-quality, customizable stamping solutions.