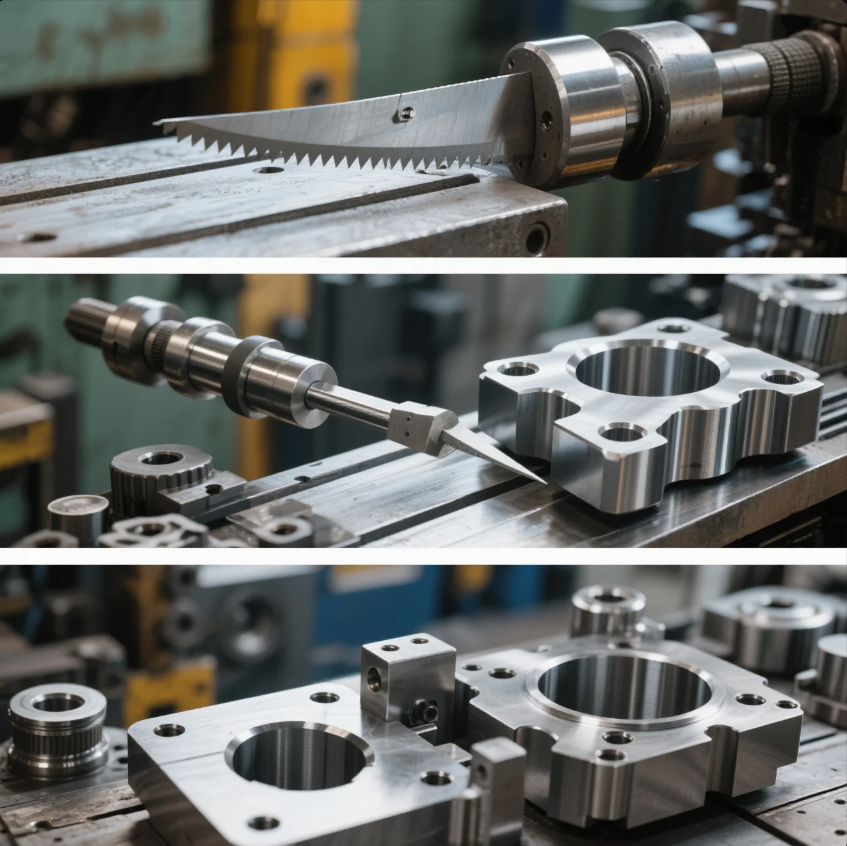

What is a big problem with 3D printed parts?

Image: A failed 3D printed bracket due to thermal distortion and insufficient layer bonding.

Engineer (Prime): Let’s talk honestly—what is a big problem with 3D printed parts?

Buyer: I’ve been wondering the same. We’re looking into metal additive manufacturing, but I’ve heard the failure rate is high. What should we watch out for?

Engineer: You're right to ask. 3D printing offers design freedom, but also introduces challenges. And yes, one big problem with 3D printed parts is inconsistency—things like internal porosity, weak adhesion, and geometry distortion.

Table of Contents

- What is the biggest problem with 3D printing?

- What is the biggest disadvantage of 3D printing?

- What are the disadvantages of 3D printing body parts?

- What is the most common 3D print fail?

- Frequently Asked Questions (FAQ)

- Conclusion

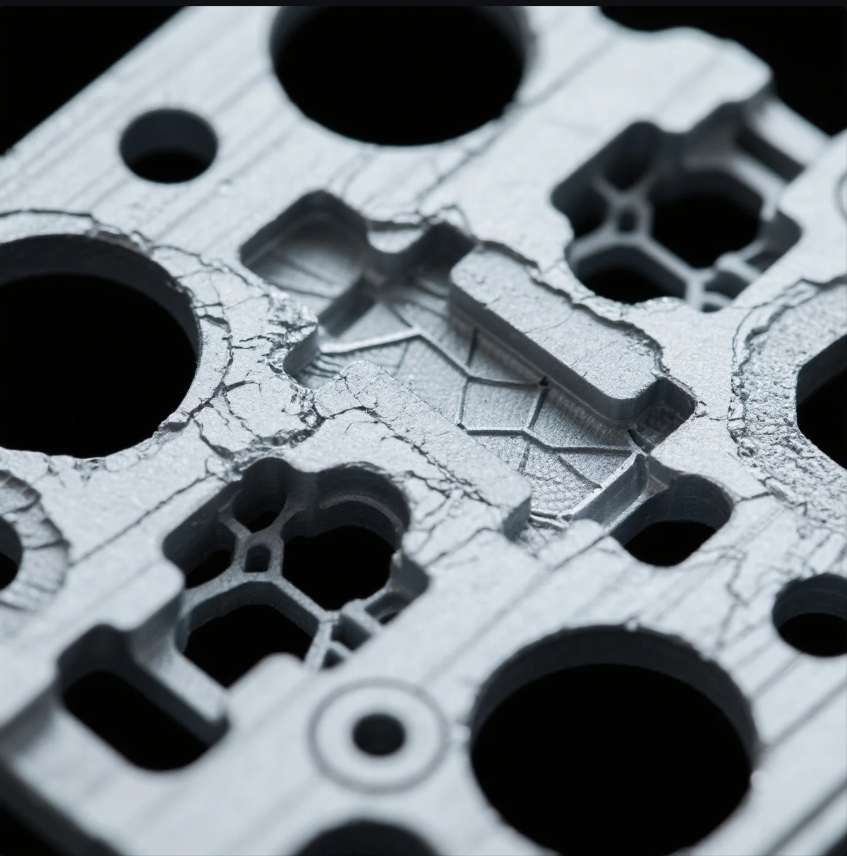

What is the biggest problem with 3D printing?

Image: A scan revealing porosity in a 3D printed titanium part.

Buyer: So, what is a big problem with 3D printed parts when it comes to critical performance?

Engineer: The top issue is internal inconsistency. You can’t always see it—but it can ruin a part’s integrity. For example:

- Tiny voids form during layer fusion

- Incomplete sintering weakens the core

- Thermal stress causes warping or cracking

Buyer: Can you detect those issues?

Engineer: At Prime, we use CT scanning and destructive testing to spot these flaws before shipment. But for many companies, they go unnoticed until the part fails in use.

Summary:

In short, a big problem with 3D printed parts is you don’t always know they’re defective—until it's too late.

What is the biggest disadvantage of 3D printing?

Image: A support-heavy part requiring manual finishing after DMLS printing.

Buyer: Aside from hidden defects, what else limits 3D printing for us?

Engineer: The biggest disadvantage? Post-processing.

Even a perfect print still needs:

- Support removal

- Heat treatment

- Machining to meet tolerance

- Surface smoothing or anodizing

These steps add time, labor, and cost. So for volume runs, casting or CNC is often more scalable.

Buyer: Makes sense. Design freedom comes at a cost.

Summary:

Yes—and that's why we help clients balance 3D printing with other processes.

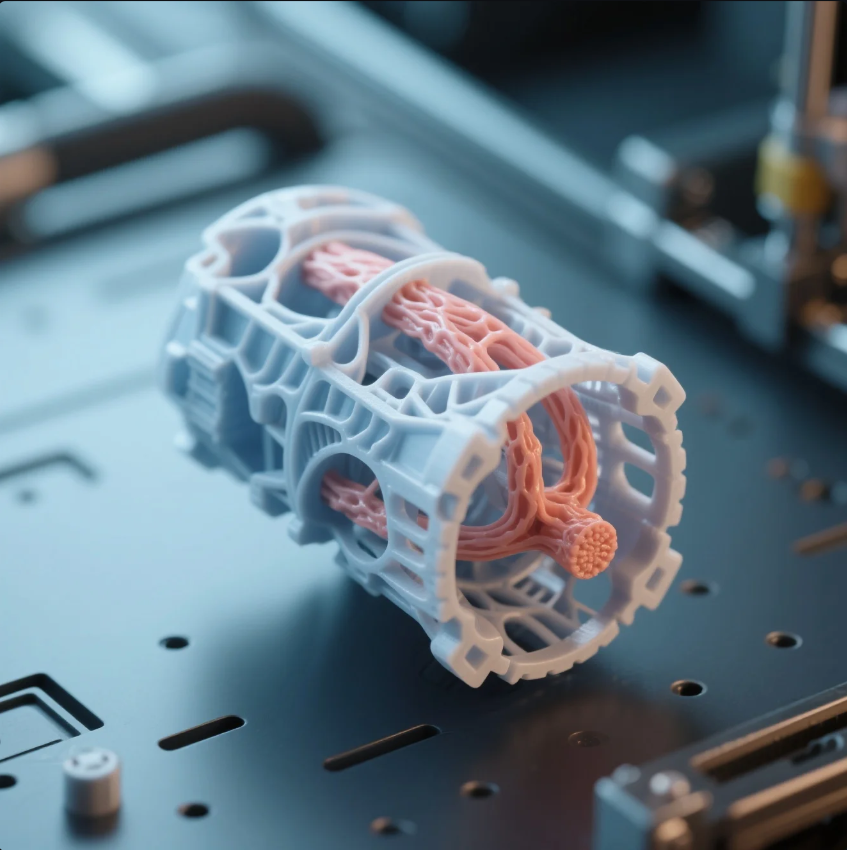

What are the disadvantages of 3D printing body parts?

Image: A non-invasive device casing printed for a medical startup.

Buyer: What about medical parts? Isn’t 3D printing a big deal in healthcare?

Engineer: It is—but not without risks.

- Materials may not be biocompatible

- Certification takes years

- Mechanical strength must meet strict thresholds

- Long-term behavior inside the body is uncertain

At Prime, we don’t do implants, but we do support medical-grade device enclosures and tool prototypes under NDA.

Summary:

Medical 3D printing is promising, but it’s limited by safety, regulation, and material science.

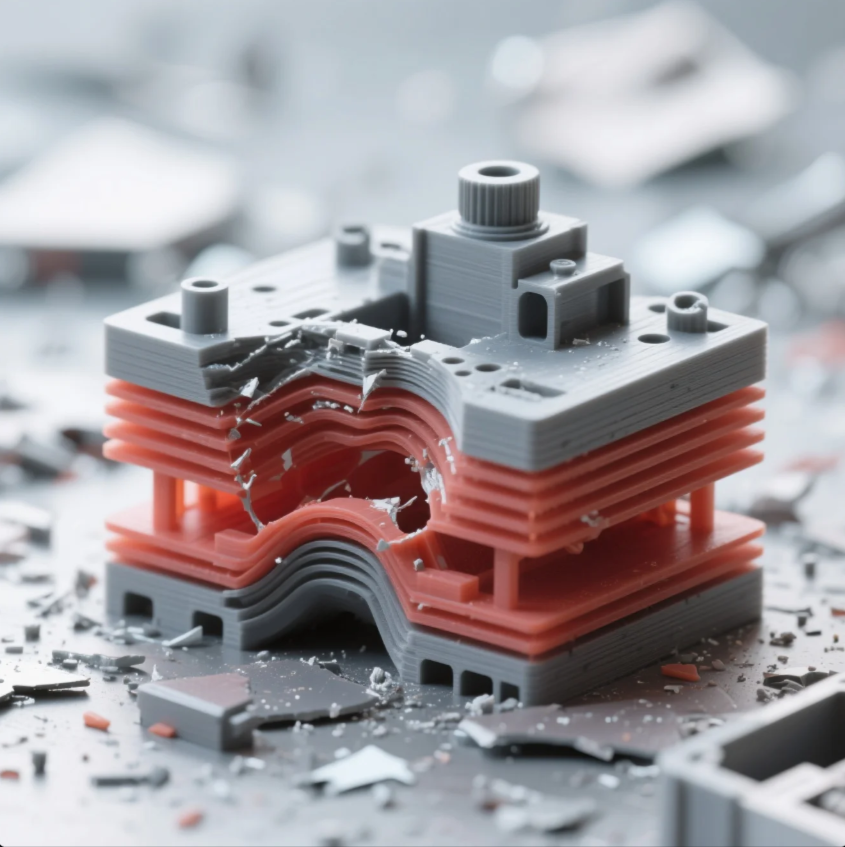

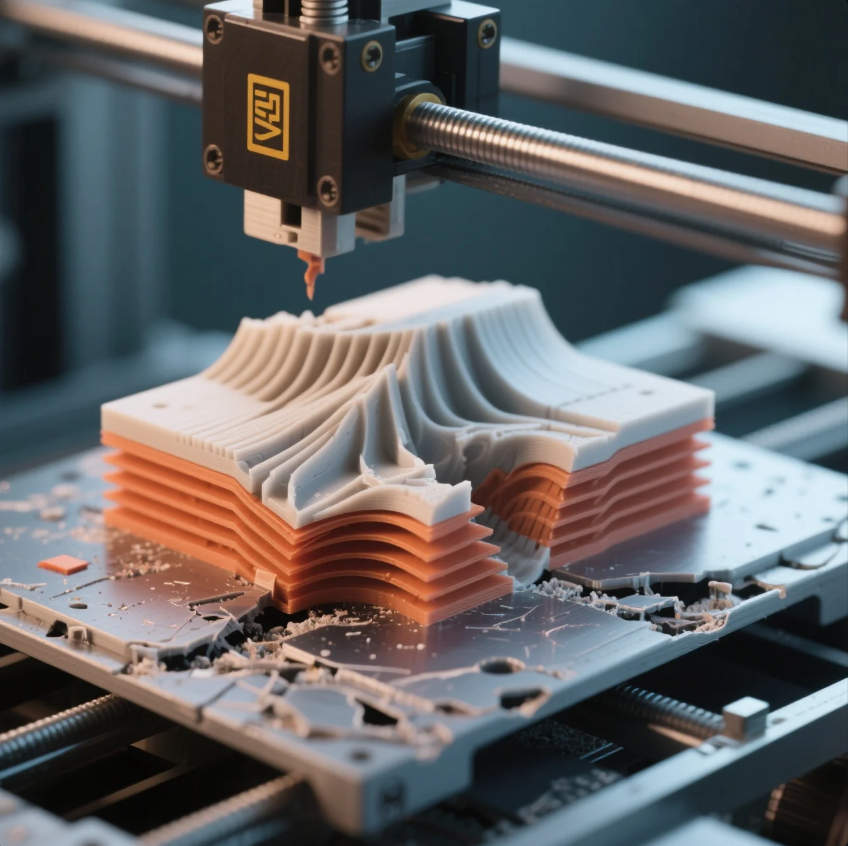

What is the most common 3D print fail?

Image: A warped print with poor bed adhesion and layer splitting.

Buyer: One last thing—what’s the most common failure?

Engineer: Warping and delamination, by far.

These usually result from:

- Wrong temperature or print speed

- Inadequate bed leveling

- Lack of internal supports

- Overhangs not properly scaffolded

Buyer: So, again—it’s all about consistency.

Engineer: Exactly. That’s why what is a big problem with 3D printed parts always comes down to quality control.

Frequently Asked Questions (FAQ)

❓ Can I repair a failed print?

Engineer: Minor surface issues, yes. Internal problems? Usually not—reprint is safer.

❓ What’s the fix for porosity?

Engineer: Heat treatment helps, but CT inspection is the first step. Prime offers both.

❓ Is metal printing more reliable than plastic?

Engineer: Not really. It’s stronger, but harder to control and costlier to fix.

❓ Should I avoid 3D printing?

Engineer: Avoid it if:

- You need tight tolerances

- You make >500 pcs

- The part must be flawless cosmetically

Conclusion

Buyer: So, what is a big problem with 3D printed parts? It’s unpredictability—from porosity to post-processing costs.

Engineer: Exactly. That’s why at Prime, we combine additive expertise with casting, stamping, and CNC—to ensure you always get the right part, the right way.

Ready to test 3D printing or switch to a more stable method?

Contact Prime for a free design review, CT scan consultation, or multi-process comparison.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com