How much does it cost to fabricate metal parts?

Buyer: I’m planning a new product and need a sense—how much does it cost to fabricate metal parts?

Engineer (Prime): Great question. The cost of fabricating metal parts depends on many factors: material, complexity, quantity, and processes involved. Let’s walk through typical pricing models, cost drivers, and what you can expect.

Table of Contents

- How much to charge for metal fabrication?

- What is the fabrication process cost?

- What is the profit margin for metal fabrication?

- What are fabrication charges?

- Frequently Asked Questions (FAQ)

- Conclusion

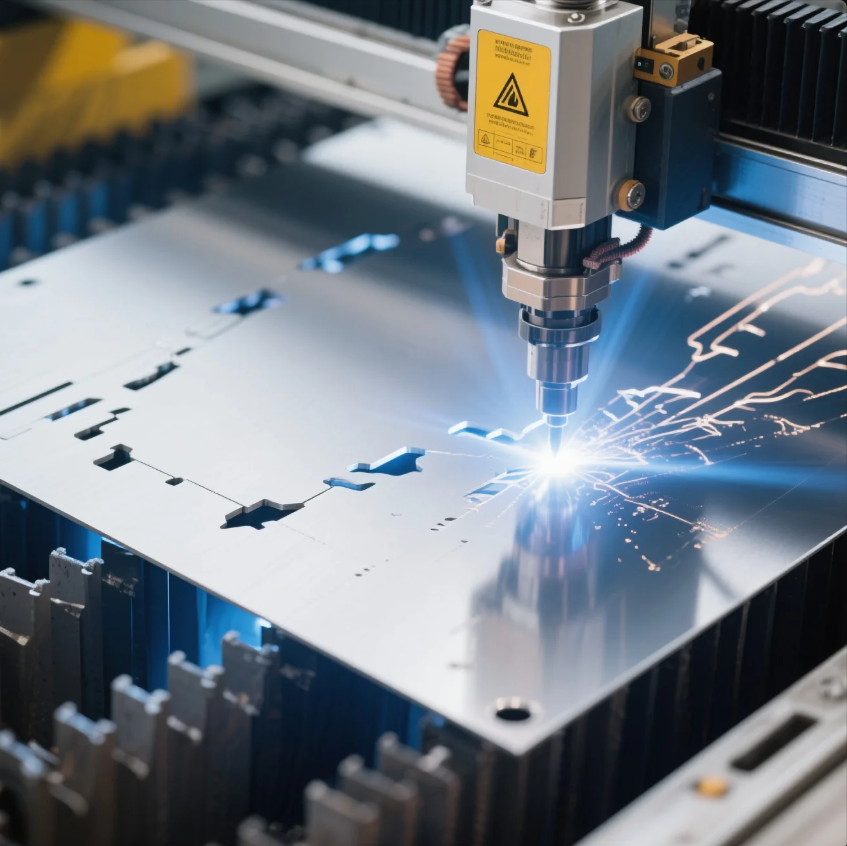

How much to charge for metal fabrication?

Buyer: Let’s say I’m ordering a batch of metal brackets—how’s the pricing usually structured?

Engineer: Metal fabrication pricing usually includes:

- Raw material cost (steel, aluminum, etc.)

- Setup + machine time (CNC, laser, welding, etc.)

- Labor for finishing, inspection, packaging

- Markup or margin

| Process | Typical Hourly Rate (USD) |

|---|---|

| Laser cutting | \$65–\$100/hour |

| CNC machining | \$75–\$150/hour |

| Welding | \$50–\$85/hour |

| Finishing/polishing | \$30–\$60/hour |

For small batches, expect \$5–\$25 per part for simple jobs, and \$50+ per part for custom or tight-tolerance work.

Buyer: So there’s a setup fee plus cost-per-part?

Engineer: Exactly. That’s why we help clients at Prime optimize part geometry for lower machine time and scrap.

What is the fabrication process cost?

Buyer: What makes one part more expensive than another?

Engineer: Main cost drivers include:

- Material type – Stainless steel or titanium costs more than mild steel

- Thickness & tolerance – Thicker parts need slower cuts or multi-step finishing

- Number of operations – Cutting + bending + welding increases labor and handling

- Volume – One-off parts are expensive; batch runs get lower per-unit rates

At Prime, we estimate fabrication cost using BOM analysis + process simulation.

Summary: The more complex and low-volume the part, the higher the per-unit fabrication cost.

What is the profit margin for metal fabrication?

Buyer: What’s a typical markup or margin for metal fabricators?

Engineer: In B2B fabrication, average gross profit margins range between 20–40%, depending on:

- Material price volatility

- Overhead costs (facility, tooling, inspection)

- Required certifications (ISO, PPAP, etc.)

- Volume and repeatability

Prime focuses on long-term client relationships, so we offer transparent quotes with optional cost-saving recommendations.

| Cost Component | % of Final Price |

|---|---|

| Raw Material | 30–50% |

| Machine Time | 20–35% |

| Labor & Finishing | 15–25% |

| Overhead + Margin | 10–20% |

Buyer: So markup isn’t just profit—it includes hidden costs?

Engineer: Exactly. We document all steps clearly, so buyers know what they’re paying for.

What are fabrication charges?

Buyer: I’ve seen the term “fabrication charge” on quotes. What does it include?

Engineer: A fabrication charge usually covers all the custom work involved, including:

- Machine setup

- Tooling wear

- CAD or CAM programming

- Quality control checks

- Handling and packaging

This is usually applied as a flat fee per order, or blended into per-part pricing for larger runs.

Buyer: So even if the part seems simple, the setup might still cost a bit?

Engineer: Correct. Especially for one-time or small-batch parts. But at Prime, we waive or reduce setup charges for ongoing orders.

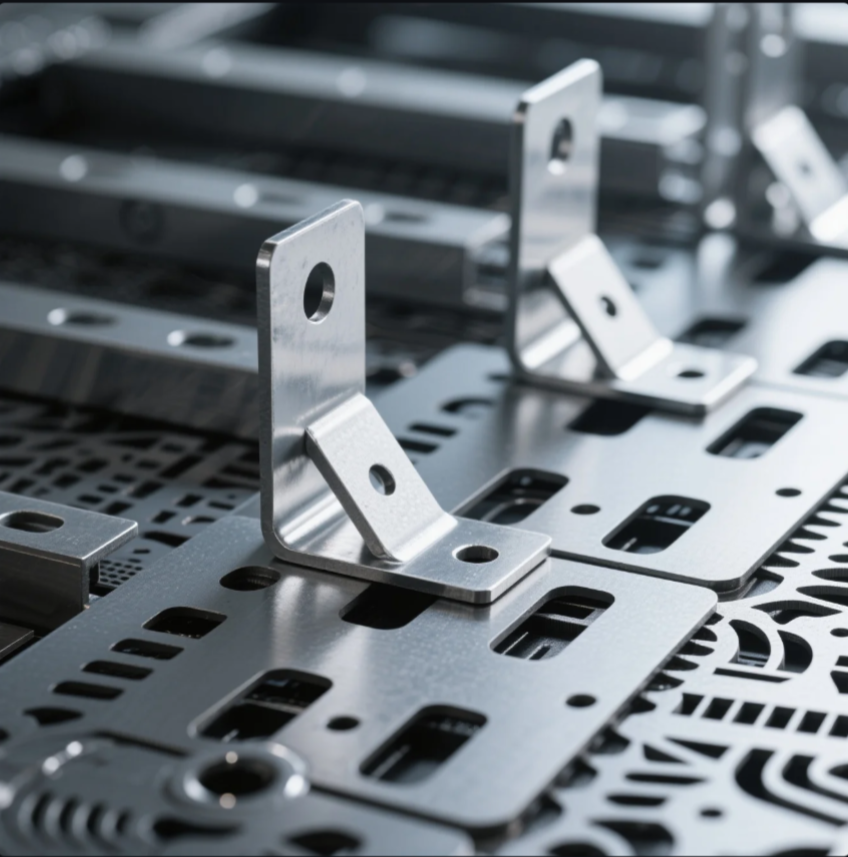

Frequently Asked Questions (FAQ)

❓ How can I reduce metal fabrication cost?

Engineer: Simplify the geometry, increase batch size, and use standard materials or finishes.

❓ What’s cheaper—CNC or laser cutting?

Engineer: For flat parts, laser is faster and cheaper. For complex 3D profiles, CNC is better.

❓ Do you offer volume discounts?

Engineer: Yes. At Prime, we offer scaled pricing for orders above 100, 500, and 1000 units.

❓ What materials do you work with?

Engineer: Carbon steel, stainless, aluminum, brass, copper, titanium, and more. All ISO-certified.

Conclusion

Buyer: So, how much does it cost to fabricate metal parts?

Engineer: Anywhere from a few dollars to hundreds—depending on material, process, volume, and complexity. But we help clients design smarter parts to hit both budget and performance goals.

Buyer: I’ll send you my drawings for review.

Engineer: Great! We’ll provide a quote, lead time, and manufacturing suggestions.

Need accurate metal part pricing with clear breakdowns and ISO-certified quality?

Contact Prime for a free consultation, DFM feedback, and fast quote.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com