Is steel stronger in compression or tension?

Buyer: I’m working on a support frame design. I keep wondering—Is steel stronger in compression or tension?

Engineer (Prime): That’s a classic materials question! Steel performs well in both—but technically, steel is slightly stronger in tension than in compression, especially in structural applications where buckling matters. Let’s unpack what that really means.

Table of Contents

- Is steel stronger in tension or compression?

- Does steel fail in tension or compression?

- Is steel equally strong in tension and compression?

- Is rebar stronger at compression or tension?

- Frequently Asked Questions (FAQ)

- Conclusion

Is steel stronger in tension or compression?

Buyer: So, what’s the short answer?

Engineer: Steel has nearly equal tensile and compressive strength when looking at raw material properties (like yield strength), but real-world structures often fail in compression first—not because steel is weaker, but because of buckling.

| Load Type | Raw Strength (MPa) | Real-World Weakness |

|---|---|---|

| Tension | \~350–550 MPa | Necking, fracture |

| Compression | \~350–550 MPa | Buckling, lateral instability |

So yes, steel resists tension better in practice, especially in long, slender parts.

Does steel fail in tension or compression?

Buyer: Which failure mode happens more often?

Engineer: It depends on the shape:

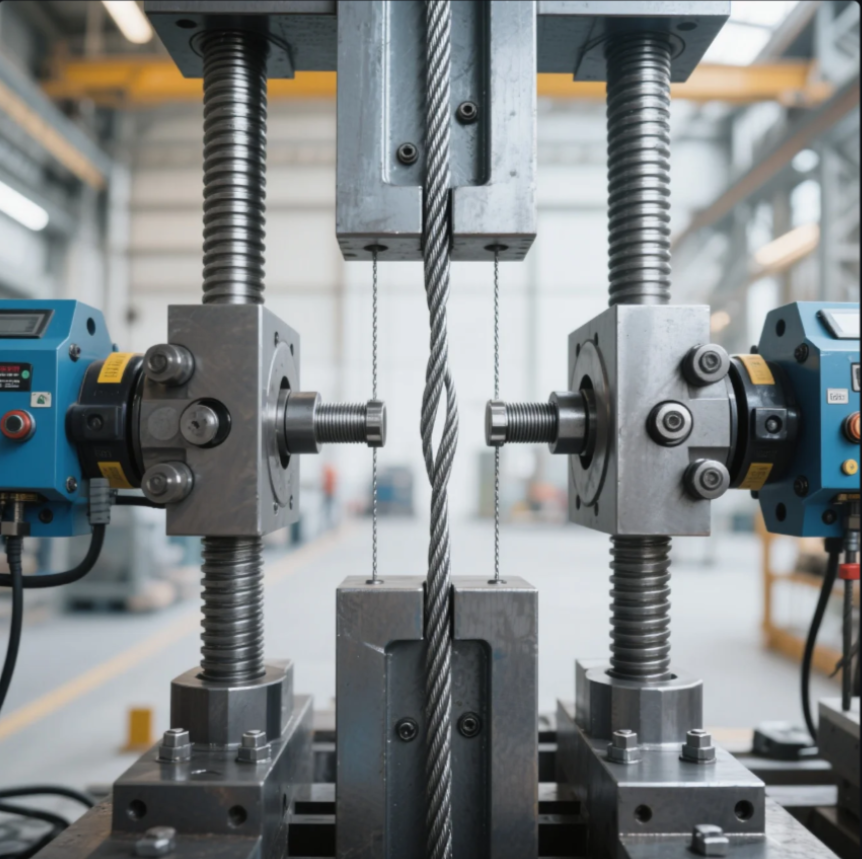

- In tension, steel stretches until it yields and eventually breaks

- In compression, it buckles if the member is long or slender

Compression failure usually happens at lower loads due to shape instability—even though the material strength is the same.

At Prime, we always review part geometry to avoid unintended failure modes.

Summary: Compression often causes structural failure first—due to geometry, not weaker steel.

Is steel equally strong in tension and compression?

Buyer: Are tensile and compressive values ever truly equal?

Engineer: For most structural steels like ASTM A36 or 1018:

- Yield strength in tension = \~250 MPa

- Yield strength in compression = \~250 MPa

So yes—on paper, they’re equal. But in design, compression strength is limited by geometry (Euler’s buckling equation).

Designers use safety factors and cross-sectional shapes to reduce the risk of compressive failure.

Summary: Material strength is equal, but effective strength in compression depends on part shape.

Is rebar stronger at compression or tension?

Buyer: What about rebar in concrete—why is it always used for tension?

Engineer: Good catch. Concrete handles compression well, but cracks under tension. That’s why rebar (usually high-strength carbon steel) is placed in tension zones of beams or slabs.

Rebar:

- Tensile strength = \~500 MPa

- In compression, it can buckle if unsupported

That’s why in columns, spirals or ties support rebars against buckling.

Summary: Rebar is strongest in tension—and that’s how it’s typically used in structural applications.

Frequently Asked Questions (FAQ)

❓ Why does compression fail faster in long beams?

Engineer: Because of buckling, which depends on length, cross-section, and end support.

❓ Does the material itself change strength in compression?

Engineer: No. For isotropic metals like steel, tensile and compressive yield strength are nearly equal.

❓ What’s the best steel for compression loads?

Engineer: Use higher-strength structural steels (like 1045 or 4140) and optimize geometry (box sections, tubes).

❓ How can Prime help me choose the right material?

Engineer: We review your part's load case, geometry, and production method, then recommend the ideal steel type or shape.

Conclusion

Buyer: So, is steel stronger in compression or tension?

Engineer: On paper—equal. But in real designs, steel performs better in tension because compression is limited by buckling. At Prime, we help clients avoid failure by optimizing both material and part geometry.

Buyer: That makes sense. I’ll revise my design to use a square tube instead of flat bar for the vertical support.

Engineer: Smart move. Send us your files—we’ll run a stress and buckling check and quote the best-fit material.

Need help optimizing your part for tension or compression loads?

Contact Prime for free design feedback, material advice, and ISO-certified metal part production.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com