What Is the Best Metal to Not Scratch?

When surface appearance matters, scratch resistance becomes a key factor.

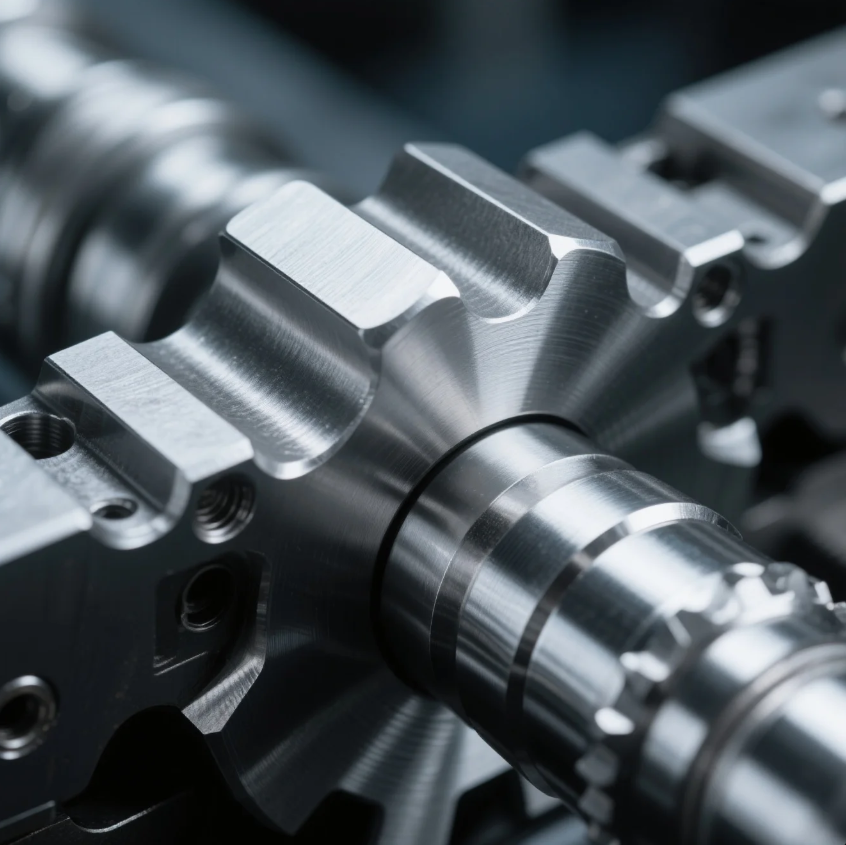

The best metals for resisting scratches are titanium, stainless steel, and tungsten. Each offers different benefits depending on use.

In this guide, we’ll compare top anti-scratch metals, their applications, and how to choose the right one for your needs.

Table of Contents

- Which Metal Is Most Scratch Resistant?

- What Is the Best Anti Scratch Metal?

- What Is the Best Metal for Not Scratching?

- What Metal Can't Be Scratched?

- FAQs

- Contact Prime

Which Metal Is Most Scratch Resistant?

When clients need surface durability, hardness becomes the key metric.

Tungsten and titanium rank among the hardest, most scratch-resistant metals used in industrial and consumer products.

Scratch Resistance Rankings by Vickers Hardness

| Metal | Vickers Hardness | Scratch Resistance | Common Uses |

|---|---|---|---|

| Tungsten | 3430 HV | Extremely High | Aerospace, wear parts |

| Titanium | 830–1000 HV | Very High | Medical, sports gear |

| Stainless 440C | 600–650 HV | High | Bearings, knives |

| Aluminum | 167 HV | Low | Prototypes, enclosures |

Tungsten is rarely scratched, even in harsh conditions. But it’s brittle and heavy, so not ideal for all uses. For balance, many clients choose stainless or titanium with a brushed or coated surface.

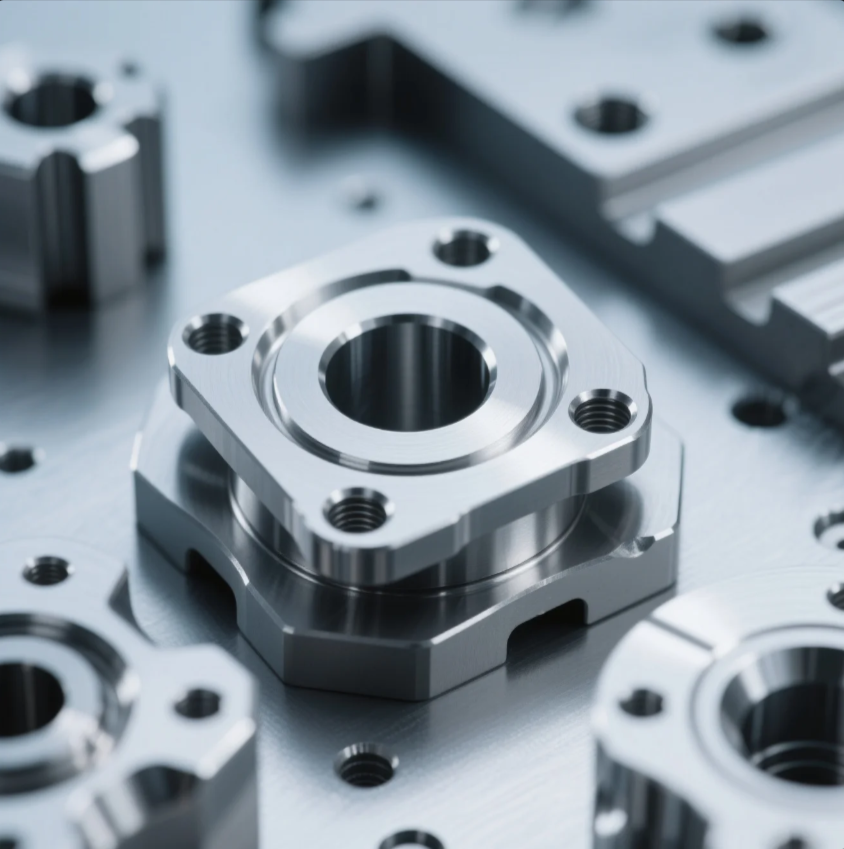

What Is the Best Anti Scratch Metal?

The “best” depends on your needs: visual finish, strength, or machining ease.

For structural parts: stainless steel. For high-end or wearable products: titanium.

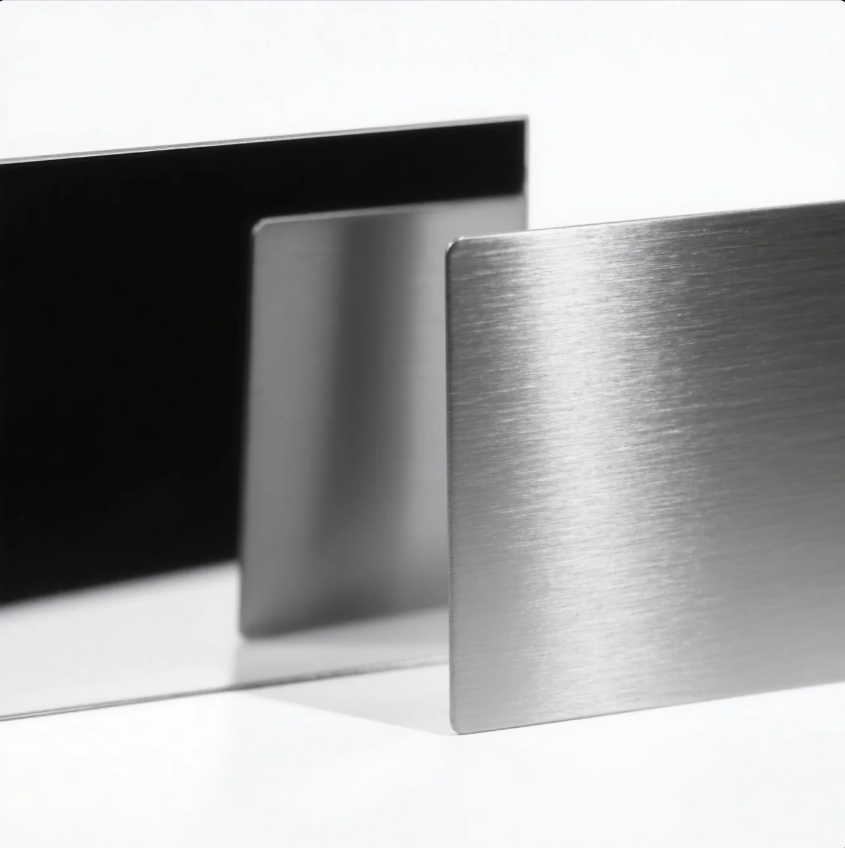

How Surface Treatment Affects Scratch Resistance

Even softer metals can improve performance with coatings:

| Method | Benefit | Metals Commonly Treated |

|---|---|---|

| Anodizing | Adds a protective layer | Aluminum, titanium |

| PVD Coating | Ceramic-hard surface | Stainless, titanium, brass |

| Brushed Finishing | Hides light scratches | Stainless steel, aluminum |

| Powder Coating | Surface hardening + color | Steel, aluminum |

At Prime, we apply finishes that enhance durability and aesthetics. We support brushed stainless, anodized aluminum, and PVD-coated titanium parts — for clients in electronics, medical, and consumer products.

What Is the Best Metal for Not Scratching?

Choosing a metal that resists damage keeps your product looking new — longer.

Titanium offers one of the best scratch resistance-to-weight ratios, while stainless balances hardness and cost.

Ideal Uses for Anti-Scratch Metals

| Application | Best Metal | Reason |

|---|---|---|

| Medical Devices | Titanium | Lightweight, biocompatible, durable |

| Electronics Housing | Brushed stainless | Resists wear, maintains clean look |

| Watches & Jewelry | Tungsten, titanium | High wear resistance, premium appearance |

| Industrial Bearings | 440C Stainless Steel | High hardness, corrosion resistant |

We guide clients through material selection for custom CNC parts, based on where the part will be used and what kind of wear it will face.

What Metal Can't Be Scratched?

No metal is 100% scratch-proof, but some are close.

Tungsten carbide is so hard it can scratch most other materials — yet won’t scratch easily itself.

Why Tungsten Carbide Is Nearly Unscratchable

- Vickers hardness of over 2000–3000

- Extremely dense, wear-resistant

- Often used in mining, machining, or extreme environments

Drawback? It's brittle. So we recommend it only when:

- The part won’t face sudden shocks

- Extreme wear resistance is a must

Most of our clients choose 440C stainless steel or titanium for everyday anti-scratch applications — balancing durability, weight, and cost.

FAQs

Q1: Can aluminum be made scratch resistant?

Yes. Anodizing increases surface hardness. Still, it’s not as tough as stainless or titanium.

Q2: What’s better — PVD coating or anodizing?

PVD is harder and used on stainless/titanium. Anodizing is for aluminum.

Q3: Can Prime provide brushed or matte finishes?

Yes. We offer brushed, polished, matte, and coated finishes on multiple metals.

Q4: What’s the most cost-effective anti-scratch option?

Brushed 304 or 316 stainless steel — durable, affordable, and easy to fabricate.

Q5: Do you offer laser engraving on hard metals?

Yes. We can engrave on stainless, titanium, and even coated surfaces.

Contact Prime

Want expert help choosing the right metal for your wear-resistant parts?

📞 Get a quote now — with full material advice and surface options:

👉 Visit: https://primecustomparts.com

📧 Email: [email protected]

With Prime, your parts don’t just perform — they stay sharp and scratch-free.