What Is Meant by Metal Fabrication?

Whether you're an engineer, buyer, or DIY maker — understanding fabrication is key to sourcing the right parts.

Metal fabrication refers to the process of creating metal structures or components by cutting, bending, welding, and assembling raw materials into finished products.

In this guide, we’ll explain what fabrication means, share real-world examples, and clear up common misunderstandings.

Table of Contents

- What Are Examples of Metal Fabrication?

- What Are the Three Types of Metal Fabrication?

- What Does a Metal Fabricator Do?

- Is Metal Fabrication the Same as Welding?

- FAQs

- Contact Prime

What Are Examples of Metal Fabrication?

Fabrication is all around us — from household items to complex industrial parts.

Common examples include brackets, enclosures, frames, control cabinets, machine parts, and structural supports.

Real-World Fabrication Examples

| Product Type | Material Used | Industry Application |

|---|---|---|

| Electrical enclosures | Sheet metal | Control panels, telecom |

| Mounting brackets | Stainless steel | Furniture, electronics |

| Welded frames | Mild steel | Industrial equipment |

| Air duct connectors | Galvanized sheet | HVAC systems |

| Medical trays | Stainless steel | Hospitals, clinics |

At Prime, we produce all of the above and more — using CNC, welding, stamping, and coating processes.

What Are the Three Types of Metal Fabrication?

Fabrication uses three core processes — everything else builds from them.

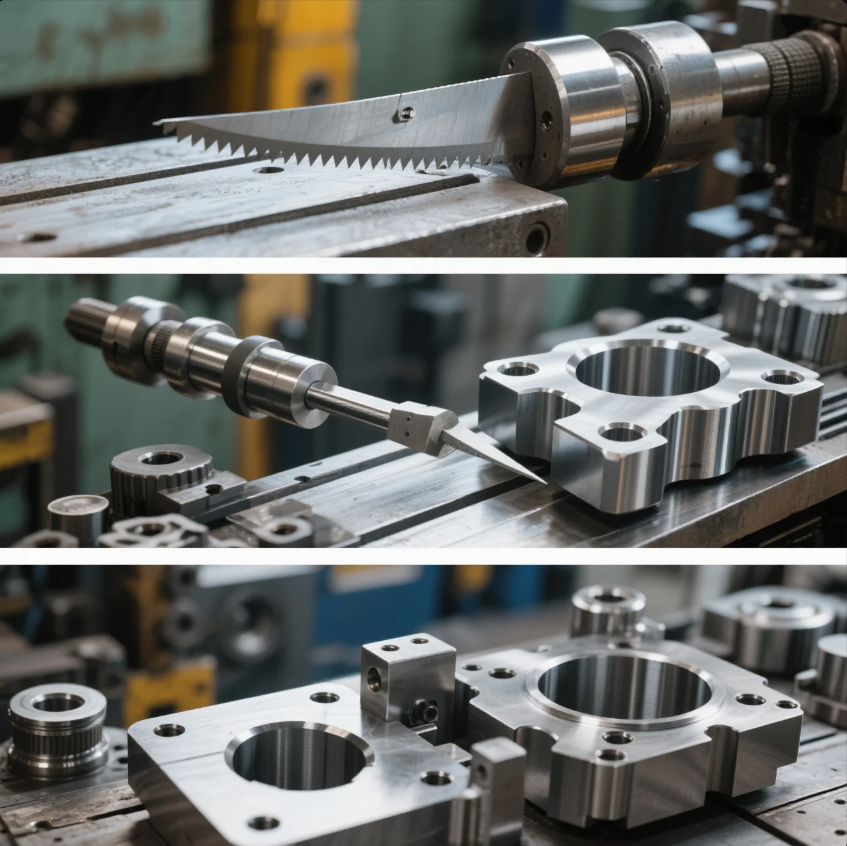

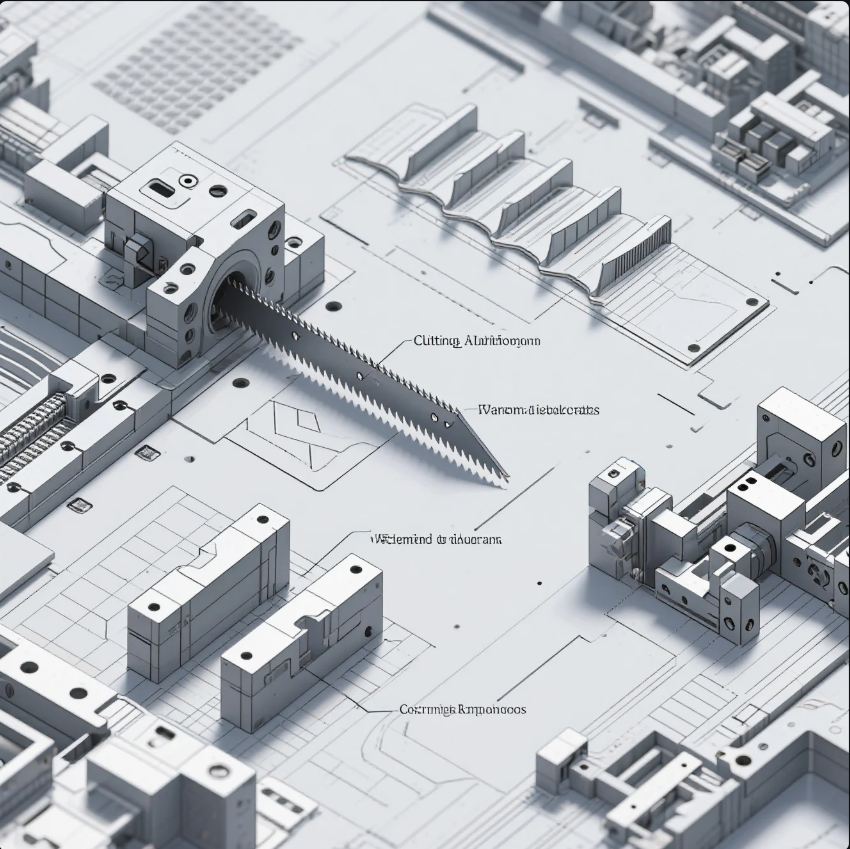

The three types of fabrication are cutting, forming, and assembly.

Overview of Core Methods

| Type | Function | Equipment Used |

|---|---|---|

| Cutting | Defines shape, holes, edges | Laser, plasma, waterjet, saws |

| Forming | Changes shape without cutting | Press brake, rollers, hammers |

| Assembly | Joins parts into one component | MIG/TIG welding, rivets, bolts |

Some projects use all three, while others focus on just one — like cutting aluminum plates or welding steel tubes into a frame.

What Does a Metal Fabricator Do?

Fabricators turn raw metal into finished parts based on blueprints or specs.

A metal fabricator operates tools to cut, shape, and assemble metal materials into usable products or components.

Typical Fabricator Responsibilities

- Interpret technical drawings or CAD files

- Set up machines for cutting and forming

- Weld or fasten parts together

- Check finished parts for tolerance and finish

- Package components for delivery or installation

At Prime, our fabricators work closely with engineers and QC teams to ensure every order meets international standards.

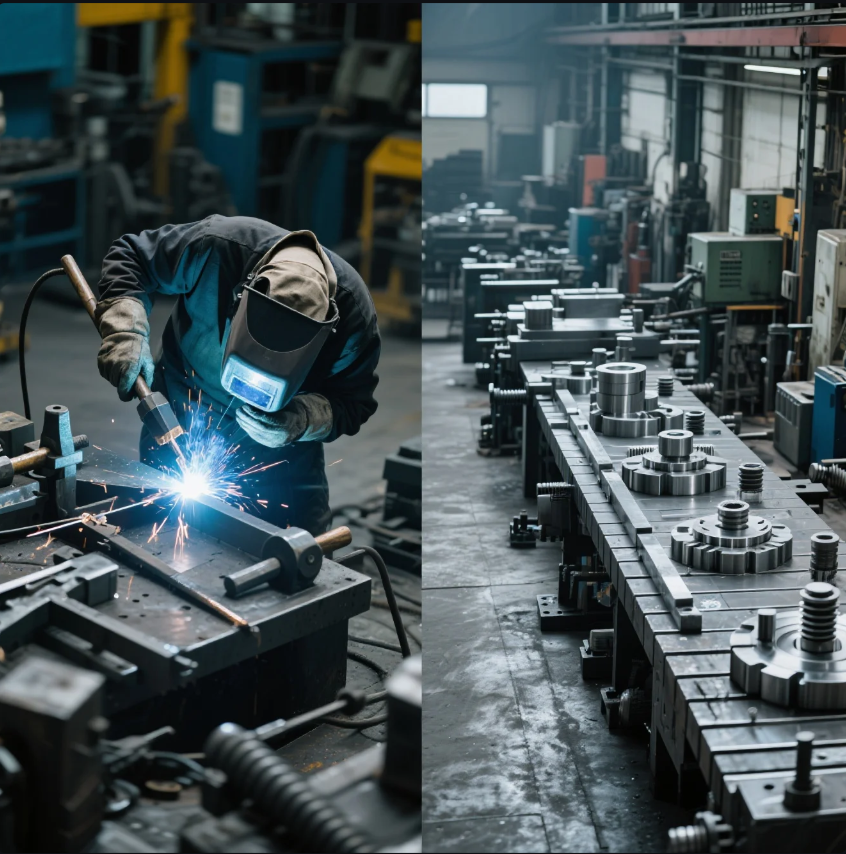

Is Metal Fabrication the Same as Welding?

Not exactly — welding is just one part of the larger process.

Welding is a joining technique used during fabrication. Fabrication includes cutting, bending, welding, and finishing.

Welding vs. Full Fabrication

| Process | Description | Part of Fabrication? |

|---|---|---|

| Cutting | Shapes raw metal | Yes |

| Welding | Joins two pieces | Yes |

| Polishing | Final surface finish | Yes |

| Fabrication | Combines all steps | — (umbrella term) |

So while every fabricator can weld, not every welder is a full fabricator.

FAQs

Q1: What metals are commonly used in fabrication?

Aluminum, stainless steel, carbon steel, copper, and brass.

Q2: What’s the difference between fabrication and machining?

Machining removes material via tools. Fabrication shapes and joins via cutting, bending, and welding.

Q3: Can I order a one-off fabricated part?

Yes. Prime supports low-volume and prototype orders.

Q4: What surface finishes are available?

We offer powder coating, anodizing, galvanizing, polishing, and more.

Q5: Do you handle large frame fabrication?

Yes. Our facility supports frame sizes up to 3 meters with welding, painting, and full packaging.

Contact Prime

Have a metal part in mind? Let’s fabricate it — from concept to reality.

📞 Request your free quote today:

👉 Visit: https://primecustomparts.com

📧 Email: [email protected]

With Prime, every part is made with precision, packed with care, and delivered on time.