What Is an Example of Metal Fabrication?

You’ve heard the term “metal fabrication” — but what does it actually look like?

A common example of metal fabrication is a custom electrical enclosure. It’s made by cutting, bending, and welding sheet metal into a protective box for electronics.

In this article, we’ll break down more examples and explain the core techniques used to create real, functional metal parts.

Table of Contents

- What Are Examples of Metal Fabrication?

- What Is Considered Metal Fabrication?

- What Are the Three Types of Metal Fabrication?

- What Are the 3 Metal Fabrication Techniques?

- FAQs

- Contact Prime

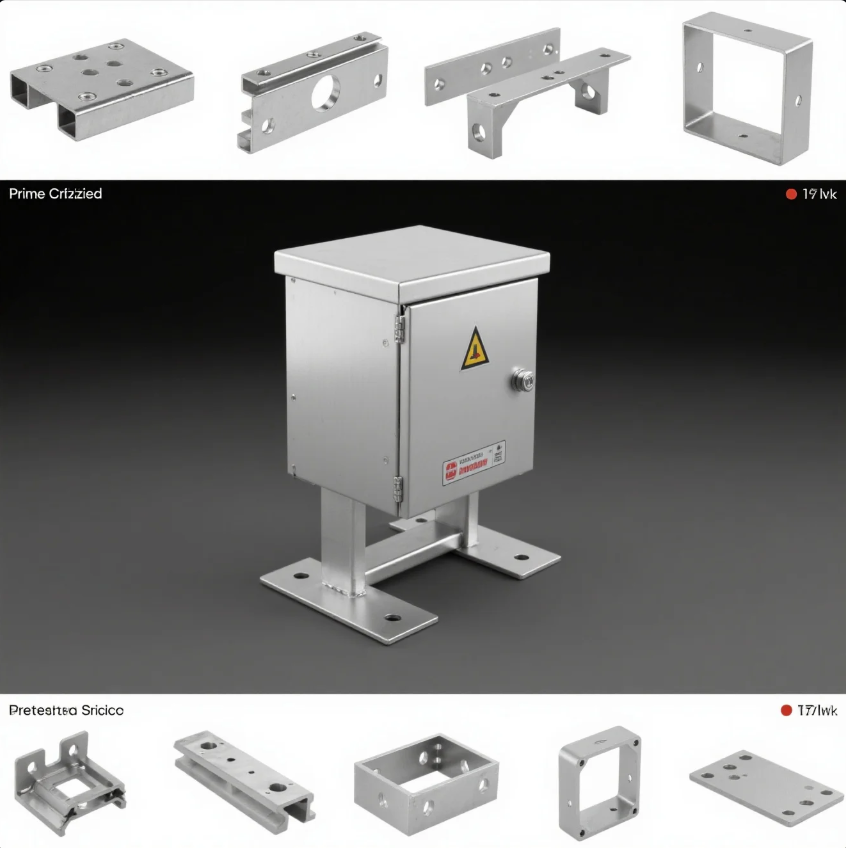

What Are Examples of Metal Fabrication?

Metal fabrication is everywhere — in factories, offices, vehicles, and homes.

Examples of metal fabrication include control cabinets, machine frames, HVAC ducting, furniture supports, brackets, and architectural panels.

Commonly Fabricated Metal Parts

| Product Example | Description | Where It’s Used |

|---|---|---|

| Electrical Enclosures | Sealed metal boxes for electronics | Automation, telecom |

| Machine Frames | Welded tube structures | Manufacturing, robotics |

| HVAC Duct Panels | Formed galvanized sheet | Buildings, ventilation systems |

| Brackets & Mounts | Cut and bent metal strips | Appliances, interiors |

| Tooling Plates | Precision milled parts | CNC setups, assembly jigs |

At Prime, we produce these using CNC laser cutting, press braking, TIG welding, and powder coating — built to meet international specs.

What Is Considered Metal Fabrication?

Metal fabrication includes any process that builds a product from raw metal materials.

It’s the combination of cutting, forming, and joining processes used to manufacture functional metal components or assemblies.

Processes Considered Fabrication

- Laser cutting, waterjet cutting, shearing

- Bending, rolling, deep drawing

- MIG/TIG welding, spot welding

- Surface finishing and assembly

Whether you’re creating a simple aluminum bracket or a complex stainless cabinet, if the part is made from raw material — that’s fabrication.

Custom metal fabrication means every detail — hole size, material grade, coating — follows your unique design.

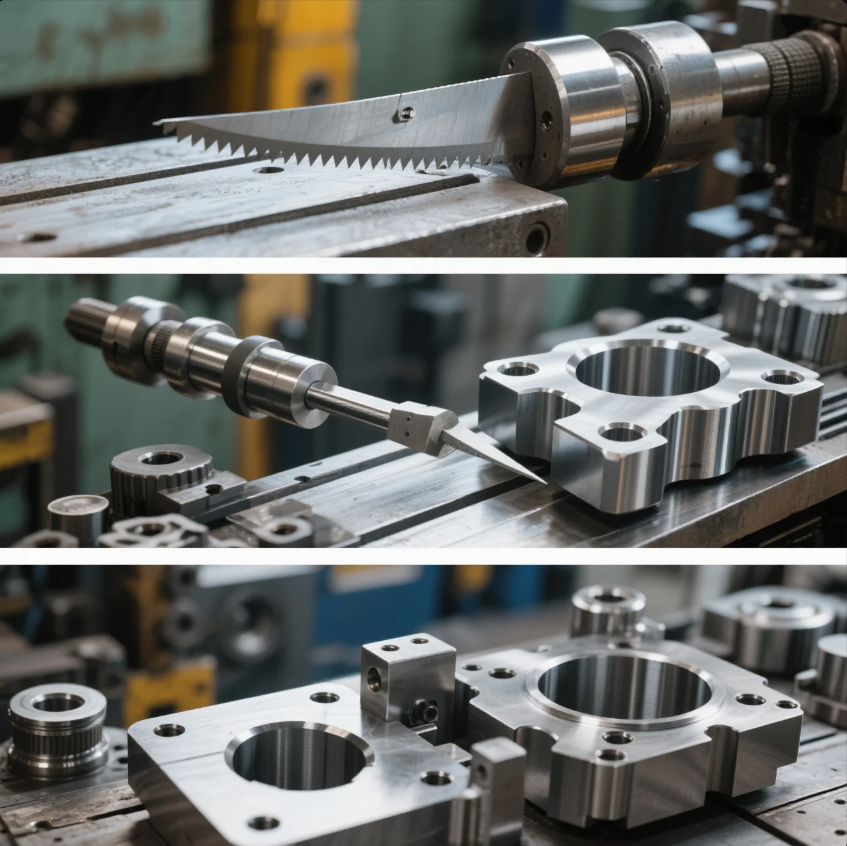

What Are the Three Types of Metal Fabrication?

To make a metal product, you need three key steps.

The three types of metal fabrication are: cutting, forming, and assembling. These processes define every fabricated part.

Summary of the 3 Types

| Process | Description | Tools Used |

|---|---|---|

| Cutting | Shapes the raw metal | Laser, plasma, waterjet, saw |

| Forming | Bends or curves material | Press brakes, rollers |

| Assembling | Joins cut and formed parts | Welding machines, rivets, bolts |

Each fabricated product uses one or more of these — sometimes all three.

At Prime, most projects start with a laser file and finish as welded, painted assemblies.

What Are the 3 Metal Fabrication Techniques?

The term “techniques” refers to how each type of fabrication is performed.

The 3 metal fabrication techniques are:

- Laser Cutting – fast, precise, for complex shapes

- Press Brake Forming – for bending sheet into panels and brackets

- MIG/TIG Welding – to join parts permanently

How These Techniques Work Together

For example, a machine enclosure:

- Starts as a laser-cut flat sheet

- Gets bent into shape with a press brake

- Then is welded and assembled into the final box

- After that, we add powder coating and QC inspection

That’s how the three core fabrication techniques come together in real-world production.

FAQs

Q1: Is CNC machining part of fabrication?

It can be. Machining is often used for holes, threads, or tight tolerance surfaces within fabricated assemblies.

Q2: Can I order fabricated parts in small quantities?

Yes. Prime supports low-volume, prototype, and batch production.

Q3: What materials do you work with?

We fabricate with aluminum, stainless steel, mild steel, galvanized steel, copper, and more.

Q4: What file formats do you accept?

We accept STEP, IGES, DXF, and PDF — or you can send a sketch with sizes.

Q5: Do you provide finishing services?

Yes. We offer powder coating, anodizing, galvanizing, polishing, and custom packaging.

Contact Prime

Now you know: what is an example of metal fabrication — and how it’s made.

📞 Ready to bring your idea to life with custom fabrication?

👉 Visit: https://primecustomparts.com

📧 Email: [email protected]

Prime is your trusted global partner for high-precision, on-time metal parts — from one-off prototypes to full production.