Metal Stamping Design Guide: 10 Critical Factors for Performance and Cost Efficiency

📚 Table of Contents

- What Is Design for Manufacturability (DFM) in Metal Stamping?

- Why Should I Optimize My Stamped Part Design?

- Summary Checklist

- Case Study: How Optimization Cut Costs by 32%

- When to Bring in Your Metal Stamping Partner?

- Contact Prime for a Free Design Review

What Is Design for Manufacturability (DFM) in Metal Stamping?

Kevin (Mechanical Buyer):

We’re developing a new bracket and want to avoid costly design mistakes. What exactly does DFM mean in metal stamping?

Leo (Senior Engineer, Prime):

DFM, or Design for Manufacturability, means designing a part with production in mind from the very beginning. In stamping, that includes material behavior, tool life, press tonnage, and forming limits. It helps ensure the part functions well and is easy to manufacture without issues or added cost.

Why Should I Optimize My Stamped Part Design?

Kevin:

Does design really have that much of an impact?

Leo:

Yes. Studies show that over 70% of part cost is set at the design stage. A better design means less waste, cheaper tooling, faster production, and fewer problems. Here’s what smart design can do:

| Optimization Area | Typical Benefit |

|---|---|

| Material savings | 5–15% less waste |

| Lower tooling complexity | 10–30% cost reduction |

| Faster cycle times | 10–25% speed improvement |

| Fewer defects | 50–80% fewer rejections |

| Longer tool life | 25–100% more uptime |

| Fewer secondary steps | Save 1–3 operations |

Let’s Walk Through the 10 Critical Design Factors

1. Material Selection

Leo:

Material drives both cost and manufacturability. For example, high-strength steel resists wear, but it’s harder to form and may require more press force.

Checklist:

- Match yield strength to formability

- Know how grain direction affects bends

- Avoid exotic grades unless necessary

- Ask about price and lead time

- Simulate forming for new alloys

2. Part Geometry and Complexity

Kevin:

We have some deep slots and raised forms in our part. Should we worry?

Leo:

Possibly. Irregular geometry makes tooling harder and adds forming steps. Try to:

- Keep shapes symmetrical

- Avoid sharp corners and tight channels

- Maintain consistent wall thickness

- Space features evenly

3. Tolerancing Strategy

Leo:

Not every dimension needs ±0.05 mm! Tolerances drive both cost and scrap. Use tight tolerances only where performance demands it.

Stamping Process Capabilities:

| Process | Tolerance Range |

|---|---|

| Progressive Die | ±0.05–0.13 mm |

| Deep Draw | ±0.13–0.25 mm |

| Fine Blanking | ±0.013–0.025 mm |

4. Bend Design and Springback Compensation

Kevin:

We’ve had trouble with bend angles shifting.

Leo:

That’s springback—especially common with stainless or high-strength steel. Use:

- Radius ≥ 1× thickness

- Reliefs for edge-adjacent bends

- K-factor values in flat patterns

- Forming simulations to predict angles

5. Hole and Slot Design

Leo:

Tiny holes or tight spacing can break punches or distort parts. Safe rules:

- Hole Ø ≥ thickness

- Edge clearance ≥ 2× thickness

- Slot width ≥ material thickness

- Use corner radii in slots

6. Corner and Edge Treatment

Leo:

Sharp corners cause cracks and tool damage. Use:

- Inside corner radii ≥ 0.5× thickness

- Rounded external edges

- Hemmed or flanged edges for safety

- Post-processing options if aesthetics matter

7. Drawn Features

Leo:

Drawing is tough. Success depends on depth, diameter, radius, and draft. Basic guidelines:

- Draw depth ≤ 2× diameter (unless staged)

- Radii ≥ 4–8× thickness

- Include draft angles for removal

- Use blank holders to prevent wrinkling

8. Assembly-Ready Design

Leo:

Add features that help in assembly:

- Locating tabs

- Self-aligning features

- Consistent fastener sizes

- Clearance for weld guns or rivet tools

- Features for robotic gripping or stacking

9. Secondary Operation Reduction

Leo:

Why do a post-process if it can be formed in-die?

- Design for in-die tapping or lancing

- Add slots for alignment instead of separate tools

- Use cleaner edges to avoid deburring

- Plan finishes to avoid masking issues

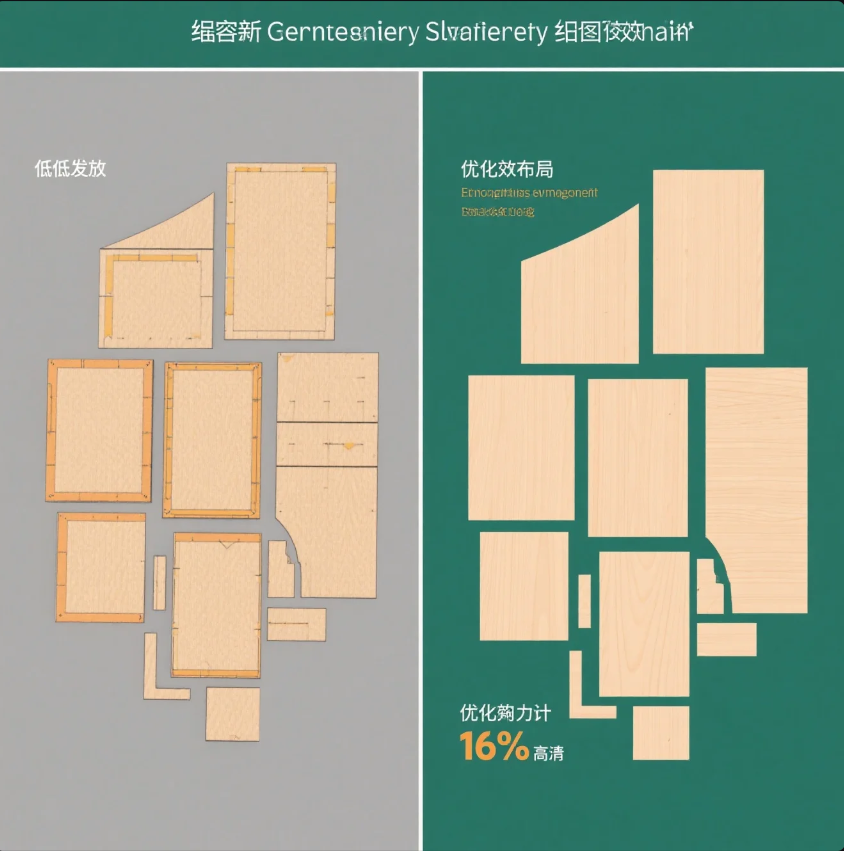

10. Cost Optimization

Leo:

Ask yourself: does this feature really add value?

- Optimize sheet nesting

- Avoid nonstandard sizes

- Simplify transitions and bends

- Reduce tool stations

- Balance function vs. manufacturability

Summary Checklist

✅ Material choice supports formability

✅ Geometry simplified, wall thickness consistent

✅ Tight tolerances only where needed

✅ Hole/slot/edge spacing meets standard

✅ Springback and grain direction considered

✅ Assembly features included

✅ No unnecessary second ops

✅ Designed with cost in mind

Case Study: How Optimization Cut Costs by 32%

Before:

- 35% scrap

- 12 tool stations

- 3 secondary processes

- 8% rejection rate

After Design Review:

- Material use: 65% → 78%

- Tooling: 12 → 8 stations

- In-die tapping added

- Tolerances revised

- 32% total cost savings

When to Bring in Your Metal Stamping Partner?

| Project Stage | How Prime Can Help |

|---|---|

| Early Concept | Feasibility, layout tips, material advice |

| CAD Development | Tolerance reviews, forming simulation |

| Drawing Finalization | Tooling plan, cost estimate |

| Pre-production | Prototype and test run setup |

The earlier we’re involved, the more value we can offer.

Contact Prime for a Free Design Review

📧 Email: [email protected]

🌍 Website: https://primecustomparts.com

At Prime Custom Parts, we help buyers and engineers design smarter stamped parts with better cost control, performance, and lead times.

Let’s make your next project a success—start with a free consultation today!

Let me know if you'd like this converted to a downloadable PDF or formatted for presentation decks.