Is Metal Fabrication the Same as Welding?

People often confuse the terms "fabrication" and "welding." While they’re closely related, they’re not the same.

Welding is just one process within the broader field of metal fabrication. Fabrication refers to everything required to create a finished metal product—including cutting, forming, assembling, and finishing.

Let’s break it down step by step so you can understand where welding fits—and when it's used.

Table of Contents

- Is Welding the Same as Metal Fabrication?

- What Are the Three 3 Types of Metal Fabrication?

- What Is Meant by Metal Fabrication?

- Does Fabricate Mean Weld?

- FAQs

- Contact Prime

Is Welding the Same as Metal Fabrication?

Welding is important—but it’s only part of the puzzle.

Fabrication includes welding, but also involves steps like laser cutting, bending, punching, and surface finishing. Welding specifically refers to joining metal components by melting and fusing their edges.

| Process | Purpose | Is It Welding? |

|---|---|---|

| Laser Cutting | Shapes raw sheet metal | No |

| Bending | Forms 2D material into 3D structures | No |

| Welding | Joins metal parts permanently | Yes |

| Riveting | Assembles with fasteners | No |

| Powder Coating | Adds surface protection | No |

So while welding is essential in many projects, it’s just one of many fabrication methods we use.

What Are the Three 3 Types of Metal Fabrication?

Understanding the bigger picture helps place welding in context.

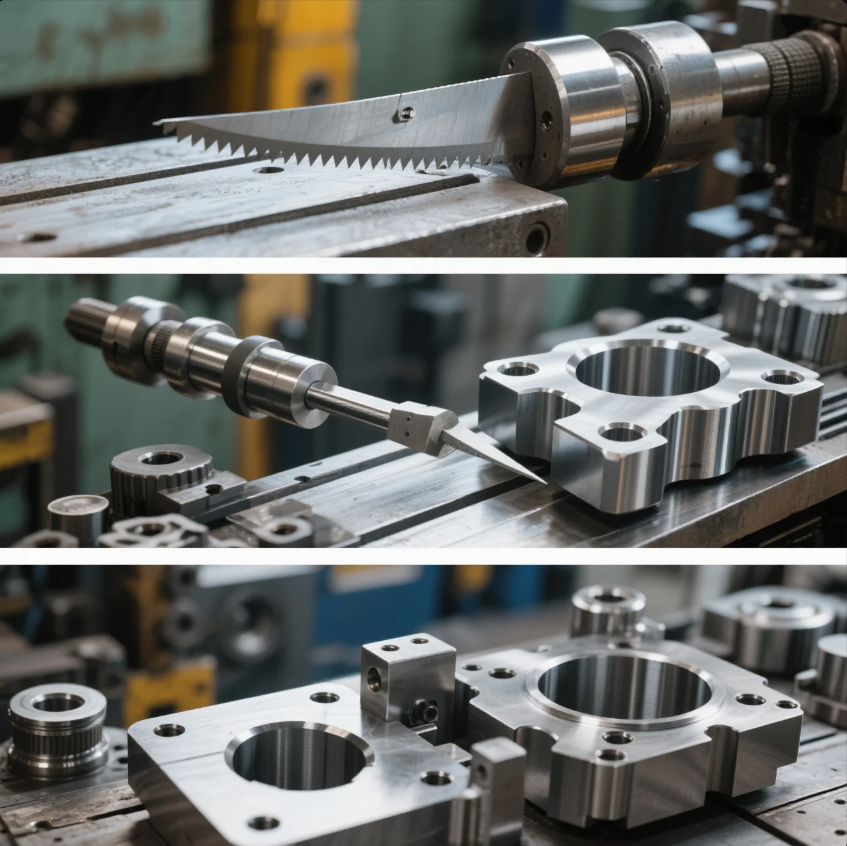

The three main types of fabrication processes are:

- Cutting – Material is shaped or trimmed to size

- Forming – Parts are bent, rolled, or stamped into shape

- Assembling – Components are joined, usually by welding, fastening, or bonding

Welding belongs to the “assembling” category. It’s often used when strength, durability, and permanent joins are required.

What Is Meant by Metal Fabrication?

Metal fabrication is the full process of turning raw materials into finished metal parts or assemblies.

This includes cutting sheets, forming brackets, joining frames, and preparing surfaces. The goal is to take raw steel, aluminum, or other materials—and deliver a product that fits your design exactly.

At Prime, our fabrication services include:

- CNC laser cutting

- Press brake forming

- TIG & MIG welding

- CNC machining

- Powder coating

- Quality control & packaging

Whether you're building industrial enclosures, brackets, housings, or mechanical frames, fabrication covers all the steps needed to get there.

Does Fabricate Mean Weld?

No. Fabrication does not mean welding—but welding is often included.

Welding is one possible technique for assembling parts. However, many fabrications use bolts, rivets, tabs, or adhesive systems instead—especially when disassembly or flexibility is needed.

For example:

- Control panels may be fabricated entirely by bending and screwing

- Steel frames for machines may be fully welded for strength

- Sheet metal covers might use clinching or spot welding only

Your design, application, and load requirements determine if welding is required.

FAQs

Q1: Do all fabricated parts require welding?

No. Some assemblies are bolted, riveted, or folded.

Q2: Is welding stronger than bolting?

It depends on the application. Welding is better for vibration resistance, while bolting allows easier maintenance.

Q3: What welding methods does Prime offer?

We provide TIG, MIG, and spot welding—suitable for aluminum, carbon steel, and stainless.

Q4: Can I submit designs that avoid welding?

Yes. We can recommend bolt-together alternatives or fold-based structures.

Q5: Can I request only welding services?

We typically include welding as part of full fabrication projects—not standalone jobs.

Contact Prime

Still not sure if your part should be welded, riveted, or bent? We can help.

📧 Email: [email protected]

🌐 Visit: https://primecustomparts.com

At Prime, we offer complete fabrication services from raw material to finished product—welding included. Let us help you choose the best process for performance, cost, and lead time.