Short-Run Metal Stamping: The Agile Solution for Modern Manufacturing

In today's fiercely competitive manufacturing landscape, businesses constantly seek production methods that enhance efficiency, reduce costs, and maintain superior product quality. Short-run metal stamping, as a flexible and efficient manufacturing process, is increasingly becoming the preferred solution across numerous industries. This technique not only caters to the demands of low-volume production but also offers significant cost and time advantages while ensuring precision and quality.

Metal stamping is a process that utilizes dies and pressure to shape metal materials into specific forms. Short-run metal stamping specifically refers to stamping production tailored for low-volume, customized requirements, often employed in prototype development, small-scale production runs, or the manufacturing of specialized components. Compared to traditional high-volume stamping, short-run stamping boasts greater flexibility and adaptability, enabling rapid responses to market shifts and evolving customer needs.

This article will delve into the multifaceted benefits of short-run metal stamping, including its exceptional cost-effectiveness, rapid turnaround capabilities, precision tolerance achievement, consistent quality assurance, and robust customization potential. Furthermore, we will analyze its application scenarios across various industries, providing manufacturing procurement personnel and engineers with a comprehensive understanding of this process to inform their project decisions. Whether you are seeking ways to lower production costs or need to swiftly transform designs into tangible products, short-run metal stamping presents a compelling solution worth considering.

Table of Contents

- Short-Run Metal Stamping: The Agile Solution for Modern Manufacturing

- Core Advantages of Short-Run Metal Stamping

- Industry Applications Analysis

- In-Depth Cost-Effectiveness Analysis

- Customization Capabilities and Flexibility

- Quality Control and Assurance Systems

- Material Diversity and Applications

- Conclusion

Core Advantages of Short-Run Metal Stamping

Cost-Effective Production

In today's competitive manufacturing environment, achieving cost-effective production in short-run metal stamping requires strategic planning and efficient resource utilization. Companies must carefully manage material usage, production processes, and labor costs to stay within budget constraints. One effective approach is employing precise engineering and design techniques to minimize waste and ensure each stamping meets exact specifications. This not only reduces material costs but also diminishes the need for rework, which can be both time-consuming and expensive.

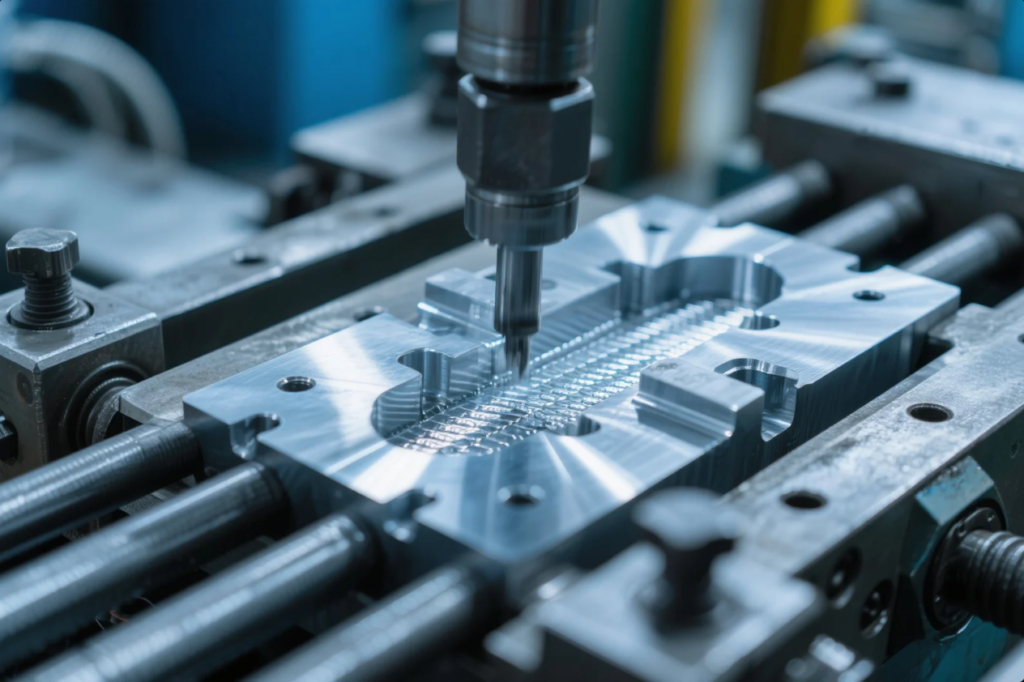

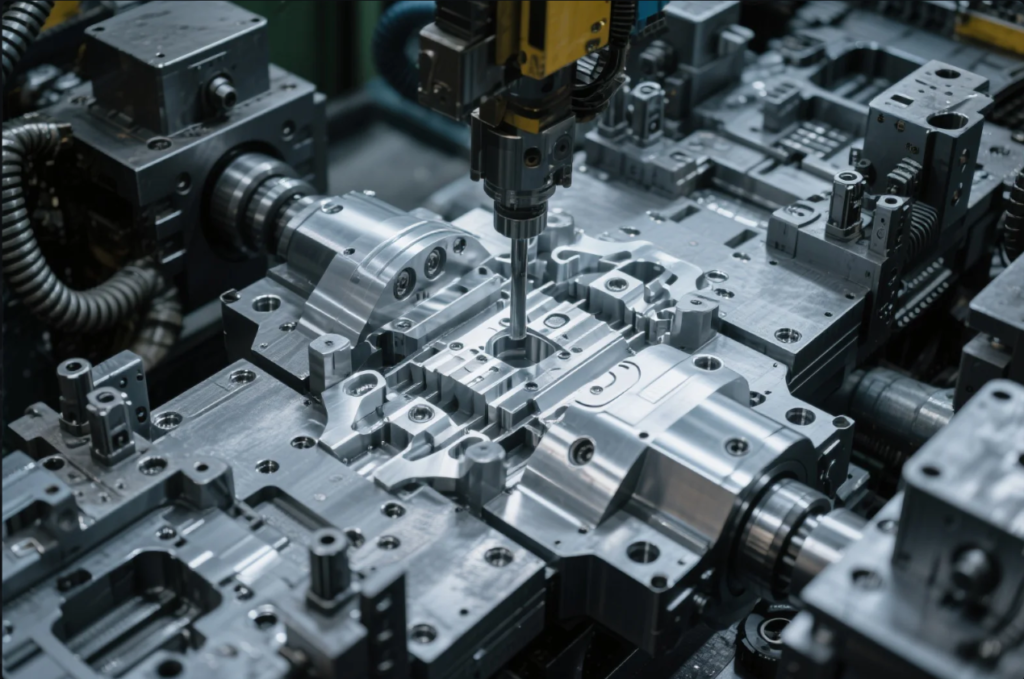

Leveraging advanced technologies such as CNC machines and CAD software can significantly streamline production. These tools enable companies to create detailed prototypes and make adjustments quickly, ensuring the final product is both high-quality and cost-effective. By investing in appropriate equipment and software, businesses can also reduce setup times and increase overall efficiency, creating greater value in the long term.

For projects requiring limited quantities of parts, partnering with or outsourcing to specialized manufacturers who possess the expertise and equipment needed for short-run metal stamping often proves more cost-effective than handling everything in-house. This strategy allows companies to leverage the specialist's expertise and equipment without bearing substantial upfront investments, while maintaining product quality and delivery efficiency.

Quick Turnaround Times

Achieving quick turnaround times in short-run metal stamping demands not only cost-effective strategies but also streamlined workflows and efficient scheduling. When working on projects with tight deadlines, every minute counts. Short-run metal stamping services excel in meeting these demands by minimizing setup times and employing flexible manufacturing processes. This ensures parts are delivered faster, reducing the time your project spends in the production phase.

Compared to high-volume production, short-run metal stamping typically employs simpler, less complex tooling. This means less time is required for initial setup, allowing production to commence more rapidly. The streamlined tooling also means changes can be implemented quickly if adjustments are needed during the production process.

By choosing short-run metal stamping, companies gain the advantage of rapid prototyping and production cycles. This agility allows businesses to respond quickly to market changes and customer needs. With fewer tooling requirements compared to longer production runs, the time from design to delivery is notably shortened. Companies can bring their products to market faster, gaining a competitive edge.

Many short-run metal stamping providers offer just-in-time delivery services. This means companies can synchronize their production schedules with their supply chains, avoiding delays and ensuring parts are available exactly when needed. Leveraging these quick turnaround capabilities ensures projects stay on track and within expected timelines.

Tight Tolerance Achievement

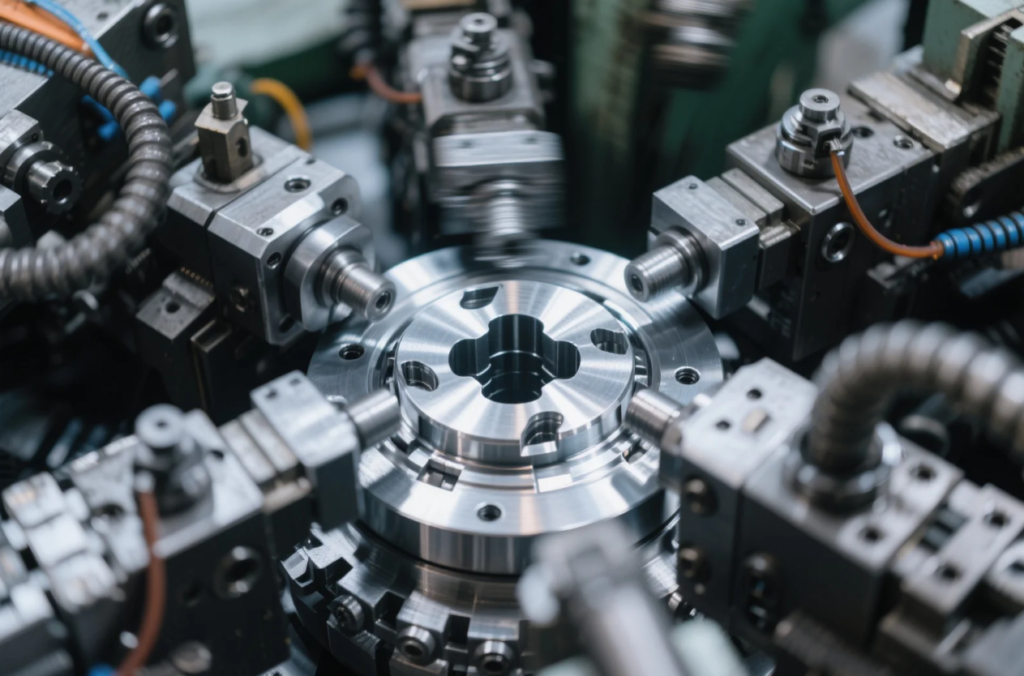

In the realm of short-run metal stamping, achieving high precision and tight tolerances is crucial. This process ensures each part meets exact specifications and consistently delivers quality results. The ability to accurately reproduce detailed designs captures every intricate feature of the original blueprint.

Achieving these tight tolerance requirements demands a meticulous approach and the use of advanced machinery. High-quality stamping presses capable of handling tolerances within a few thousandths of an inch are essential. Such precision ensures each piece fits perfectly in its intended application, reducing the risk of assembly issues or functional failures.

The expertise of skilled technicians plays a vital role in maintaining this high level of precision. These professionals understand the nuances of metal behavior under various conditions and can make necessary adjustments to ensure accuracy. Factors like material thickness, type, and design complexity are all taken into account to ensure the final product meets stringent standards.

Advanced quality control systems are also integral to the process. Real-time monitoring and inspection catch any deviations immediately, allowing for quick corrections. This proactive approach helps avoid costly mistakes and guarantees that the final product meets exacting standards.

Achieving high precision and tight tolerances in short-run metal stamping involves a combination of precise engineering, expert knowledge, and cutting-edge technology to ensure every part meets the highest quality standards.

Quality Consistency

Maintaining consistent quality in short-run metal stamping is essential for meeting high project standards. Each piece must meet exact specifications to ensure reliability and performance, achievable through advanced machinery and meticulous quality control.

Quality control teams often utilize statistical process control (SPC) methods and real-time monitoring systems. These tools help identify any potential issues early in the production process, allowing for immediate corrective actions. As a result, customers receive parts that not only meet but often exceed industry standards for consistency and precision.

Short-run metal stamping allows for iterative testing and refinement of designs. By producing small batches, companies can test and evaluate parts, identify any issues, and make necessary adjustments before scaling up production. This iterative approach ensures any flaws are addressed early, leading to more precise and reliable final products.

Short-run metal stampings provide a reliable way to achieve consistent part quality for projects, ensuring each component meets stringent performance and reliability requirements.

Detailed Design Reproduction

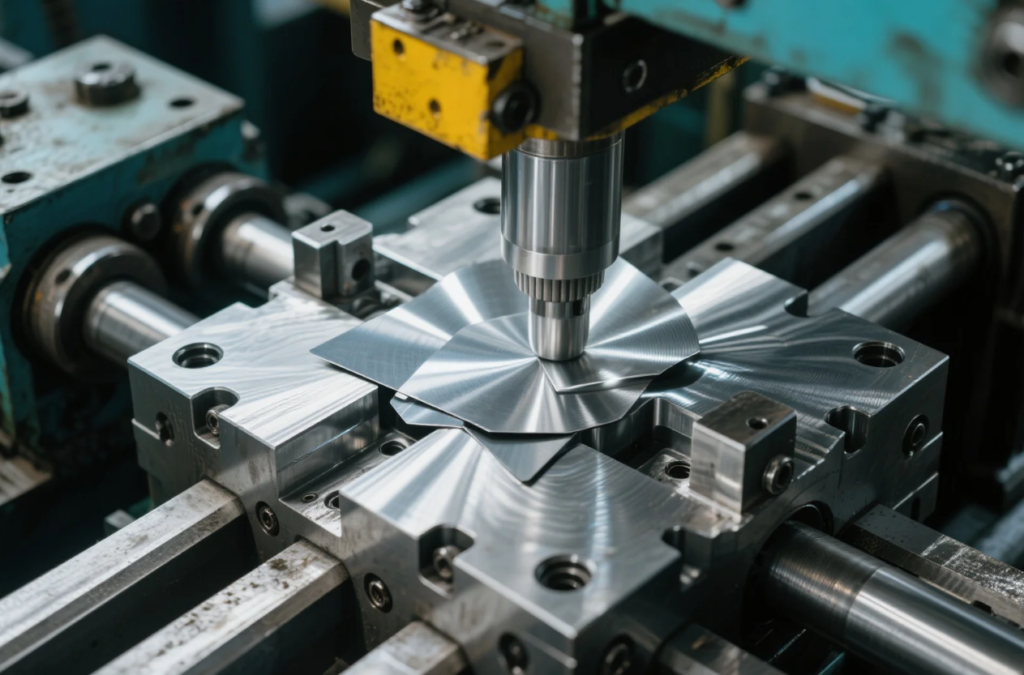

Guaranteeing high precision in detailed design reproduction demands cutting-edge technology and expert craftsmanship. When you opt for short-run metal stamping for your project, you're selecting unmatched accuracy and meticulous attention to detail. Whether your design includes intricate patterns, tight tolerances, or complex geometries, the precision of short-run metal stamping ensures every feature is replicated perfectly.

Modern stamping technologies, like CNC machining and laser cutting, allow for high fidelity in reproducing detailed designs. Skilled technicians use these advanced tools to deliver parts that meet exact specifications. This ensures each piece fits seamlessly into larger projects, reducing assembly time and minimizing waste.

Short-run metal stamping offers high precision, quick setup times, and cost-effectiveness, making it an ideal choice for detailed design reproduction. Choosing this method guarantees that projects not only meet but exceed quality standards, adding value and reliability to the final product.

Reduced Waste

Short-run metal stampings are designed to maximize material efficiency and minimize waste, ensuring optimal utilization of every sheet of metal. This approach not only saves time and resources but also supports a more sustainable manufacturing process.

Precision Engineering: Advanced software meticulously plans part layouts, ensuring each piece fits together like a puzzle, minimizing unused material.

Batch Customization: Short-run stamping allows for quick adjustments during the production process. Companies can customize each batch to optimize material usage, reducing waste with every run.

Material Selection: Choosing the right type and thickness of material for a project helps further reduce waste. Materials that are easier to stamp and form improve production efficiency.

Focusing on minimizing scrap rates is essential for enhancing efficiency in short-run metal stamping projects. By reducing scrap, companies save on material costs and contribute to a more sustainable production process. Short-run stamping allows for fine-tuning production runs, making it easier to identify and correct early inefficiencies, ensuring less material ultimately becomes waste.

The benefits of reduced waste include cost savings (lower scrap rates mean material savings, directly impacting the bottom line), resource allocation (materials saved from waste can be redirected to additional production, increasing total output), project timelines (reduced waste leads to more predictable production processes, helping meet deadlines), and operational efficiency (fewer interruptions and delays result from streamlined processes, improving overall efficiency).

Short-run metal stamping provides an effective way to achieve efficient material usage and reduced waste, balancing budget considerations with environmental responsibility.

Industry Applications Analysis

Short-run metal stamping, with its flexibility, precision, and cost-effectiveness, has become an indispensable manufacturing process across multiple key industries. Understanding how this technology applies in different sectors helps manufacturing professionals better evaluate its potential for specific projects.

Automotive Industry Applications

The automotive industry is one of the primary beneficiaries of short-run metal stamping. In this competitive and constantly innovating field, manufacturers need to quickly adapt to design changes, test new concepts, and produce small batches of specialized parts. Short-run metal stamping provides an ideal solution for prototype development, allowing engineers to validate design concepts before committing to large-scale production.

For custom vehicle models, racing components, or classic vehicle restoration projects, short-run metal stamping is particularly valuable. These applications typically require high-precision but limited quantities of parts, making traditional high-volume production methods economically unfeasible. Through short-run stamping, automotive manufacturers can produce everything from dashboard components to structural supports while maintaining strict quality standards and material specifications.

With the rapid growth of the electric vehicle market, short-run metal stamping also plays a crucial role in developing and producing components for new energy vehicles. These innovative products often require rapid iteration and small-batch production, perfectly aligning with the advantages of short-run stamping.

Aerospace Sector Requirements

The aerospace industry imposes extremely stringent requirements on components, demanding not only exceptional precision and reliability but also material performance capable of withstanding extreme conditions. Short-run metal stamping meets these high standards while accommodating the industry's characteristic small-batch, high-value production model.

During aircraft development, prototyping and testing are critical phases. Short-run metal stamping allows engineers to rapidly produce test components, validate designs, and make necessary modifications without investing in expensive full-scale production tooling. This flexibility is particularly important for specialized components in satellites, drones, and other aerospace equipment.

The aerospace industry also frequently requires maintenance and replacement parts for older aircraft that may no longer be in mass production. Short-run metal stamping provides an economically viable way to produce these low-demand but critical replacement components, ensuring older equipment can continue to operate safely.

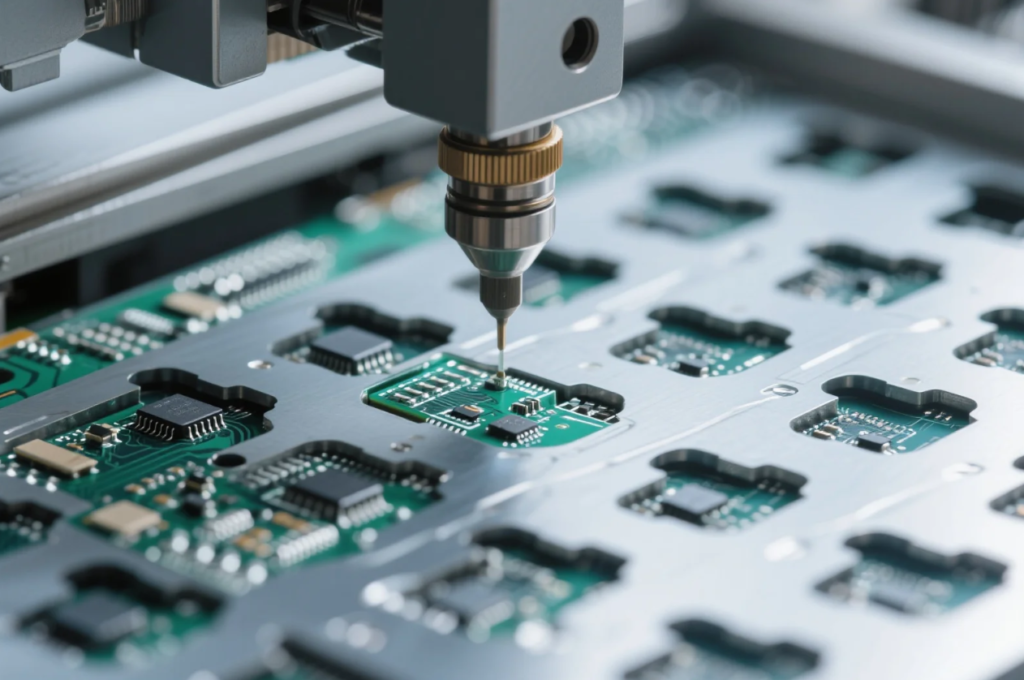

Electronics Manufacturing

The rapid pace of development and increasingly shorter product lifecycles in the electronics industry make short-run metal stamping an ideal choice. From smartphones and tablets to servers and networking equipment, modern electronic devices require precision metal components that not only meet functional requirements but also fit into increasingly compact designs.

Short-run metal stamping excels in producing electronic device housings, heat sinks, shielding covers, and connectors. These components typically require precise dimensions and good surface finishing to ensure the performance and reliability of electronic devices. Through short-run stamping, electronics manufacturers can quickly adjust designs to respond to market demand changes or address discovered issues.

With the rise of IoT devices and wearable technology, demand for small, lightweight, yet durable metal components continues to grow. Short-run metal stamping can meet the needs of these emerging applications, providing solutions that are both aesthetically pleasing and functional.

Medical Device Industry

The medical device industry demands exceptionally high component quality and reliability, while also requiring manufacturing methods that can accommodate personalized medical solutions. Short-run metal stamping demonstrates unique value in this field, capable of producing high-precision medical components that comply with strict regulatory standards.

From surgical instruments to implant supports, medical devices often require precision parts manufactured from special materials such as medical-grade stainless steel or titanium alloys. Short-run metal stamping can not only process these special materials but also ensure the final products meet the strict hygiene and safety standards of the medical industry.

For customized medical devices or small-batch specialized equipment, short-run metal stamping provides an economically efficient production path, enabling medical innovations to transition more quickly from concept to practical application, ultimately benefiting patients.

Other Benefiting Industries

Beyond the major industries mentioned above, short-run metal stamping plays important roles in numerous other fields:

The energy sector relies on short-run metal stamping to produce solar panel brackets, wind turbine components, and battery casings. These applications typically require corrosion-resistant, heat-resistant materials and precise manufacturing processes.

The consumer goods industry utilizes short-run metal stamping to produce everything from high-end kitchenware to decorative hardware. These applications often emphasize the balance between aesthetics and functionality, requiring fine surface finishing and consistent quality.

Industrial equipment manufacturers use short-run metal stamping to produce specialized machine parts, sensor housings, and control panels. These applications typically require durable, precise components that can reliably operate in harsh environments.

Regardless of the industry, short-run metal stamping offers flexibility, precision, and cost-effectiveness, providing manufacturers with an efficient solution for small-batch, high-value production needs. As manufacturing technologies continue to evolve and market demands change, the application areas for short-run metal stamping will continue to expand, bringing innovation and efficiency to more industries.

In-Depth Cost-Effectiveness Analysis

In the manufacturing decision-making process, cost-effectiveness analysis stands as one of the most critical considerations. Short-run metal stamping, as a specialized manufacturing process, exhibits a cost structure significantly different from traditional high-volume production methods. Understanding these differences helps businesses make more informed investment decisions and optimize resource allocation.

Initial Investment and Long-Term Returns

A notable advantage of short-run metal stamping lies in its lower initial investment requirements. Compared to high-volume production, short-run stamping typically utilizes simpler, less expensive tooling and dies. This difference is particularly important for small and medium-sized enterprises or startups with limited capital, enabling them to obtain high-quality metal components without bearing enormous upfront costs.

From a long-term returns perspective, short-run metal stamping offers a more flexible investment model. Companies can gradually adjust designs and invest funds in stages based on market feedback and product performance, rather than committing large amounts of capital to designs that might require modification. This progressive investment approach reduces risk and improves capital utilization efficiency.

Furthermore, short-run metal stamping helps companies avoid inventory accumulation and overproduction risks. By producing appropriate quantities of parts on demand, businesses can reduce storage costs and capital tie-up, enhancing overall financial flexibility.

Cost Comparison with Traditional Manufacturing Methods

Comparing short-run metal stamping with other manufacturing methods reveals its economic advantages more clearly:

Compared to traditional high-volume stamping, short-run stamping offers significant cost advantages for small-batch production. While the unit cost may be slightly higher, when considering tooling investment, setup time, and minimum order quantities, short-run stamping typically provides a more competitive overall solution.

Compared to alternative methods like CNC machining, short-run metal stamping often performs better in terms of production speed and material utilization. Although CNC machining offers flexibility, it typically involves more material waste and longer processing times, especially as production quantities increase.

Compared to 3D printing metal components, short-run metal stamping can provide better surface quality and mechanical properties, while also offering advantages in production speed and cost, particularly when part quantities exceed just a few units.

Balancing Economies of Scale with Small-Batch Production

The uniqueness of short-run metal stamping lies in its ability to achieve a degree of economies of scale even in small-batch production. Through optimized process flows, well-planned production schedules, and advanced equipment utilization, professional short-run stamping suppliers can offer competitive unit costs while maintaining flexibility.

For many businesses, finding the balance point between the scale benefits of high-volume production and the flexibility of small-batch production is crucial. Short-run metal stamping provides an ideal middle-ground solution, allowing companies to adjust production volumes according to actual needs without overproducing to reduce unit costs.

As market demand uncertainty increases and product lifecycles shorten, this flexibility becomes increasingly valuable. Companies can quickly switch between different products through short-run metal stamping, responding to market changes while maintaining a reasonable cost structure.

Outsourcing vs. In-House Production Cost Considerations

For many businesses, especially small to medium-sized manufacturers, choosing between outsourcing short-run metal stamping or building internal capabilities represents an important decision. This decision requires consideration of multiple factors:

Outsourcing to professional short-run metal stamping suppliers typically avoids substantial equipment investments and technical personnel training costs. Professional suppliers already possess advanced equipment and experienced technical teams, capable of providing high-quality services without requiring customers to invest themselves.

However, outsourcing also involves logistics costs, communication coordination costs, and supplier dependency risks. Companies need to weigh these factors and consider the importance of short-run metal stamping in their overall business strategy.

For companies frequently requiring short-run metal stamping services, establishing long-term partnerships with reliable suppliers may be the most cost-effective solution. Such relationships can bring better pricing conditions, faster response times, and more in-depth technical support.

Hidden Costs and Total Cost of Ownership

When evaluating the cost-effectiveness of short-run metal stamping, companies should consider not only direct production costs but also various hidden costs and total cost of ownership:

Time cost represents a key consideration factor. Short-run metal stamping can significantly shorten the cycle from design to production, enabling products to enter the market faster, creating earlier revenue streams and competitive advantages.

Quality costs cannot be overlooked. High-quality short-run metal stamped parts can reduce assembly problems, rework requirements, and customer complaints, thereby lowering quality-related hidden costs.

Flexibility value, though difficult to quantify, is crucial for companies responding to market changes and technological developments. The design flexibility and rapid iteration capabilities provided by short-run metal stamping can help businesses maintain innovation and competitiveness.

Considering all these factors, short-run metal stamping typically offers better overall economic value than surface cost figures suggest, especially during early product development stages, in situations of high market uncertainty, or when customization demands are strong.

Customization Capabilities and Flexibility

In today's rapidly changing manufacturing environment, customization capabilities and flexibility have become key competitive advantages for businesses. Short-run metal stamping excels particularly in these areas, providing unprecedented design freedom and production flexibility for various projects. Whether for prototype development or small-batch production, this process can meet stringent specifications while remaining economically viable.

Design Flexibility and Modification Ease

A significant advantage of short-run metal stamping is its exceptional design flexibility. Compared to high-volume production, short-run stamping allows engineers and designers to explore innovative concepts more freely without concerns about high tooling modification costs. This flexibility is especially valuable during early product development stages when designs may require multiple iterations and improvements.

In short-run metal stamping, design modifications can be implemented quickly without going through the complex and time-consuming tooling change processes typical in traditional high-volume production. This means companies can rapidly adjust product designs based on test results, customer feedback, or changing market demands. This agility not only accelerates product development cycles but also enhances the quality and market adaptability of final products.

Design flexibility is also reflected in short-run metal stamping's ability to handle various complex shapes and features. From simple flat components to complex structures with multiple bends, perforations, or embossing, short-run stamping can achieve precise results. This enables engineers to optimize designs based on functional requirements rather than manufacturing limitations, creating higher-performing products.

Tooling Adaptability

Short-run metal stamping typically employs simpler, more economical tooling solutions that can be fabricated and modified more quickly. Compared to the hard dies used in traditional high-volume production, short-run stamping may utilize soft dies, combination dies, or other flexible tooling technologies, significantly reducing tool costs and production time.

This tooling strategy flexibility makes short-run metal stamping particularly suitable for handling diverse small-batch orders. Manufacturers can quickly switch between different product productions without lengthy equipment adjustments or expensive tooling replacement costs. This represents a significant advantage for businesses needing to produce multiple variants or frequently update product lines.

Additionally, the tooling adaptability of short-run metal stamping is evident in its ability to handle various materials and thicknesses. The same basic tooling can often be adapted to different material characteristics through simple adjustments, allowing manufacturers to select the most appropriate materials based on specific application requirements without developing entirely new tooling for each material.

Fine Detail Implementation

Despite short-run metal stamping's focus on flexibility and cost-effectiveness, this doesn't mean compromising on fine details. On the contrary, modern short-run stamping technology can achieve extremely high levels of precision and detail representation, meeting the most demanding design requirements.

From tiny positioning holes to complex contour lines, short-run metal stamping can precisely replicate every detail in a design. This precision not only ensures component functionality but also guarantees perfect fit between multiple components, reducing assembly issues and rework requirements.

For applications requiring special surface treatments or decorative effects, short-run metal stamping can also provide various solutions. From simple surface textures to complex embossed patterns, these details can be achieved directly in the stamping process without additional post-processing steps, saving time and costs.

Rapid Prototype Validation Benefits

A key advantage of short-run metal stamping in the product development process is its ability to support rapid prototype validation. Compared to relying solely on computer simulations or 3D printed models, metal stamped prototypes can more realistically represent the performance and characteristics of final products.

By producing functional prototypes through short-run metal stamping, engineers can conduct actual physical tests to verify design strength, durability, and functionality. This testing based on real materials and manufacturing processes can reveal issues potentially overlooked by pure digital simulation, allowing potential defects to be discovered and resolved early in product development.

Rapid prototype validation also enables companies to more confidently showcase product concepts to potential customers or investors. Physical samples are more convincing than drawings or renderings, more effectively conveying product value and functionality. In competitive markets, this capability may become a key factor in winning projects or securing funding.

Economic Viability of Small-Batch Production

Short-run metal stamping breaks the traditional manufacturing rule that "low quantity equals high cost." By optimizing process flows and tooling design, short-run stamping makes small-batch production economically viable, providing businesses with more options.

This economic viability allows companies to adopt more flexible production strategies, such as on-demand or batch production. This not only reduces inventory risk but also enhances responsiveness to market changes. Businesses can adjust production plans based on actual sales performance, avoiding overproduction or inventory shortage issues.

For seasonal products, regional variants, or special market demands, short-run metal stamping provides an ideal production method. Companies can produce customized versions for different markets or customer groups without worrying about not reaching the minimum economic scale of traditional high-volume production.

The customization capabilities and flexibility of short-run metal stamping bring new possibilities to modern manufacturing, enabling businesses to provide more personalized, more innovative product solutions while maintaining cost competitiveness. As market demands for customization and quick response grow, these advantages will become increasingly important, serving as key factors for manufacturing business success.

Quality Control and Assurance Systems

In manufacturing, product quality affects not only customer satisfaction but directly impacts company reputation and long-term development. As a precision manufacturing process, quality control systems are particularly important in short-run metal stamping. Comprehensive quality assurance measures ensure each stamped component meets design specifications, satisfying or even exceeding customer expectations. This section explores quality control methods, technology applications, and continuous improvement mechanisms in short-run metal stamping.

Advanced Machinery and Technology Applications

Quality control in short-run metal stamping begins with advanced equipment implementation. Modern stamping equipment features high-precision control systems capable of precise adjustment of pressure, speed, and position, ensuring consistency in each stamping operation. These machines typically employ closed-loop control systems that monitor key parameters in real-time and adjust automatically, minimizing quality fluctuations caused by human factors.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies play crucial roles in short-run metal stamping quality control. These technologies are used not only for design optimization but also for simulation analysis to predict potential manufacturing issues such as uneven material flow, stress concentration, or springback. By identifying and resolving these problems before actual production, the quality and consistency of final products can be significantly improved.

Three-dimensional measurement technology and optical scanning systems provide powerful quality verification tools for short-run metal stamping. These systems can quickly and accurately measure the geometric dimensions and surface features of stamped parts, comparing them with design models to identify any deviations. Advanced systems can even generate heat maps visually displaying differences between stamped parts and ideal models, helping engineers precisely locate and resolve issues.

The Role of Technical Professionals

Despite significant technological advances, experienced technical personnel remain irreplaceable in short-run metal stamping quality control. These professionals, with years of accumulated knowledge and experience, can identify potential problems, interpret complex data, and make critical decisions.

Die designers and engineers play important roles at the front end of quality control. They are responsible not only for creating precise die designs but also for considering material characteristics, stamping process parameters, and potential manufacturing challenges. By applying design optimization techniques such as finite element analysis (FEA), they can predict and resolve issues that might affect product quality.

Operating technicians are key links in the quality control chain. They handle equipment debugging, parameter setting, and daily monitoring, ensuring the stamping process proceeds according to established standards. These technicians typically receive specialized training, enabling them to identify abnormal situations and take appropriate measures to prevent defective product generation.

Quality inspectors are responsible for final product verification and certification. Using various measurement tools and testing equipment, they conduct comprehensive assessments of stamped parts according to predetermined quality standards and inspection procedures. This stage not only ensures products meet customer requirements but also provides valuable data for continuous improvement.

Quality Monitoring Systems and Methods

Quality control in short-run metal stamping typically employs multi-level monitoring systems ensuring comprehensive quality management from raw materials to finished products. These systems combine traditional quality control methods with modern digital technologies, forming a comprehensive and efficient quality assurance network.

Statistical Process Control (SPC) is a widely applied quality monitoring method in short-run metal stamping. By collecting and analyzing data on key quality characteristics, SPC can identify trends and patterns of process variation, predicting potential quality issues. This preventive approach allows manufacturers to intervene before problems lead to defective products, greatly improving quality stability and production efficiency.

Real-time monitoring systems are increasingly common in modern stamping equipment. These systems collect various process parameters through sensor networks, including pressure, temperature, vibration, and acoustic signals, comparing this data with preset standards. When anomalies are detected, the system immediately issues alerts or even automatically adjusts parameters or stops production, preventing defective product generation.

Batch traceability systems are important components of short-run metal stamping quality control, especially in high-requirement industries like aerospace and medical devices. These systems record complete production histories for each batch of products, including raw material information, process parameters, operators, and quality inspection results. When quality issues arise, specific batches and possible causes can be quickly traced, enabling precise problem-solving and risk control.

Iterative Testing and Continuous Improvement

A significant advantage of short-run metal stamping is its support for iterative testing and continuous improvement. With smaller production batches, manufacturers can evaluate and adjust between batches, constantly optimizing product quality and production efficiency.

First article inspection is a commonly used quality control method in short-run metal stamping. At the beginning of each production batch, one or several samples are first produced for comprehensive testing. Only when these samples fully meet requirements does batch production continue. This method can identify and resolve potential problems early, avoiding large quantities of defective products.

Process capability analysis helps manufacturers assess their production systems' ability to meet quality requirements. By calculating statistical indicators such as process capability index (Cpk), the stability and precision of production processes can be quantified. These analysis results provide clear directions for process improvement, guiding manufacturers to optimize equipment, tools, and parameter settings.

A continuous improvement culture forms the foundation of high-quality short-run metal stamping. Excellent manufacturers are not satisfied with merely meeting minimum requirements but constantly seek methods to improve quality standards and production efficiency. They encourage employee participation in quality improvement activities, collect customer feedback, and invest in new technologies and training, ensuring quality control systems remain current.

Quality Certifications and Standards

For many industries, particularly automotive, aerospace, and medical devices, quality certification represents an important consideration factor when selecting short-run metal stamping suppliers. These certifications not only demonstrate suppliers' quality management capabilities but also ensure their production processes comply with industry standards and regulatory requirements.

ISO 9001 is the most basic and widely recognized quality management system standard. Short-run metal stamping suppliers obtaining this certification demonstrate they have established systematic quality management processes capable of consistently providing products that meet customer and applicable regulatory requirements.

Industry-specific certifications, such as IATF 16949 for the automotive industry, AS9100 for aerospace, or ISO 13485 for medical devices, are particularly important for suppliers providing short-run metal stamping services in these fields. These certifications include more stringent requirements and industry-specific quality control measures.

Material traceability and test reports form important components of short-run metal stamping quality assurance. Reliable suppliers can provide complete material certificates and test data, proving used materials meet specification requirements and final products have passed necessary quality inspections.

Through comprehensive application of advanced technology, professional talent, systematic methods, and continuous improvement, short-run metal stamping can achieve excellent quality control, providing high-precision, high-reliability metal components for various industry customers. This quality assurance capability not only meets current manufacturing needs but also lays the foundation for future more complex, more precise applications.

Material Diversity and Applications

In the field of short-run metal stamping, the diversity of material selection provides designers and engineers with tremendous creative space. Different metal materials possess unique physical, chemical, and mechanical properties that can meet specific requirements for various application scenarios. Understanding these material options and their applicability is crucial for optimizing product performance and cost. This section explores common material types, selection criteria, and surface treatment solutions in short-run metal stamping.

Common Metal Material Options

Short-run metal stamping can process a wide range of metal materials, from common carbon steel to specialty alloys, covering almost all stampable metals. This broad material adaptability enables it to meet various requirements from everyday consumer goods to high-end industrial applications.

Carbon steel is one of the most commonly used materials in short-run metal stamping, favored for its good formability, wide availability, and relatively low cost. From low-carbon to high-carbon steel, different carbon content provides different combinations of hardness, strength, and toughness suitable for various applications. For example, low-carbon steel is ideal for complex shapes requiring significant deformation, while high-carbon steel is suitable for components needing high strength and wear resistance.

Stainless steel is widely used in applications requiring corrosion resistance and aesthetic appearance. Austenitic stainless steels like 304 and 316 offer excellent formability and corrosion resistance, suitable for food processing equipment, medical devices, and architectural decoration. Martensitic stainless steels such as the 410 and 420 series provide higher strength and hardness, ideal for applications requiring wear resistance.

Aluminum alloys are favored in automotive, aviation, and electronics industries for their lightweight properties and good thermal conductivity. Common aluminum alloys like 6061 and 5052 offer good formability and moderate strength, suitable for most short-run stamping applications. Higher-strength 7075 aluminum alloy is used for more demanding aerospace components.

Copper and copper alloys, such as brass and bronze, are commonly used for electrical connectors, heat sinks, and decorative components due to their excellent electrical and thermal conductivity. These materials also offer good corrosion resistance and antimicrobial properties, giving them unique advantages in certain specialized applications.

Specialty alloys like titanium alloys, nickel-based alloys, and molybdenum alloys, while more expensive and difficult to process, perform excellently in extreme environments. These materials are typically used in aerospace, medical implants, and chemical equipment applications where short-run metal stamping provides an economically viable way to produce small batches of these high-value material components.

Material Properties and Application Scenario Matching

Selecting appropriate materials is one of the key factors for successful short-run metal stamping. This selection needs to comprehensively consider multiple factors, including mechanical performance requirements, environmental conditions, cost budgets, and manufacturing feasibility.

Strength-to-weight ratio is a key consideration in many applications. In automotive and aerospace fields, lightweight design can significantly improve fuel efficiency and performance. Materials like high-strength steel, aluminum alloys, and titanium alloys can maintain sufficient strength while reducing component weight. Short-run metal stamping allows engineers to test these materials' performance in small-batch production, optimizing design solutions.

Corrosion resistance is crucial in many application environments. Components exposed to moisture, salt spray, or chemicals need materials with appropriate corrosion resistance. Stainless steel, aluminum alloys, and certain specialty alloys excel in this aspect. Short-run metal stamping enables businesses to select the most suitable materials for specific environmental conditions without compromising for high-volume production economics.

Electrical and thermal properties are equally important for certain applications. Conductive components typically choose copper or aluminum materials, while applications requiring thermal isolation might select stainless steel or titanium alloys. Short-run metal stamping can precisely control the forming process of these materials, ensuring final products maintain required electrical or thermal properties.

Cost considerations cannot be overlooked in material selection. While certain high-performance materials might offer ideal technical characteristics, their high cost may strain project budgets. The advantage of short-run metal stamping is that it allows high-value materials to be used in small-batch production without significantly increasing overall project costs.

Manufacturing feasibility is also an important factor in material selection. Different materials have different forming characteristics, springback behaviors, and tool wear impacts. Experienced short-run metal stamping suppliers can provide valuable advice on material machinability, helping customers find balance points between performance requirements and manufacturing difficulties.

Surface Treatment and Aesthetic-Functional Balance

The material diversity in short-run metal stamping is reflected not only in base material selection but also in various surface treatment and post-processing options. These treatments can enhance product aesthetics and improve functionality and durability.

Electroplating is a common surface treatment method that deposits a thin metal coating on the metal surface. Processes like zinc, chrome, nickel, and gold plating provide different appearance effects while enhancing corrosion resistance, conductivity, or wear resistance. Short-run metal stamped parts typically have good surface quality, providing an ideal foundation for subsequent electroplating processes.

Anodizing is primarily used for aluminum alloy components, forming a dense oxide film on the surface. This treatment not only improves corrosion resistance but can also achieve various color effects through dyeing. In applications like electronic product casings and architectural decorative parts, anodized short-run stamped aluminum components are both attractive and durable.

Powder coating provides an environmentally friendly and durable surface treatment option. This method sprays electrically charged powder particles onto the metal surface, then heats them to melt and form a uniform coating. Powder coating can achieve rich color and texture effects while providing excellent corrosion and wear resistance. The precise dimensions and consistency of short-run metal stamped parts make them particularly suitable for high-quality powder coating treatment.

Mechanical surface treatments such as sandblasting, polishing, and brushing can create various surface textures and luster effects. These treatments not only meet aesthetic needs but also affect component tactile feel, light reflection characteristics, and friction coefficients. The flexibility of short-run metal stamping allows customers to experiment with different surface treatment effects in small-batch production, finding the most suitable solution for their application.

Laser marking and etching are precise methods for adding identification, serial numbers, or decorative patterns to short-run metal stamped parts. These techniques can create lasting and clear markings without affecting the basic material properties. These marking methods are particularly important in applications requiring traceability or brand identification.

By comprehensively considering base material properties and surface treatment options, short-run metal stamping can provide almost unlimited material solutions, meeting functional and aesthetic needs for various applications. This material diversity, combined with the flexibility and precision of short-run stamping, makes it an ideal manufacturing method from concept validation to small-batch production.

Conclusion

Comprehensive Value of Short-Run Metal Stamping

Short-run metal stamping, as a flexible and efficient manufacturing process, offers unique value propositions for modern manufacturing. Through our in-depth exploration, we can clearly see that this process is not merely a simplified version of high-volume stamping, but a specialized manufacturing solution with its own characteristics and advantages.

From a cost-effectiveness perspective, short-run metal stamping breaks the limitations of traditional manufacturing where small-batch production is prohibitively expensive. By reducing initial tooling investment, shortening setup times, and optimizing material utilization, it makes small-batch production economically viable. This cost advantage enables businesses to respond more flexibly to market demands, avoiding the risks of overproduction and inventory accumulation.

In terms of time efficiency, the quick turnaround capability of short-run metal stamping is particularly notable. The shortened cycle from design to finished product allows businesses to accelerate product development processes and bring innovative concepts to market faster. In today's competitive business environment, this time advantage often translates into significant competitive advantages.

Quality and precision are other core values of short-run metal stamping. The combination of modern stamping technology and advanced quality control systems ensures high precision and consistency even in small-batch production. This quality assurance is particularly important for high-requirement industries such as aerospace and medical devices.

Customization capabilities and design flexibility make short-run metal stamping an ideal tool for product development and innovation. It allows designers and engineers to freely explore different concepts, quickly validate designs, and make iterative improvements based on feedback. This flexibility not only accelerates the innovation process but also enhances the quality and market adaptability of final products.

Material diversity further expands the application range of short-run metal stamping. From common carbon steel and aluminum alloys to specialized high-performance alloys, almost all stampable metal materials can be processed through this technique. This broad material adaptability enables businesses to select the most suitable materials based on specific application requirements without compromising to meet manufacturing limitations.

Combining these advantages, short-run metal stamping provides manufacturing businesses with a solution that balances cost, time, quality, and flexibility. It fills the gap between prototype creation and mass production, offering more choices and possibilities for businesses of all sizes.

Recommendations for Selecting Suitable Suppliers

When deciding to utilize short-run metal stamping services, selecting the right supplier is key to success. The following recommendations can help manufacturing procurement personnel and engineers make informed choices:

First, evaluate the supplier's technical capabilities and equipment level. Advanced stamping equipment, CAD/CAM systems, and quality control tools form the foundation of high-quality short-run stamping. Suppliers should be able to demonstrate their equipment inventory and technical specifications, explaining how these capabilities meet your specific needs.

Second, examine the supplier's industry experience and expertise. Experienced suppliers typically better understand specific industry requirements and challenges, providing more valuable advice and solutions. Reviewing the supplier's project cases and customer recommendations, especially those related to your industry, can help assess their professional level.

Quality certification and standards compliance is another important consideration factor. Based on your industry requirements, look for suppliers with relevant certifications such as ISO 9001, IATF 16949, or AS9100. These certifications indicate the supplier has established systematic quality management processes capable of consistently delivering standard-compliant products.

Supply chain stability and delivery capability cannot be overlooked. Assess the supplier's production capacity, delivery record, and contingency plans to ensure they can deliver compliant products on time. Especially in the current environment where global supply chains face challenges, supplier reliability becomes increasingly important.

Communication and collaboration abilities form the foundation of successful partnerships. Excellent short-run metal stamping suppliers should understand your requirements, provide professional advice, and maintain transparent and effective communication. Establishing good collaborative relationships with suppliers in early project stages can avoid later misunderstandings and problems.

Finally, consider the supplier's value proposition rather than focusing solely on price. The lowest quote is not always the best choice, especially when quality, delivery, and service might be affected. Evaluate the total cost of ownership, including factors like quality, delivery, service, and long-term cooperation potential, to make comprehensive decisions.

Future Development Trends Outlook

As a manufacturing process, short-run metal stamping continues to evolve with technological advances and changing market demands. Understanding these trends can help businesses prepare and seize future opportunities.

Digitalization and intelligent manufacturing represent important development directions for short-run metal stamping. The application of Industry 4.0 concepts makes stamping equipment more intelligent, capable of collecting and analyzing production data, achieving predictive maintenance and automated quality control. These technologies not only improve production efficiency and quality consistency but also reduce dependence on skilled operators.

Advances in materials science will further expand the application range of short-run metal stamping. The development of new high-strength lightweight materials, specialty alloys, and composite materials brings new possibilities and challenges to stamping processes. Stamping technologies and tools adapting to these new materials continue to innovate, making more complex component designs possible.

Sustainable manufacturing concepts are influencing the development direction of short-run metal stamping. Reducing material waste, optimizing energy use, and adopting environmentally friendly surface treatment methods have become industry focus points. The high material utilization rate and on-demand production characteristics of short-run metal stamping make it an ideal choice for sustainable manufacturing strategies.

Supply chain localization trends may create more opportunities for short-run metal stamping. Global supply chain disruptions and geopolitical factors prompt businesses to reconsider their manufacturing and procurement strategies, focusing more on local or regional suppliers. The flexibility and small-batch production capability of short-run metal stamping make it particularly suitable for this localized production model.

The rise of hybrid manufacturing methods is also worth noting. The combination of short-run metal stamping with other manufacturing technologies (such as additive manufacturing, laser cutting, or CNC machining) can create more complex, higher-performance components. This hybrid approach leverages the advantages of various processes, providing designers and engineers with more possibilities.

As these trends develop, short-run metal stamping will continue to evolve and adapt, providing more innovation and value for manufacturing. Businesses should closely monitor these developments, keep pace with the times, and fully utilize the advantages of short-run metal stamping to maintain leading positions in competitive markets.

In conclusion, short-run metal stamping, as a flexible, precise, and economical manufacturing process, provides valuable solutions for modern manufacturing. By understanding its advantages, applicability, and development trends, manufacturing professionals can better utilize this process to achieve product innovation and business growth. Whether for product development, small-batch production, or market testing, short-run metal stamping can provide high-quality solutions meeting requirements.

Contact Us

📧 Email us: [email protected]

🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.