Advanced Plastic Parts Manufacturing: Innovations and Best Practices in 2025

Table of Contents

- Top Welding Components of 2025: Enhancing Safety and Efficiency in Welding Operations

- Advanced Auto-Darkening Helmet Technologies

- Ergonomic Welding Torches and Handles

- Enhanced Lens Technologies

- Innovative Welding Accessories

- Material Durability Advancements

- Safety Enhancements and Standards

- Conclusion

Introduction

The landscape of plastic manufacturing has undergone remarkable transformation in recent years, with 2025 marking a pivotal moment in the industry's evolution. As global demands for higher performance, sustainability, and cost-effectiveness continue to rise, manufacturers have responded with unprecedented innovations across the entire production spectrum. Today's plastic parts manufacturing represents a sophisticated blend of traditional expertise and cutting-edge technology, creating opportunities that were unimaginable just a decade ago.

Plastic components remain fundamental building blocks across virtually every industry sector—from automotive and aerospace to medical devices and consumer electronics. Their versatility, durability, and adaptability have cemented plastics as irreplaceable materials in modern manufacturing. However, what has changed dramatically is how these materials are processed, designed, and integrated into final products. The manufacturing methodologies of 2025 bear little resemblance to their predecessors, having been transformed through digitalization, automation, and materials science breakthroughs.

The journey to current manufacturing capabilities has been marked by several significant developments. Traditional processes like injection molding and CNC machining have been revolutionized through smart systems and predictive technologies. Meanwhile, additive manufacturing has matured from a prototyping tool into a legitimate production method for end-use parts. Perhaps most notably, the industry has embraced sustainability not merely as a regulatory requirement but as a core business strategy, driving innovations in materials, process efficiency, and waste reduction.

This article explores the cutting-edge advancements and best practices defining plastic parts manufacturing in 2025. We'll examine how technologies like injection molding, thermoforming, CNC machining, and 3D printing have evolved to meet contemporary challenges. Additionally, we'll investigate the critical considerations in material selection, design optimization, quality control, and sustainability initiatives that are reshaping the industry. Whether you're an engineer seeking to leverage the latest manufacturing capabilities or a procurement professional evaluating production options, this comprehensive overview will provide valuable insights into maximizing efficiency, sustainability, and product performance in today's dynamic manufacturing environment.

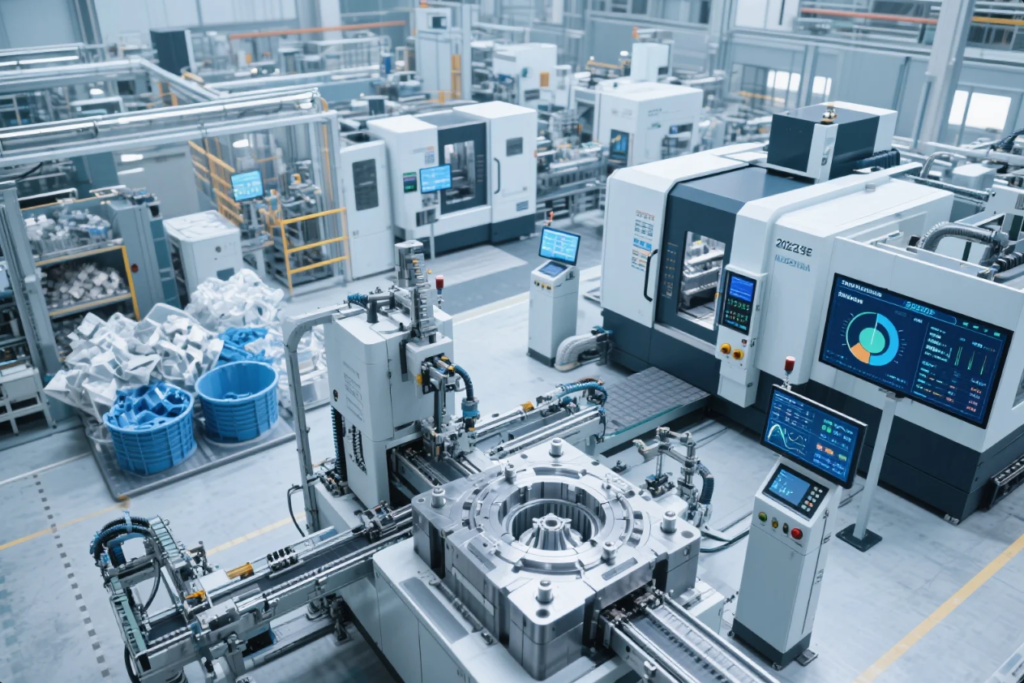

Current Landscape of Plastic Manufacturing in 2025

The plastic manufacturing industry in 2025 stands at a fascinating intersection of technological innovation, environmental responsibility, and economic pragmatism. Global market analyses indicate that the sector has experienced a compound annual growth rate of 4.7% since 2022, reaching a valuation of approximately $721 billion. This growth persists despite—or perhaps because of—significant transformations in how manufacturers approach production methodologies, material selection, and sustainability initiatives.

One of the most pronounced shifts in the industry has been the accelerated adoption of digital manufacturing ecosystems. Today's leading plastic parts producers operate facilities where virtually every aspect of production generates data that feeds into sophisticated analytics platforms. These interconnected systems enable unprecedented levels of process optimization, predictive maintenance, and quality assurance. The concept of the "smart factory" has evolved from aspirational marketing terminology to operational reality, with an estimated 67% of mid-to-large scale plastic manufacturers implementing comprehensive digital transformation strategies.

Sustainability has transcended its former status as a secondary consideration to become a fundamental driver of innovation across the plastic manufacturing landscape. This paradigm shift stems from a combination of regulatory pressures, consumer demands, and genuine corporate commitment to environmental stewardship. The European Circular Plastics Alliance's 2024 framework, along with similar initiatives in North America and Asia-Pacific regions, has established ambitious benchmarks for recycled content utilization, carbon footprint reduction, and end-of-life product management. Manufacturers have responded with remarkable ingenuity, developing closed-loop production systems that minimize waste while maintaining or even enhancing product performance.

The workforce supporting plastic manufacturing has likewise undergone significant evolution. The stereotype of low-skilled assembly line workers has given way to a reality of highly trained technicians managing sophisticated equipment and software systems. This transition has created both challenges and opportunities—while manufacturers struggle with skills gaps in emerging technologies, they also benefit from unprecedented capabilities in process control and quality assurance. Educational institutions and industry associations have responded with specialized training programs focused on advanced manufacturing technologies, helping to cultivate the multidisciplinary expertise required in modern production environments.

Despite these positive developments, the industry continues to face substantial challenges. Supply chain vulnerabilities exposed during the global disruptions of the early 2020s have prompted manufacturers to pursue greater resilience through strategies like nearshoring, vertical integration, and alternative material qualification. Meanwhile, volatile raw material costs and energy prices have intensified the focus on process efficiency and waste reduction. Perhaps most significantly, manufacturers must navigate an increasingly complex regulatory landscape governing everything from chemical composition to carbon emissions, requiring sophisticated compliance management systems and proactive engagement with policymakers.

The competitive dynamics within the industry have also evolved considerably. Traditional barriers to entry have been simultaneously reinforced by the capital requirements of advanced manufacturing technologies and eroded by the democratizing effects of digital design tools and flexible production methods. This has created a more diverse competitive ecosystem where specialized niche players can thrive alongside traditional manufacturing giants. Strategic partnerships and collaborative innovation networks have become increasingly common, allowing organizations to share development costs and leverage complementary capabilities.

As we examine the specific manufacturing processes and technologies in subsequent sections, it's important to recognize that these developments occur within this broader context of digital transformation, sustainability imperatives, workforce evolution, and shifting competitive dynamics. The most successful manufacturers in 2025 are those who effectively integrate technological innovations with strategic vision and organizational agility.

Material Selection: Advanced Polymers and Composites

The evolution of plastic materials has been nothing short of revolutionary in recent years, with 2025 representing a pinnacle of innovation in polymer science and engineering. Today's material selection process extends far beyond simply choosing between ABS and polycarbonate—it involves navigating a complex landscape of advanced formulations, specialized additives, and engineered composites that offer unprecedented combinations of properties and performance characteristics.

High-performance engineering plastics have experienced remarkable advancement, with materials like polyetheretherketone (PEEK), polyetherimide (PEI), and polyphenylene sulfide (PPS) becoming increasingly accessible for mainstream applications. These materials, once reserved exclusively for aerospace and specialized industrial uses due to their cost and processing challenges, have benefited from manufacturing innovations that have expanded their applicability. For instance, the development of optimized injection molding parameters and advanced mold temperature control systems has reduced processing difficulties, while economies of scale have gradually improved cost competitiveness. The result is a new generation of consumer and industrial products that benefit from exceptional thermal stability, chemical resistance, and mechanical properties previously unattainable in mass-produced plastic components.

Perhaps the most significant development in materials science has been the maturation of sustainable and bio-based polymers. The early generations of these materials often presented manufacturers with difficult tradeoffs between environmental benefits and performance limitations. In 2025, however, advanced bio-based polymers derived from agricultural waste streams, algae, and atmospheric carbon capture offer properties rivaling or even exceeding their petroleum-based counterparts. Companies like NatureWorks and Avantium have pioneered commercial-scale production of high-performance PLA (polylactic acid) and PEF (polyethylene furanoate) variants that maintain their mechanical properties across a much wider temperature range than earlier formulations. Meanwhile, enhanced biodegradability mechanisms ensure these materials decompose predictably in industrial composting facilities without compromising shelf life during normal use.

Composite materials represent another frontier that has transformed plastic manufacturing capabilities. Fiber-reinforced plastics incorporating carbon, glass, or natural fibers have long offered enhanced strength-to-weight ratios, but recent innovations have addressed historical limitations in processing efficiency and recyclability. Thermoplastic composites using discontinuous fiber reinforcement can now be processed using modified injection molding equipment, dramatically reducing production cycle times compared to traditional thermoset composites. Additionally, chemical recycling technologies have evolved to efficiently separate and recover both the polymer matrix and reinforcing fibers, addressing previous end-of-life challenges.

Smart materials with embedded functionality constitute perhaps the most exciting development in the polymer landscape. These include thermochromic polymers that change color in response to temperature fluctuations, self-healing materials that can repair minor damage autonomously, and conductive plastics that enable electronic functionality without metal components. While these materials were laboratory curiosities just a few years ago, they have now entered commercial production for applications ranging from consumer electronics to medical devices. For example, Covestro's self-healing polycarbonate blends are being used in high-end smartphone cases, while DuPont's stretchable electronic materials are finding applications in wearable health monitoring devices.

The selection criteria for these advanced materials have become correspondingly sophisticated. Engineers must now consider not only traditional factors like mechanical properties and chemical resistance but also sustainability metrics, supply chain resilience, and end-of-life scenarios. This complexity has driven the development of advanced material selection software that incorporates multi-criteria decision analysis algorithms to help engineers navigate these tradeoffs efficiently. These tools integrate with CAD systems and simulation software to provide real-time feedback on material choices during the design process.

For manufacturers, staying current with these material innovations requires ongoing education and partnership with material suppliers. The most successful organizations have established dedicated materials engineering teams that continuously evaluate emerging options and develop application-specific expertise. These teams work closely with design engineers to ensure that material selection decisions optimize both product performance and manufacturing efficiency. As material options continue to proliferate, this specialized knowledge becomes an increasingly valuable competitive advantage.

Injection Molding: Technological Advancements

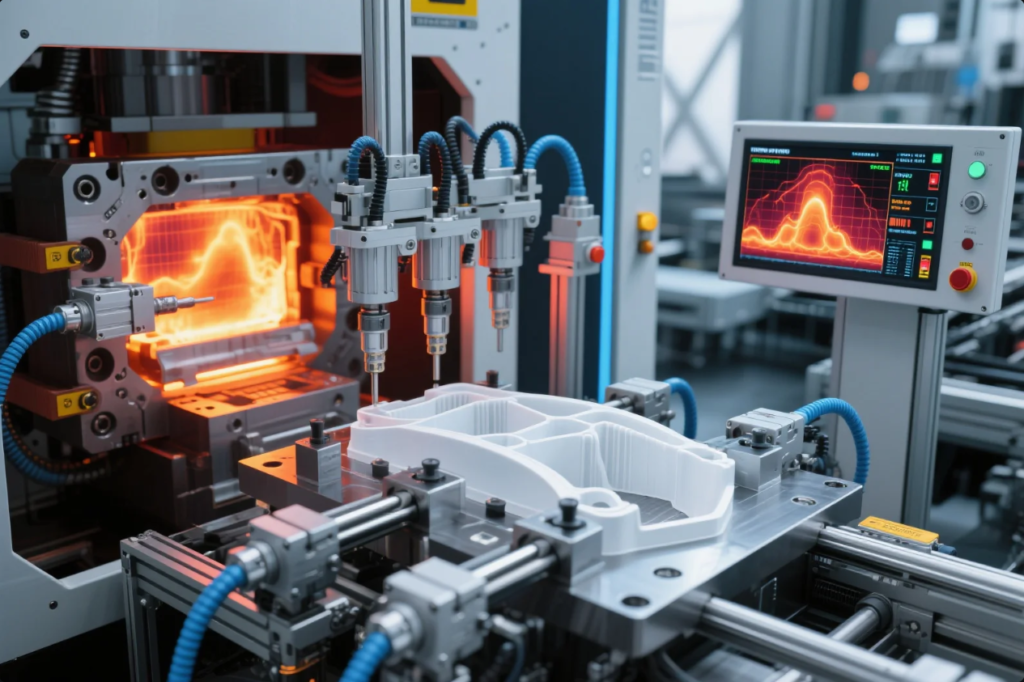

Injection molding remains the cornerstone of high-volume plastic manufacturing in 2025, but today's process bears little resemblance to its predecessors. The fundamental principle—injecting molten plastic into a mold cavity—may be unchanged, but virtually every aspect of the technology has been transformed through digitalization, automation, and materials science innovations. These advancements have dramatically expanded the capabilities of injection molding while simultaneously addressing historical challenges related to efficiency, consistency, and sustainability.

Smart injection molding systems represent perhaps the most significant evolution in the field. Modern machines incorporate extensive sensor networks that monitor dozens of process parameters in real-time, including melt temperature profiles, injection pressure curves, cooling rates, and even mold cavity gas evacuation. These sensors feed data into sophisticated control systems that can make microsecond adjustments to process parameters, maintaining optimal conditions throughout the production cycle. The result is unprecedented consistency in part quality, with some manufacturers reporting defect rate reductions exceeding 85% compared to traditional systems. Companies like Arburg and Engel have pioneered these intelligent systems, integrating machine learning algorithms that continuously optimize process parameters based on historical performance data and current operating conditions.

The capabilities of injection molding have expanded dramatically through innovations in multi-material and micro-molding technologies. Multi-material injection systems can now seamlessly combine up to six different polymers in a single molding cycle, creating complex components with varying mechanical properties, colors, and textures without secondary assembly operations. This capability has revolutionized product design across industries, from consumer electronics with integrated soft-touch interfaces to medical devices with precisely controlled drug-eluting components. Meanwhile, micro-molding technologies have pushed the boundaries of miniaturization, with systems capable of producing components with features measured in microns and tolerances of ±0.001mm. These advancements have been particularly transformative in medical device manufacturing, enabling the production of complex components for minimally invasive surgical tools and implantable devices.

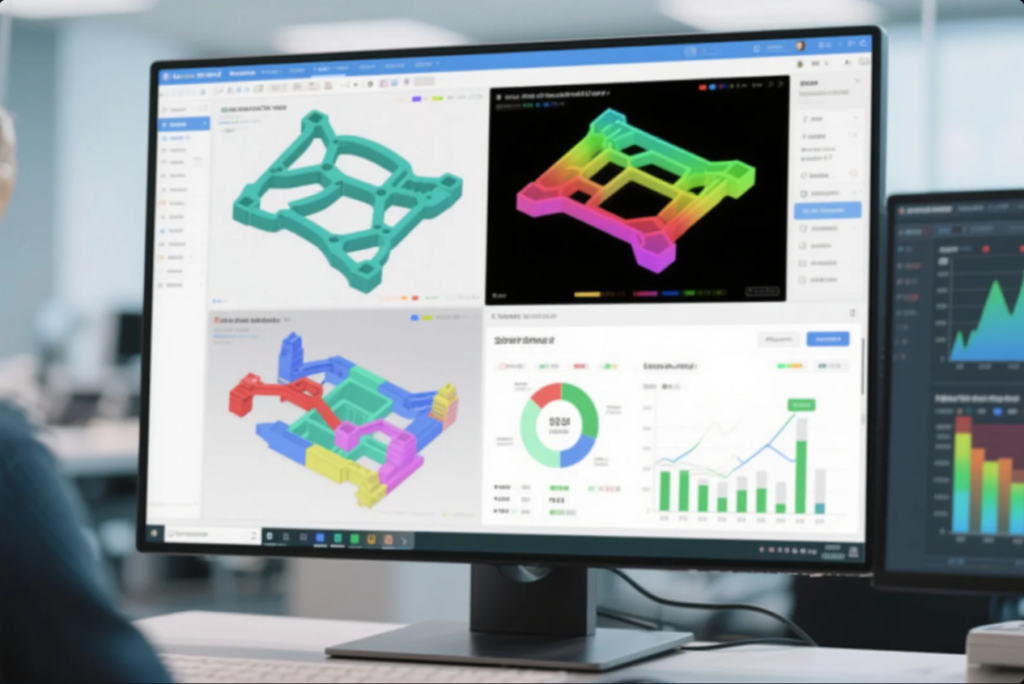

Simulation and predictive modeling have fundamentally changed how injection molded parts are designed and how molding processes are developed. Advanced CAE (Computer-Aided Engineering) software can now accurately predict how polymers will flow and solidify within complex mold geometries, accounting for variables like fiber orientation in composites, shrinkage compensation, and residual stress distribution. These simulations have moved beyond the engineering department to become integral to the production floor, with digital twins of molding processes running in parallel with physical production. When deviations between simulated and actual performance occur, machine learning algorithms analyze the discrepancies and refine the simulation models, creating a continuous improvement loop that progressively enhances predictive accuracy.

Energy efficiency has become a central focus in injection molding technology development, driven by both environmental concerns and economic pressures. The latest generation of all-electric injection molding machines consumes up to 70% less energy than hydraulic systems while offering superior precision and repeatability. Advanced heat recovery systems capture thermal energy from cooling processes and redirect it for material drying or facility heating. Even mold design has been reimagined through the lens of energy efficiency, with conformal cooling channels created through additive manufacturing techniques providing more uniform temperature control while reducing cooling time and energy consumption. These improvements collectively represent not only significant cost savings but also substantial reductions in the carbon footprint of injection molded components.

Quality control in injection molding has been transformed through the integration of advanced inspection technologies directly into the production line. Computer vision systems equipped with deep learning algorithms can inspect 100% of produced parts in real-time, detecting surface defects, dimensional variations, and even internal flaws through technologies like embedded infrared sensors. When potential issues are identified, the system can automatically adjust process parameters to correct developing problems before they result in defective parts. This approach represents a paradigm shift from statistical quality control to comprehensive, adaptive process control that virtually eliminates the production of non-conforming components.

A case study from the medical device industry illustrates the transformative impact of these technologies. A leading manufacturer of insulin delivery systems recently transitioned production of a critical component from traditional injection molding to a fully integrated smart molding cell. The new system combines multi-material capability for creating a rigid housing with soft-touch interface elements, in-mold assembly of precision mechanical components, and 100% inline inspection. The result was a 43% reduction in production cost, 67% decrease in energy consumption, and near-zero defect rates—all while producing a more complex component than was previously possible. This example demonstrates how modern injection molding has evolved from a simple manufacturing process into an integrated production ecosystem that delivers unprecedented value across multiple dimensions.

CNC Machining for Plastics: Precision and Efficiency

CNC machining has undergone a remarkable evolution in plastic parts manufacturing, transforming from a primarily metal-focused technology into a sophisticated solution for creating high-precision plastic components. In 2025, this subtractive manufacturing process offers unprecedented capabilities for producing complex geometries with exceptional dimensional accuracy and surface finishes that rival or exceed those achieved through traditional molding processes. The advancements in CNC technology specifically optimized for plastics have expanded its role beyond prototyping and low-volume production into a versatile manufacturing solution across diverse applications.

High-speed machining developments have dramatically improved the economics and capabilities of CNC processing for plastic materials. Modern CNC systems dedicated to plastics operate at spindle speeds exceeding 60,000 RPM—significantly higher than those used for metals—allowing for faster material removal rates while maintaining excellent surface quality. These high-speed systems utilize specialized cutting tools with geometries specifically designed for various polymer types, addressing historical challenges like melting, burring, and stress whitening that often occurred when machining plastics with conventional tooling. The combination of optimized cutting parameters and polymer-specific tooling has reduced cycle times by up to 70% compared to traditional approaches, making CNC machining increasingly competitive for medium-volume production runs.

Tool path optimization has been revolutionized through advanced CAM (Computer-Aided Manufacturing) software incorporating physics-based modeling of polymer cutting mechanics. These sophisticated algorithms consider the unique characteristics of different plastic materials—such as thermal conductivity, elasticity, and chip formation behavior—to generate optimal cutting strategies. Adaptive toolpaths automatically adjust feed rates and cutting depths based on the changing geometry of the workpiece, maintaining ideal cutting conditions throughout the machining process. Some systems even incorporate real-time monitoring that detects tool wear or material anomalies, making instantaneous adjustments to preserve part quality. These intelligent machining strategies have dramatically improved both productivity and consistency in plastic part production.

Surface finish capabilities have seen particularly impressive advancements, with modern CNC systems achieving optical-quality surfaces directly from the machining process. This eliminates the need for secondary finishing operations that were once standard practice for machined plastic components. Multi-axis machining centers with continuous 5-axis capability can maintain optimal tool orientation relative to the part surface throughout complex geometries, producing consistent surface characteristics even on intricate contoured features. For applications requiring exceptional aesthetics, specialized vibration dampening technologies and advanced spindle designs minimize tool marks and chatter, achieving surface roughness measurements below 0.2 μm Ra—comparable to polished injection molded parts.

The integration of in-process measurement systems represents another significant advancement in CNC machining for plastics. These systems use various technologies—including touch probes, laser scanning, and machine vision—to verify critical dimensions during the machining process. When deviations are detected, the control system can automatically compensate through tool offset adjustments or adaptive machining strategies. This capability is particularly valuable for plastic components, as it accounts for material-specific behaviors like springback and dimensional changes due to moisture absorption or thermal effects. The result is unprecedented dimensional accuracy, with some manufacturers routinely achieving tolerances of ±0.01mm on complex plastic components.

Environmental control has emerged as a critical aspect of high-precision plastic machining. Temperature-controlled machining environments maintain consistent material properties throughout the production process, while sophisticated chip evacuation systems prevent heat buildup that could distort delicate features. Dry machining techniques have largely replaced traditional coolants for most plastic applications, eliminating chemical compatibility concerns while reducing environmental impact. For materials that do require cooling during machining, specialized micro-mist systems deliver precisely controlled amounts of compatible cooling agents exactly where needed, minimizing both consumption and waste.

The aerospace industry provides a compelling case study of CNC machining's evolution for plastic components. A leading aircraft manufacturer recently transitioned production of complex interior cabin components from traditional thermoforming to 5-axis CNC machining of engineering-grade thermoplastics. The switch enabled the integration of multiple features—including mounting points, wire routing channels, and snap-fit connections—into single components that previously required assembly from multiple parts. Despite the higher per-part processing cost compared to high-volume molding processes, the elimination of expensive tooling, reduced assembly labor, and improved inventory management yielded a 28% reduction in total production cost. Moreover, the digital manufacturing approach allowed for rapid design iterations and customization options that would have been economically prohibitive with traditional tooling-based methods.

As CNC machining technology continues to advance, its role in plastic parts manufacturing will likely expand further, particularly for applications requiring exceptional precision, complex geometries, or material properties that are difficult to achieve through molding processes. The technology offers a compelling combination of quality, flexibility, and increasingly competitive economics that makes it an essential component of the modern plastic manufacturing toolkit.

Thermoforming and Vacuum Forming: New Capabilities

Thermoforming and vacuum forming technologies have experienced a remarkable renaissance in recent years, evolving from relatively simple processes into sophisticated manufacturing methods capable of producing complex, high-precision plastic components. In 2025, these forming technologies offer compelling advantages in terms of cost-effectiveness, design flexibility, and sustainability that have expanded their application across numerous industries. The integration of advanced control systems, innovative tooling approaches, and novel material developments has elevated thermoforming from its traditional packaging focus into a versatile solution for producing everything from medical device components to architectural elements.

Temperature control precision represents one of the most significant advancements in modern thermoforming equipment. Traditional systems often struggled with uneven heating that resulted in inconsistent material distribution and unpredictable shrinkage. Today's advanced thermoforming systems employ zoned ceramic heaters with individual PID controllers that create precisely tailored heating profiles across the entire sheet surface. Infrared thermography cameras continuously monitor the temperature distribution in real-time, while AI-driven control systems make microsecond adjustments to maintain optimal forming conditions. This level of thermal precision enables the consistent processing of advanced materials like PEEK, PEI, and fiber-reinforced composites that were historically challenging to thermoform due to their narrow processing windows.

The integration of 3D printed molds has revolutionized the economics and capabilities of thermoforming for low-to-medium volume production runs. Traditionally, thermoform tooling required expensive and time-consuming CNC machining of aluminum molds, making the process economically viable only for higher production volumes. The emergence of high-temperature resistant photopolymers and composite materials for additive manufacturing has enabled the rapid production of durable thermoforming molds at a fraction of the traditional cost. These 3D printed tools can incorporate complex cooling channels, vacuum distribution networks, and even embedded sensors that would be impossible to create through conventional machining. For production volumes under 10,000 units, this approach typically reduces tooling costs by 60-80% while shortening lead times from weeks to days.

Material distribution control has seen remarkable improvements through both process innovations and simulation-driven design. Plug-assist systems, which help distribute material before vacuum application, have evolved from simple geometric shapes to complex, multi-stage mechanisms that precisely control material flow during the forming process. These systems are now designed using advanced simulation software that predicts how specific polymer sheets will stretch and thin during forming, allowing engineers to optimize plug geometry and movement patterns for ideal material distribution. Some advanced systems even employ servo-driven, multi-axis plug assists that follow complex motion paths, ensuring uniform wall thickness across intricate geometries that would have been impossible to form consistently with previous technologies.

The automation of thermoforming processes has progressed dramatically, transforming what was often a labor-intensive operation into a highly efficient, repeatable manufacturing method. Modern thermoforming lines incorporate robotic sheet loading, precision registration systems, and automated trimming operations that maintain tight tolerances while minimizing human intervention. In-line inspection systems using machine vision technology verify critical dimensions and detect quality issues in real-time, enabling immediate process adjustments. These automation advances have not only improved consistency and reduced labor costs but have also enabled thermoforming to achieve tolerances approaching those of injection molding for many applications—typically ±0.1mm for features across a formed part.

Sustainability considerations have driven significant innovations in thermoforming processes and materials. Energy consumption has been reduced through improved heater efficiency, better insulation, and heat recovery systems that capture and reuse thermal energy. Material utilization has improved through optimized sheet sizing, scrap reduction strategies, and closed-loop recycling systems that reprocess trimmed material directly back into new sheets. The process is particularly well-suited for working with recycled and bio-based polymers, as it subjects the material to less intense thermal and mechanical stress compared to injection molding. Several manufacturers have developed specialized thermoforming grades of sustainable materials that offer enhanced processing characteristics while maintaining their environmental benefits.

A compelling case study from the sustainable packaging sector illustrates these advancements in action. A leading food service provider recently transitioned from traditional polystyrene food containers to a new generation of thermoformed packaging using a composite sheet made from agricultural waste fibers and biodegradable polymers. The manufacturing process employs 3D printed molds with conformal cooling channels, precision zoned heating, and an AI-controlled forming sequence optimized specifically for the unique material characteristics. The resulting containers offer comparable performance to traditional products but decompose completely in industrial composting facilities within 90 days. Despite the advanced technology employed, the manufacturing cost remains competitive with conventional methods due to material cost savings, energy efficiency improvements, and the elimination of secondary assembly operations.

As thermoforming technology continues to advance, its position as a versatile, cost-effective manufacturing solution for plastic components will likely strengthen further. The combination of reduced tooling costs, improved precision, design flexibility, and sustainability advantages makes it an increasingly attractive option for applications across diverse industries, particularly as manufacturers seek to balance economic and environmental considerations in their production strategies.

Additive Manufacturing/3D Printing Revolution

The landscape of additive manufacturing for plastic parts has undergone a profound transformation in 2025, evolving far beyond its origins as a prototyping technology to become a legitimate production method for end-use components across diverse industries. This revolution has been driven by simultaneous advances in printing technologies, materials science, process control, and design methodologies that collectively address historical limitations in speed, consistency, material properties, and cost-effectiveness. Today's additive manufacturing ecosystem offers capabilities that complement and, in some applications, surpass traditional production methods, creating new possibilities for product innovation and manufacturing efficiency.

Material diversity represents one of the most significant advancements in polymer-based additive manufacturing. The limited range of printable plastics that once constrained the technology's applications has expanded dramatically to include virtually every class of polymer used in traditional manufacturing. High-performance materials like PEEK, PEKK, and PEI (ULTEM) are now routinely processed through specialized fused filament fabrication (FFF) and powder bed fusion systems, producing components with mechanical and thermal properties suitable for demanding aerospace and automotive applications. Fiber-reinforced composites incorporating continuous carbon, glass, or aramid fibers can be precisely deposited to create parts with exceptional strength-to-weight ratios and directionally optimized properties. Even elastomeric materials with precisely controlled durometer values and resilience characteristics can be accurately produced through advanced material jetting and vat photopolymerization processes.

Multi-material printing capabilities have evolved from basic two-material combinations to sophisticated systems capable of seamlessly integrating multiple polymers with varying mechanical, optical, and electrical properties within a single build process. The latest generation of material jetting systems can deposit up to eight different materials simultaneously with micron-level precision, creating components with functionally graded properties that would be impossible to manufacture through traditional methods. These systems enable the production of complex assemblies as unified structures—incorporating rigid structural elements, flexible hinges, transparent windows, and even conductive pathways within a single printed part. This capability eliminates assembly operations, reduces part count, and enables entirely new approaches to product design that transcend the limitations of conventional manufacturing.

Production speed, historically a significant barrier to additive manufacturing's adoption for volume production, has improved by orders of magnitude through various technological innovations. High-speed sintering (HSS) systems use infrared lamps and digital light projection to selectively fuse entire layers of polymer powder simultaneously, rather than tracing each cross-section with a laser. Continuous liquid interface production (CLIP) technologies have eliminated the step-by-step nature of traditional layer-based printing, creating a continuous solidification process that produces parts up to 100 times faster than earlier systems. For large components, pellet-based extrusion systems with multiple deposition heads working in coordinated patterns have dramatically increased material throughput while reducing raw material costs by utilizing standard plastic pellets rather than specialized filaments.

Quality assurance in additive manufacturing has matured through the integration of comprehensive monitoring and control systems. Modern 3D printers incorporate multiple sensor arrays that monitor every aspect of the build process—from material feedstock characteristics to thermal conditions within the build chamber to the dimensional accuracy of each deposited layer. Machine learning algorithms analyze this data in real-time, identifying potential issues before they affect part quality and making automatic adjustments to process parameters. Some systems even incorporate in-situ metrology that compares the as-built geometry to the original design intent, enabling closed-loop control that ensures dimensional accuracy regardless of material behavior or environmental variations. These quality control advances have been crucial in establishing additive manufacturing as a trusted production method for critical applications in medical, aerospace, and automotive industries.

The integration of additive manufacturing with traditional production methods has created hybrid manufacturing approaches that leverage the strengths of each technology. For instance, complex internal features might be created through 3D printing, with external surfaces subsequently machined to achieve precise dimensions and superior surface finish. Injection molding inserts with conformal cooling channels produced through metal 3D printing are combined with conventionally manufactured mold bases to create hybrid tooling that dramatically improves cycle times and part quality. These integrated approaches recognize that additive manufacturing is not necessarily a replacement for traditional methods but rather a complementary technology that expands the overall capabilities of modern manufacturing operations.

A compelling case study from the consumer products sector illustrates the transformative impact of these advancements. A leading audio equipment manufacturer recently redesigned its premium headphone line to leverage the unique capabilities of advanced additive manufacturing. The new design integrates acoustically optimized sound chambers, precision-tuned resonators, and ergonomic fit elements into a unified structure that would require dozens of components if produced conventionally. Multi-material printing enables the seamless transition from rigid structural elements to soft-touch surfaces without assembly operations. The production process employs high-speed vat photopolymerization with in-situ monitoring and automated post-processing, achieving production rates and per-unit costs competitive with traditional manufacturing methods while eliminating assembly labor and reducing supply chain complexity. Perhaps most significantly, the design can be digitally customized for individual users based on 3D scans of their ear geometry, creating a personalized product experience that would be economically unfeasible through conventional manufacturing.

As additive manufacturing technologies continue to mature, their role in plastic parts production will undoubtedly expand further. The unique combination of design freedom, material flexibility, and digital manufacturing advantages positions 3D printing as an increasingly central element of modern manufacturing strategies, particularly for applications that value customization, complex geometries, or integrated functionality. While traditional manufacturing methods will remain essential for many applications, the boundaries between additive and conventional production continue to blur as manufacturers adopt more holistic, application-specific approaches to production technology selection.

Design Considerations for Modern Plastic Parts

The approach to designing plastic components has undergone a fundamental transformation in 2025, driven by advances in materials, manufacturing technologies, and computational tools. Modern design methodologies transcend traditional constraints, embracing a more holistic approach that considers the entire product lifecycle from initial concept through manufacturing to end-of-life scenarios. This evolution in design thinking has enabled unprecedented levels of functionality, efficiency, and sustainability in plastic parts across virtually every industry sector.

Design for manufacturability (DFM) principles have evolved significantly beyond basic guidelines for draft angles and uniform wall thicknesses. Today's DFM approaches are deeply integrated with specific manufacturing processes and material characteristics, supported by sophisticated simulation tools that provide immediate feedback on producibility. Advanced CAD systems now incorporate manufacturing intelligence modules that automatically evaluate designs against process-specific constraints in real-time as the designer works. These systems flag potential issues such as sink marks in injection molding, undercuts that would complicate tool design, or thin sections that might create flow problems—all while suggesting alternatives that maintain design intent while improving manufacturability. This integration of design and manufacturing considerations has dramatically reduced development cycles by eliminating iterative redesign loops that were once standard practice.

Topology optimization and generative design have revolutionized the structural efficiency of plastic components. Rather than beginning with a preconceived geometry that is subsequently analyzed and refined, these approaches start by defining the functional requirements, material properties, and manufacturing constraints, then algorithmically generate optimal structures that maximize performance while minimizing material usage. The resulting organic geometries often bear little resemblance to conventionally designed components but offer dramatic improvements in strength-to-weight ratios, material efficiency, and even aesthetic appeal. While these computational design methods were once limited to specialized applications due to manufacturing constraints, the maturation of additive manufacturing and advanced molding techniques has made such optimized structures practical for mainstream production. Companies across industries report material savings of 30-60% while maintaining or improving functional performance through these approaches.

Simulation-driven design has expanded far beyond basic structural analysis to encompass virtually every aspect of a component's performance and manufacturing. Multi-physics simulations can simultaneously evaluate structural integrity, thermal management, fluid interactions, electromagnetic compatibility, and acoustic performance—providing a comprehensive understanding of how a part will function in real-world conditions before any physical prototypes are created. For manufacturing processes, advanced simulation tools accurately predict how specific materials will behave during processing, accounting for phenomena like fiber orientation in composites, shrinkage and warpage in molding, or layer adhesion strength in additive manufacturing. These simulations have become increasingly accessible through cloud-based platforms that provide sophisticated analysis capabilities without requiring specialized hardware or extensive training, democratizing advanced design validation across organizations of all sizes.

Material-specific design guidelines have become increasingly sophisticated as the range of available polymers and composites has expanded. Design systems now incorporate extensive materials databases that provide not just basic mechanical properties but detailed information on processing characteristics, environmental performance, aging behavior, and compatibility with various manufacturing methods. These resources enable designers to make informed material selections based on comprehensive performance criteria rather than defaulting to familiar options. Furthermore, design tools can automatically adjust geometric features based on material-specific considerations—for example, modifying wall thickness transitions or reinforcement structures based on the flow characteristics and shrinkage behavior of a selected polymer. This integration of material science into the design process ensures that components fully leverage the unique properties of advanced materials while avoiding potential pitfalls.

Designing for sustainability has transcended superficial "green" initiatives to become a fundamental aspect of plastic component development. Modern design approaches consider the entire lifecycle environmental impact, from raw material sourcing through manufacturing, use phase, and end-of-life scenarios. Design tools now incorporate environmental impact assessment modules that quantify factors like carbon footprint, energy consumption, water usage, and potential toxicity across the product lifecycle. These assessments inform material selection, structural optimization, and manufacturing process choices to minimize environmental impact while maintaining performance requirements. Design for disassembly and recycling has become particularly important, with components increasingly designed for easy separation of different materials at end-of-life, improved recyclability, and in some cases, biodegradability in specific environments. These considerations are no longer afterthoughts but are integrated from the earliest conceptual stages of design.

The integration of electronics and functionality directly into plastic components represents another significant design trend. Advances in materials and manufacturing have enabled the embedding of sensors, circuitry, and even power generation capabilities within plastic structures, creating "smart" components that can monitor their own condition, communicate with other systems, or adapt to changing conditions. Design tools have evolved to support this convergence of mechanical, electrical, and software elements, enabling truly interdisciplinary product development. For example, designers can now simultaneously develop a component's physical structure and the layout of embedded conductive pathways, ensuring optimal integration and performance. This approach reduces assembly operations, improves reliability by eliminating connectors and interfaces, and enables entirely new product functionalities that were previously impractical.

As design methodologies continue to evolve, the most successful organizations are those that embrace a collaborative, multidisciplinary approach that breaks down traditional silos between design, materials science, manufacturing engineering, and sustainability. This integrated perspective, supported by increasingly sophisticated computational tools and manufacturing technologies, is enabling a new generation of plastic components that set new standards for performance, efficiency, and environmental responsibility.

Quality Control and Testing Innovations

Quality control in plastic parts manufacturing has evolved dramatically in 2025, transitioning from traditional statistical sampling approaches to comprehensive, real-time monitoring systems that ensure unprecedented levels of consistency and reliability. This transformation has been driven by advances in sensor technologies, machine vision systems, data analytics, and the integration of artificial intelligence throughout the production process. Modern quality control strategies now focus on preventing defects rather than merely detecting them, fundamentally changing the economics and capabilities of plastic manufacturing across industries.

Advanced inspection technologies have revolutionized how plastic parts are evaluated throughout the production cycle. Multi-spectral imaging systems can detect surface defects invisible to the human eye, including subtle variations in material composition, internal stress patterns, and even molecular orientation in crystalline polymers. Terahertz imaging enables non-destructive inspection of internal structures without the safety concerns associated with X-ray systems, identifying voids, inclusions, or delamination in multi-layer components. For critical applications, atomic force microscopy has moved from the laboratory to the production floor, providing nanometer-scale surface characterization that ensures components meet increasingly stringent requirements for applications like medical implants or semiconductor packaging. These technologies collectively enable 100% inspection of production parts rather than statistical sampling, dramatically reducing the risk of defective components reaching customers.

In-line monitoring systems have transformed quality assurance from a post-production activity to an integral part of the manufacturing process itself. Modern production equipment incorporates extensive sensor networks that continuously monitor critical parameters throughout the entire manufacturing cycle. In injection molding, for example, high-resolution pressure transducers embedded in mold cavities provide real-time data on material flow patterns and packing behavior, while thermal imaging cameras monitor temperature distribution across the part during cooling. Similar monitoring capabilities have been developed for virtually every plastic manufacturing process, from extrusion and blow molding to additive manufacturing and thermoforming. The data from these sensors is analyzed in real-time, with automated systems making immediate adjustments to process parameters when deviations from optimal conditions are detected, maintaining consistent quality without human intervention.

Non-destructive testing methods have advanced significantly, enabling thorough evaluation of critical components without sacrificing production output. Ultrasonic inspection systems can now create detailed three-dimensional maps of internal structures in plastic parts, identifying defects as small as 10 microns regardless of component geometry or material opacity. Laser shearography detects subtle deformations under controlled stress conditions, revealing potential structural weaknesses before they manifest as failures. For components with electrical or thermal functionality, automated test systems can verify performance characteristics while simultaneously conducting visual and dimensional inspections, ensuring that parts meet all specifications in a single evaluation step. These non-destructive approaches provide comprehensive quality assurance while eliminating the waste associated with traditional destructive testing methods.

Artificial intelligence has transformed defect detection and classification, achieving levels of accuracy and consistency that surpass human capabilities. Deep learning algorithms trained on vast datasets of defect images can instantly identify and categorize quality issues across diverse part geometries and material types. These systems continuously improve their detection capabilities through machine learning, becoming increasingly sensitive to subtle defects that might indicate emerging process issues. Beyond simple defect identification, advanced AI systems analyze patterns in quality data to identify root causes of problems, often detecting correlations between process parameters and quality outcomes that would be impossible for human operators to recognize. This predictive capability allows manufacturers to address potential issues before they result in defective parts, dramatically reducing scrap rates and production interruptions.

Traceability systems have evolved to provide comprehensive documentation of every aspect of a component's production history. Each part can now be uniquely identified through various marking technologies—from traditional barcodes to embedded RFID tags to chemical fingerprinting for the most critical applications. These identifiers link to digital records containing complete information about raw materials, process parameters, quality measurements, and test results throughout the production process. For regulated industries like medical devices and aerospace, these traceability systems automatically generate the documentation required for compliance, streamlining regulatory processes while ensuring complete accountability. Even for consumer products, enhanced traceability enables more effective quality management and facilitates targeted recalls if issues are discovered after distribution.

A case study from the automotive industry illustrates the transformative impact of these quality control innovations. A tier-one supplier of safety-critical plastic components recently implemented a comprehensive quality system incorporating in-mold sensors, multi-spectral imaging, and AI-driven process control across their injection molding operations. The system continuously monitors 42 distinct process parameters and performs 100% inspection of produced parts against 18 quality criteria. When potential issues are detected, the system automatically adjusts process parameters to maintain quality, while an AI module analyzes patterns to identify root causes and recommend preventive actions. The results have been remarkable: defect rates reduced by 99.7%, customer returns virtually eliminated, and overall production efficiency improved by 28% due to reduced scrap and downtime. Perhaps most significantly, the enhanced quality assurance has enabled the supplier to expand into higher-value applications with more stringent requirements, creating new business opportunities while reducing quality-related costs.

As quality control technologies continue to advance, the distinction between manufacturing and quality assurance is increasingly blurring. The future of plastic parts production lies in intelligent, self-regulating manufacturing systems that inherently produce consistent quality rather than relying on separate inspection processes to filter out defects. This integrated approach not only improves product reliability but also enhances overall manufacturing efficiency and sustainability by minimizing waste and optimizing resource utilization.

Sustainability Initiatives in Plastic Manufacturing

Sustainability has evolved from a peripheral concern to a central driving force in plastic manufacturing by 2025. This transformation reflects both external pressures—including regulatory requirements, consumer expectations, and investor priorities—and internal recognition of the business value inherent in more sustainable operations. Today's leading manufacturers have moved beyond superficial "green" marketing to implement comprehensive sustainability strategies that address environmental impacts throughout the entire product lifecycle, from raw material sourcing to end-of-life management.

Closed-loop manufacturing systems represent perhaps the most significant advancement in sustainable plastic production. These sophisticated approaches integrate production waste recovery, post-consumer recycling, and remanufacturing capabilities into unified systems that minimize virgin material consumption and waste generation. Advanced sorting technologies employing AI-powered optical recognition can now identify and separate dozens of different polymer types with near-perfect accuracy, even from mixed waste streams. Chemical recycling processes have matured to complement mechanical recycling, enabling the recovery of high-quality base polymers from contaminated or degraded materials that were previously unrecyclable. Some manufacturers have achieved remarkable circularity metrics, with facilities operating at over 90% closed-loop efficiency—meaning less than 10% of their material inputs come from virgin sources, with the remainder derived from recovered production scrap and post-consumer waste.

Material recovery technologies have advanced dramatically, enabling the reclamation of high-value polymers from increasingly challenging waste streams. Solvent-based purification systems can selectively dissolve target polymers from mixed plastic waste, removing contaminants at the molecular level before reprecipitating the purified material. Enzymatic depolymerization processes developed through synthetic biology research can break specific polymers down into their monomer building blocks, which are then repolymerized into virgin-equivalent materials. These technologies are particularly valuable for recovering engineering plastics and specialty polymers that retain significant economic value even after their initial use. The quality of recovered materials has improved to the point where many recycled polymers now meet specifications for applications that previously required virgin materials, including medical devices and food packaging.

Energy efficiency improvements have transformed the resource intensity of plastic manufacturing processes. Advanced heat recovery systems capture thermal energy from cooling operations and redirect it to other process stages, reducing overall energy consumption by up to 60% in some facilities. Electric injection molding machines have largely replaced hydraulic systems, eliminating oil-related contamination risks while reducing energy usage and enabling more precise process control. For processes requiring high temperatures, microwave and infrared heating technologies provide more efficient energy transfer than conventional methods, heating only the material rather than the surrounding equipment and environment. These efficiency improvements deliver both environmental benefits and significant cost savings, creating a compelling business case for sustainability investments.

Carbon footprint reduction has become a strategic priority across the plastic manufacturing sector, with companies implementing comprehensive programs to measure, report, and systematically reduce greenhouse gas emissions. Renewable energy adoption has accelerated dramatically, with many manufacturers installing on-site solar generation, securing renewable energy purchase agreements, or investing in community renewable projects. Process innovations have targeted emissions-intensive operations, such as replacing chemical blowing agents in foam production with CO₂-based alternatives that have zero global warming potential. Supply chain optimization has reduced transportation-related emissions through strategies like localized production and logistics efficiency improvements. The most progressive manufacturers have achieved carbon neutrality for their operations and are working toward more ambitious goals of climate positivity—removing more carbon from the atmosphere than their entire value chain emits.

Regulatory compliance has evolved from a minimum requirement to a strategic advantage for forward-thinking manufacturers. Rather than merely reacting to current regulations, leading companies actively monitor emerging policy trends and anticipate future requirements, positioning themselves ahead of regulatory curves. Comprehensive chemical management systems track substances of concern throughout product development and manufacturing, enabling rapid adaptation when new restrictions emerge. Standardized environmental impact assessment methodologies allow manufacturers to quantify and communicate the sustainability benefits of their products and processes in ways that satisfy diverse global regulatory frameworks. This proactive approach to compliance reduces business risk while creating market differentiation through demonstrated environmental leadership.

A compelling case study from the consumer electronics sector illustrates these sustainability principles in action. A major manufacturer of electronic device enclosures recently transformed its production facility into what it terms a "circular factory." The operation begins with an advanced sorting system that processes both post-industrial and post-consumer plastic waste, identifying and separating materials by polymer type, additive content, and color. Recovered materials undergo either mechanical or chemical recycling depending on their condition and target application, with sophisticated blending systems creating optimized formulations that match or exceed virgin material performance. The production process itself employs all-electric injection molding machines powered primarily by on-site renewable energy, with comprehensive heat recovery systems that reduce overall energy consumption by 58% compared to conventional operations. Finished components are designed for eventual disassembly and incorporate digital watermarking that facilitates future automated sorting and recycling. The environmental benefits are substantial—95% reduction in virgin material usage, 87% lower carbon footprint, and zero waste to landfill—while the economic performance has actually improved through reduced material costs and energy savings.

As sustainability initiatives continue to advance, the most successful manufacturers recognize that environmental responsibility and business performance are increasingly aligned rather than opposed. By embracing innovative technologies, circular business models, and systems thinking, these companies are simultaneously reducing environmental impacts and creating competitive advantages through improved efficiency, reduced regulatory risk, and stronger customer relationships. This integrated approach to sustainability represents the future of plastic manufacturing—environmentally responsible, economically viable, and increasingly essential in a resource-constrained world.

Digital Transformation in Plastic Manufacturing

The digital transformation of plastic manufacturing has accelerated dramatically in 2025, creating intelligent, connected production ecosystems that bear little resemblance to the factories of the previous decade. This evolution represents far more than the simple automation of existing processes—it constitutes a fundamental reimagining of how plastic components are designed, produced, and delivered. Industry 4.0 principles have moved from conceptual frameworks to practical implementations, with data-driven decision making, interconnected systems, and predictive capabilities becoming standard practice among leading manufacturers.

Industry 4.0 implementation has matured beyond pilot projects and isolated smart machines to encompass comprehensive manufacturing ecosystems. Modern plastic production facilities feature seamless integration between design systems, production equipment, quality control, inventory management, and logistics operations. This integration enables unprecedented levels of flexibility and efficiency, with production parameters automatically optimized based on specific order requirements, material characteristics, and equipment availability. The most advanced implementations incorporate adaptive scheduling algorithms that continuously rebalance production priorities based on real-time conditions, maximizing throughput while maintaining quality standards. These intelligent manufacturing systems can transition between different products with minimal setup time, enabling economical production of smaller batch sizes and greater customization without sacrificing efficiency.

IoT and connected manufacturing have transformed how production equipment is monitored and managed. Today's plastic processing machines incorporate dozens or even hundreds of sensors that continuously measure parameters ranging from basic metrics like temperature and pressure to sophisticated measurements of material viscosity, mold cavity gas evacuation rates, and even molecular orientation in extruded profiles. These sensors communicate through standardized protocols to central monitoring systems that provide comprehensive visibility into operations across entire manufacturing networks. The resulting data streams enable real-time process optimization, predictive maintenance, and quality assurance while creating valuable historical datasets for continuous improvement initiatives. The connectivity extends beyond individual machines to encompass entire production lines and facilities, creating unified digital ecosystems that can be monitored and managed from anywhere in the world.

Digital twins have evolved from simplified virtual representations to sophisticated models that accurately mirror physical manufacturing systems in real-time. These digital replicas incorporate detailed physics-based models of both equipment and processes, updated continuously with data from the physical production environment. Engineers can use these digital twins to simulate process modifications, troubleshoot quality issues, or optimize production parameters without disrupting actual operations. For new product introductions, comprehensive virtual commissioning enables production processes to be fully developed and validated in the digital environment before physical implementation, dramatically reducing startup time and eliminating many traditional sources of quality issues. Some manufacturers report reducing new product introduction cycles by over 60% through these virtual commissioning approaches, while simultaneously improving first-pass quality rates.

Data analytics capabilities have transformed how manufacturers understand and optimize their operations. Advanced analytics platforms can process the massive datasets generated by connected manufacturing systems, identifying patterns and relationships that would be impossible for human operators to recognize. These insights drive continuous improvement initiatives across all aspects of production, from cycle time reduction and quality enhancement to energy efficiency and material utilization. Prescriptive analytics go beyond simply identifying opportunities for improvement to actually recommending specific actions and predicting their likely outcomes. The most sophisticated systems can autonomously implement optimizations within defined parameters, creating self-improving production processes that continuously enhance their own performance without human intervention.

Predictive maintenance systems have revolutionized equipment reliability and uptime in plastic manufacturing operations. By analyzing patterns in sensor data, these systems can detect subtle changes in machine performance that indicate developing problems long before traditional monitoring methods would identify an issue. Maintenance can then be scheduled proactively before failures occur, minimizing unplanned downtime and extending equipment life. The predictive capabilities have become increasingly sophisticated, with some systems now able to identify not just that a problem is developing but specifically which component is deteriorating and how long it will likely continue functioning before failure. This precision enables maintenance resources to be allocated more efficiently, with repairs performed at optimal times that minimize production disruption while preventing costly failures.

The workforce implications of this digital transformation have been significant but not as disruptive as once feared. Rather than eliminating jobs, digitalization has primarily changed the nature of work in plastic manufacturing, with routine tasks increasingly automated while more complex roles requiring human judgment and creativity have expanded. Operators have evolved into process managers who oversee multiple production systems, intervening only when automated controls cannot resolve issues independently. Maintenance technicians now combine mechanical expertise with data analysis skills, using sophisticated diagnostic tools to pinpoint problems with unprecedented precision. Perhaps most significantly, new roles have emerged at the intersection of manufacturing and information technology—positions like manufacturing data scientists, automation integration specialists, and digital twin engineers that didn't exist a decade ago.

A case study from the medical device industry illustrates the transformative impact of digital manufacturing. A leading producer of diagnostic equipment components recently implemented a comprehensive digital transformation of their injection molding operations. The system integrates CAD/CAM design tools with simulation software, production equipment, automated quality inspection, and inventory management into a unified digital ecosystem. When a new component is designed, the system automatically generates optimal process parameters, creates virtual commissioning models, and simulates production scenarios to identify potential issues before physical production begins. During manufacturing, an extensive sensor network monitors every aspect of the process, with AI algorithms continuously optimizing parameters to maintain quality while maximizing efficiency. The results have been remarkable: 42% reduction in new product introduction time, 67% decrease in quality deviations, 28% improvement in overall equipment effectiveness, and 35% lower energy consumption per part produced. Perhaps most significantly, the digital platform has enabled the company to offer customers unprecedented visibility into production status and quality metrics, creating a competitive advantage in a highly regulated industry.

As digital transformation continues to advance, the distinction between physical and digital manufacturing operations will increasingly blur. The future belongs to manufacturers who can effectively leverage data as a strategic asset, creating intelligent, adaptive production systems that continuously evolve to meet changing market demands and operational challenges. This digital revolution represents not just a technological shift but a fundamental reimagining of how plastic components are manufactured in the modern era.

Future Outlook and Emerging Technologies

As we look toward the horizon of plastic manufacturing beyond 2025, several emerging technologies and trends promise to further revolutionize how plastic parts are designed, produced, and integrated into the circular economy. These developments represent not merely incremental improvements to existing methods but potentially transformative approaches that could redefine fundamental aspects of the industry in the coming years.

Biodegradable and compostable plastics have evolved significantly from their early iterations, which often presented challenging tradeoffs between environmental benefits and functional performance. The latest generation of these materials combines sophisticated polymer science with insights from natural systems to create plastics that maintain excellent mechanical and thermal properties during their intended use life but can decompose completely in specific end-of-life environments. Advanced PHA (polyhydroxyalkanoate) formulations derived from bacterial fermentation processes offer a compelling combination of versatility and true biodegradability in both industrial composting facilities and marine environments. Meanwhile, cellulose-based polymers reinforced with nanocrystalline structures have achieved mechanical properties rivaling conventional engineering plastics while maintaining their plant-based origins and compostability. These materials are increasingly moving beyond simple packaging applications into more demanding technical roles, including automotive components, consumer electronics, and even medical implants with controlled degradation profiles.

Nano-enhanced polymers represent another frontier with extraordinary potential to transform material performance. By incorporating precisely engineered nanostructures—including carbon nanotubes, graphene, cellulose nanocrystals, and metallic nanoparticles—researchers have created composite materials with properties that were previously impossible to achieve in plastic components. These include electrical conductivity approaching that of metals, thermal conductivity comparable to ceramics, and mechanical strength exceeding many metal alloys, all while maintaining the light weight and processing advantages of conventional polymers. The challenge has been scaling production of these materials from laboratory curiosities to commercial volumes, but recent breakthroughs in manufacturing processes suggest that nano-enhanced polymers are poised for widespread adoption across industries ranging from aerospace to consumer electronics. Perhaps most significantly, these materials can often achieve their enhanced properties with minimal nanomaterial loading, addressing previous concerns about cost and potential environmental impacts.

Self-healing materials have progressed from academic research to commercial reality, with several systems now available that can automatically repair damage ranging from microscopic cracks to substantial punctures. These materials incorporate various healing mechanisms, including microencapsulated healing agents that release when damaged, reversible chemical bonds that can reform after being broken, and microvascular networks that deliver repair compounds to damaged areas similar to biological systems. The most advanced self-healing polymers can undergo multiple healing cycles without external intervention, significantly extending component lifespan in applications subject to mechanical wear, environmental stress, or impact damage. While currently more expensive than conventional materials, their ability to prevent catastrophic failures and extend service life creates compelling value propositions in critical applications where reliability is paramount or maintenance access is limited.

Circular economy approaches have evolved beyond simple recycling to encompass comprehensive systems for material flow management throughout product lifecycles. Advanced digital tracking technologies—including chemical markers, digital watermarks, and blockchain-based material passports—enable precise identification and sorting of different polymers even after years of service, facilitating high-value recycling rather than downcycling. Modular product design approaches allow components to be easily separated for repair, upgrade, or end-of-life processing without compromising performance or aesthetics during use. Perhaps most significantly, new business models are emerging that shift from selling products to providing services, with manufacturers retaining ownership and responsibility for materials throughout their lifecycle. These product-as-a-service models create powerful incentives for durability, repairability, and eventual recovery of materials, aligning economic and environmental interests in ways that traditional sales models cannot.

The convergence of synthetic biology and polymer science represents perhaps the most revolutionary frontier in plastic manufacturing. Engineered microorganisms can now produce polymer precursors from renewable feedstocks with unprecedented precision and efficiency, creating building blocks that are molecularly identical to petroleum-derived equivalents but with significantly lower environmental impacts. More radically, some researchers are developing biological systems that can produce fully formed polymer structures directly, mimicking natural processes like those that create spider silk or bacterial cellulose but engineered to create specific technical materials. While still in relatively early stages, these biomanufacturing approaches offer the tantalizing possibility of plastic production that operates at ambient temperatures and pressures, uses renewable inputs, creates zero waste, and produces materials designed for eventual biodegradation—potentially addressing virtually all environmental concerns associated with conventional plastic manufacturing.

Looking ahead to the next five years, we anticipate several key developments that will shape the future of plastic parts manufacturing. First, the integration of artificial intelligence into all aspects of the manufacturing process will accelerate, with increasingly autonomous systems that can optimize designs, materials, and production parameters with minimal human intervention. Second, sustainability considerations will become even more central to material and process selection, driven by both regulatory requirements and market demands for environmentally responsible products. Third, the boundaries between different manufacturing methods will continue to blur, with hybrid approaches that combine the advantages of multiple processes becoming increasingly common. Fourth, customization and on-demand production will expand dramatically, enabled by digital manufacturing technologies that eliminate many traditional economies of scale. Finally, we expect continued consolidation of the manufacturing landscape, with successful companies being those that effectively integrate advanced technologies, sustainable practices, and digital capabilities into cohesive manufacturing ecosystems.

These emerging technologies and trends suggest a future for plastic manufacturing that is simultaneously more capable and more sustainable—producing components with unprecedented performance characteristics while dramatically reducing environmental impacts. The industry's continued evolution will require ongoing innovation, investment in new technologies, and perhaps most importantly, a willingness to fundamentally rethink traditional approaches to design, production, and material lifecycle management. For manufacturers willing to embrace these changes, the opportunities are extraordinary—not merely to improve existing products and processes but to create entirely new possibilities that were previously unimaginable.

Conclusion

The landscape of plastic parts manufacturing in 2025 represents a remarkable convergence of technological innovation, environmental responsibility, and business transformation. As we've explored throughout this article, virtually every aspect of the industry has evolved significantly in recent years, creating unprecedented capabilities while addressing historical challenges related to efficiency, sustainability, and product performance.

The manufacturing processes themselves have been revolutionized through digitalization, automation, and materials science advancements. Injection molding has evolved from a relatively simple process into a sophisticated, intelligent manufacturing method with capabilities for multi-material production, micro-scale features, and comprehensive in-process quality assurance. CNC machining has transcended its metal-working origins to become a highly optimized approach for producing precision plastic components with exceptional surface finishes and tight tolerances. Thermoforming has been transformed through advanced control systems and innovative tooling approaches, expanding its applications far beyond traditional packaging. Perhaps most significantly, additive manufacturing has matured from a prototyping technology into a legitimate production method for end-use components, offering design freedom and customization capabilities that were previously impossible.

Material innovations have been equally transformative, with advanced engineering polymers, sustainable alternatives, and specialized composites creating new possibilities for product performance and environmental responsibility. The development of bio-based polymers with mechanical properties rivaling petroleum-derived materials represents a particularly significant breakthrough, enabling manufacturers to reduce environmental impacts without compromising functionality. Meanwhile, smart materials with embedded sensing capabilities, self-healing properties, and programmable responses to environmental stimuli are opening entirely new product categories that blur the boundaries between mechanical components and intelligent systems.

The integration of digital technologies throughout the manufacturing ecosystem has fundamentally changed how plastic parts are designed, produced, and managed throughout their lifecycle. Digital twins, advanced simulation tools, and AI-powered optimization systems have dramatically reduced development cycles while improving first-time quality. Connected manufacturing systems with comprehensive sensor networks provide unprecedented visibility into production processes, enabling real-time optimization and predictive maintenance. These digital capabilities have not only improved operational efficiency but have also created new business models and customer relationships based on data-driven insights and transparency.