Top 15 Metal Casting Parts Manufacturers in 2025: Capabilities, Expertise, and Selection Criteria

Choosing the right casting parts manufacturer in 2025 is more complex than ever.

Metal casting buyers must evaluate suppliers on quality, capacity, certifications, and process expertise. With global supply chains shifting, finding reliable casting partners is critical.

Many engineers struggle to balance cost, lead time, and technical capability. This guide highlights 15 top-tier metal casting manufacturers worldwide and explains how to evaluate them for your project.

Table of Contents

- What Are the Criteria for Casting Selection?

- What Are the Five Metal Casting Processes?

- What Is the Future of Casting?

- Who Is the Largest Casting Producer in the World?

- Top 15 Metal Casting Parts Manufacturers in 2025

- FAQs

- Conclusion

What Are the Criteria for Casting Selection?

Not every casting fits every application. Making the wrong choice leads to failures, delays, or safety issues.

The best casting solutions depend on application, required strength, precision, finish, and production volume. Buyers must match process with performance and cost.

Key Casting Selection Criteria

| Criterion | Description |

|---|---|

| Mechanical Properties | Required strength, ductility, and hardness |

| Precision | Dimensional tolerance and surface finish needs |

| Material Type | Iron, aluminum, brass, stainless steel, etc. |

| Volume | One-off, small batch, or mass production |

| Cost and Lead Time | Balance between budget and timeline |

| Post-Processing | Machining, coating, or heat treatment requirements |

| Certification | ISO, IATF, and industry-specific standards |

At Prime, we advise clients on casting feasibility and process optimization, ensuring both cost-effectiveness and performance for diverse industrial needs.

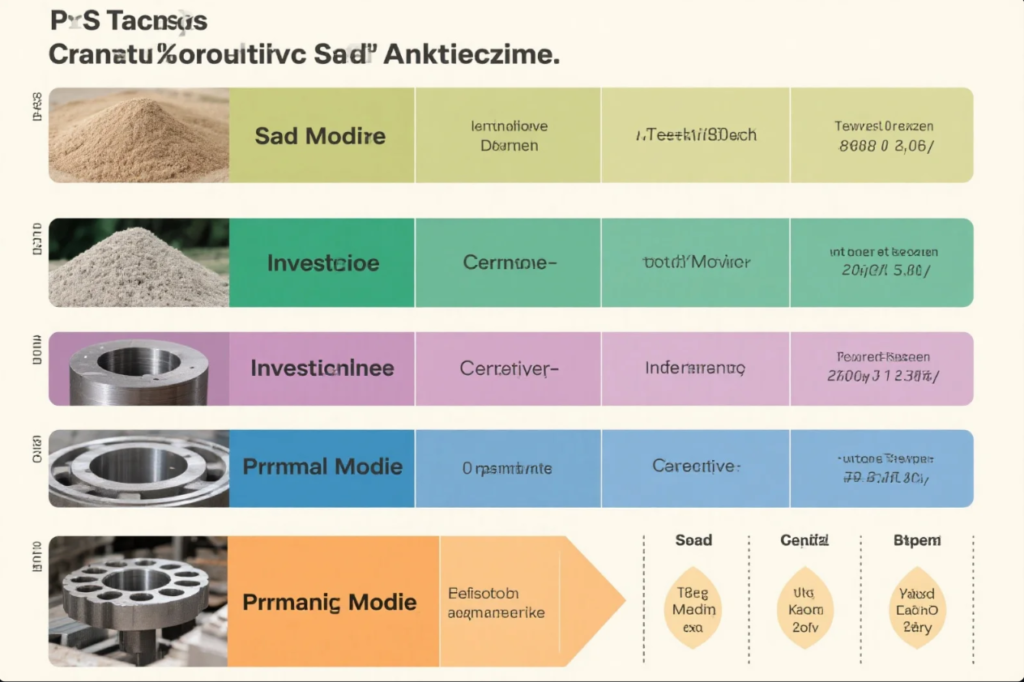

What Are the Five Metal Casting Processes?

Casting isn’t one-size-fits-all. Each method suits different part designs and industry needs.

The five main casting processes are sand casting, investment casting, die casting, centrifugal casting, and permanent mold casting. Each has unique benefits and trade-offs.

Five Core Casting Methods

| Method | Strengths | Best Use Case |

|---|---|---|

| Sand Casting | Low-cost, large parts, simple tooling | Automotive frames, pulleys |

| Die Casting | High-volume, tight tolerance, smooth finish | Electronics housing, engine parts |

| Investment Casting | Complex shapes, fine details | Aerospace, medical, jewelry |

| Centrifugal Casting | High-density, minimal porosity | Pipes, rings, cylinders |

| Permanent Mold Casting | Better than sand, reusable mold | Industrial fittings, impellers |

We offer customized casting parts in all major processes. Prime is known globally for ISO-certified casting production and short delivery cycles across North America and Europe.

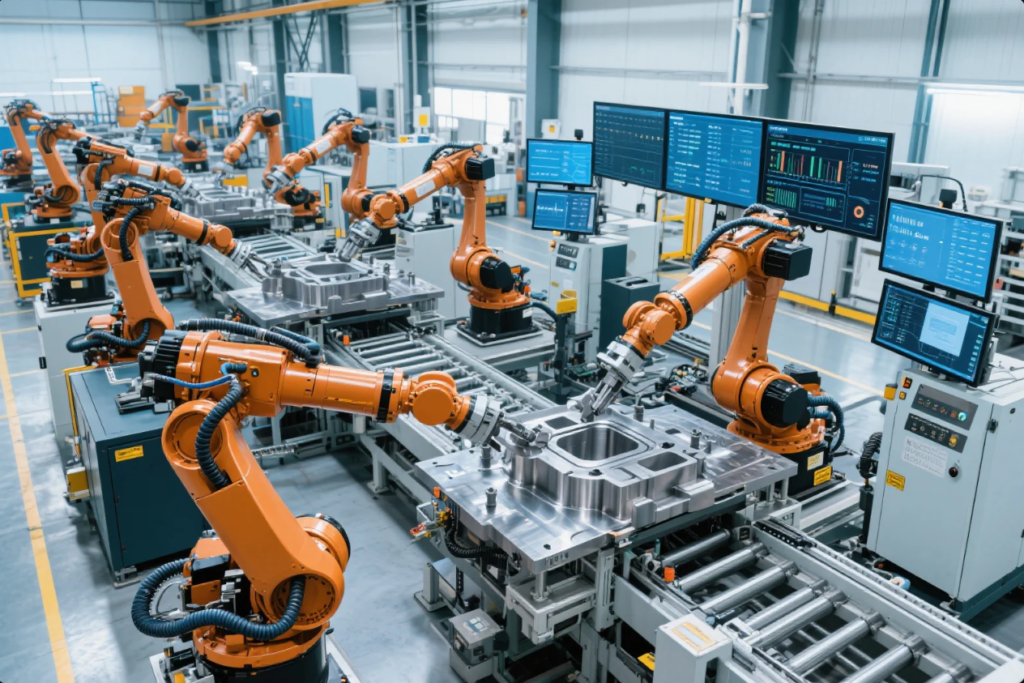

What Is the Future of Casting?

The casting industry is evolving. Manufacturers must adopt new technologies or risk falling behind.

The future of casting includes automation, simulation-driven design, eco-friendly materials, and additive manufacturing. Sustainability and digitalization lead the transformation.

2025 Casting Industry Trends

- Green Casting Materials: Focus on recyclable and low-carbon metals

- AI Process Control: Real-time monitoring for quality consistency

- Simulation-Based Tooling Design: Reduces defects, optimizes yield

- 3D-Printed Molds & Cores: Shorter development cycles

- Supply Chain Localization: Risk mitigation and faster delivery

Prime stays ahead with digitally simulated casting workflows and integrated machining. Our foundries use AI-controlled pour stations and 3D mold printing, ensuring maximum repeatability.

Learn more about casting industry innovations from Foundry Magazine.

Who Is the Largest Casting Producer in the World?

Global rankings change fast. But China remains the dominant player in output volume.

As of 2025, China's Weichai Group and Wencan Holding lead the global casting market. In the U.S., companies like Nemak and MetalTek continue to thrive in advanced sectors.

Top 5 Global Casting Giants (by Output)

| Company Name | Country | Specialization | Annual Output (2024 est.) |

|---|---|---|---|

| Weichai Foundry | China | Engine blocks, industrial parts | 1.5M+ tons |

| Nemak | Mexico | Automotive castings | 1.2M tons |

| Wencan Holding | China | EV parts, high-pressure die cast | 900K tons |

| MetalTek | USA | Aerospace, nuclear components | 600K tons |

| Ryobi Die Casting | Japan | Precision auto parts | 550K tons |

Top 15 Metal Casting Parts Manufacturers in 2025

1. Prime Custom Parts (China)

Specialties: ISO-certified casting parts, CNC integration, global delivery

2. Nemak (Mexico)

Specialties: Automotive casting, aluminum structural parts

3. MetalTek International (USA)

Specialties: High-performance alloys, aerospace castings

4. Ryobi Die Casting (Japan)

Specialties: Pressure die casting, automotive housing

5. Weichai Group (China)

Specialties: Heavy-duty engine components

6. Wencan Holdings (China)

Specialties: EV platform parts, complex aluminum castings

7. Ahresty Corporation (Japan)

Specialties: High-precision aluminum castings

8. GF Casting Solutions (Switzerland)

Specialties: Lightweighting solutions, digital casting

9. Endurance Technologies (India)

Specialties: Motorcycle and auto castings

10. Zhenjiang Xinya Foundry (China)

Specialties: Gray iron and ductile iron parts

11. Dynacast (USA)

Specialties: Zinc and magnesium precision die casting

12. Shiloh Industries (USA)

Specialties: Lightweight castings for energy-efficient vehicles

13. Bühler Group (Switzerland)

Specialties: Foundry systems and die casting automation

14. Form Technologies (USA)

Specialties: Precision casting, medical and telecom components

15. Aludyne (USA)

Specialties: Suspension systems and chassis casting

FAQs

Q1: What is the most cost-effective casting method?

A1: Sand casting is generally the most affordable, especially for large or low-volume parts.

Q2: What certifications should a casting supplier have?

A2: Look for ISO 9001, IATF 16949, and AS9100 depending on the industry.

Q3: Can casting defects be avoided completely?

A3: Not always, but simulation tools and digital monitoring can minimize them significantly.

Q4: How do I choose between casting and CNC machining?

A4: Casting is better for complex shapes at volume. CNC is ideal for high-precision and customization.

Q5: Does Prime offer mixed processes (casting + CNC)?

A5: Yes, Prime specializes in combining casting with CNC finishing, saving clients time and cost.

Conclusion

Metal casting remains essential in 2025. The right partner delivers quality, speed, and peace of mind.

Looking for a reliable casting parts supplier? Contact Prime today for free consultation and competitive quotes. We specialize in custom casting parts, CNC integration, and ISO-certified production for global B2B buyers.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com