A Complete Guide to Custom Metal Parts: Materials, Tolerances, and Surface Finishes

Ordering custom metal parts in 2025 isn’t just about sending a drawing to a supplier. The metal type, required tolerances, and surface treatments all impact cost, performance, and turnaround.

In this comprehensive guide, we walk you through how to select the right materials, define accurate tolerances, and choose appropriate finishes for your next project.

Engineers, buyers, and procurement managers often struggle with vague specs, poor surface treatments, and unclear tolerance requirements. We’ve created this guide to eliminate guesswork and improve your sourcing outcomes.

What Are the Best Materials for Custom Metal Parts?

Choosing the wrong metal leads to product failure, deformation, or skyrocketing costs. That’s why material selection is the first—and most important—step in custom part production.

The right metal depends on mechanical strength, corrosion resistance, weight, and how the part will be used.

Common Metals in 2025 Manufacturing

| Material | Key Benefits | Common Uses |

|---|---|---|

| Aluminum 6061-T6 | Lightweight, corrosion-resistant, weldable | Enclosures, brackets, heat sinks |

| Aluminum 7075 | High strength, less corrosion resistance | Aerospace, motorsport parts |

| Stainless Steel 304 | Rust-proof, durable, easy to fabricate | Food-grade components, marine fixtures |

| Stainless Steel 316 | Extreme corrosion resistance | Medical, chemical, marine, outdoor uses |

| Carbon Steel 1018 | Economical, strong, good machinability | Machinery, shafts, general structural components |

| Brass C360 | Aesthetic, conductive, corrosion-resistant | Valves, fittings, electronics |

| Titanium Grade 2/5 | Lightweight, strong, corrosion-resistant | Aerospace, medical implants, performance parts |

🔗 Compare technical specs easily using Matmatch or MakeItFrom.com.

Dive Deeper: Cost vs. Performance

At Prime, we help customers optimize both function and price. For example, a client building outdoor sensor housings switched from 304 stainless to anodized aluminum 6061—cutting weight and cost without sacrificing performance.

Material decisions also influence machining time and tool wear. Brass is faster to machine than stainless steel, reducing labor cost.

Why Are Tolerances Important in Metal Machining?

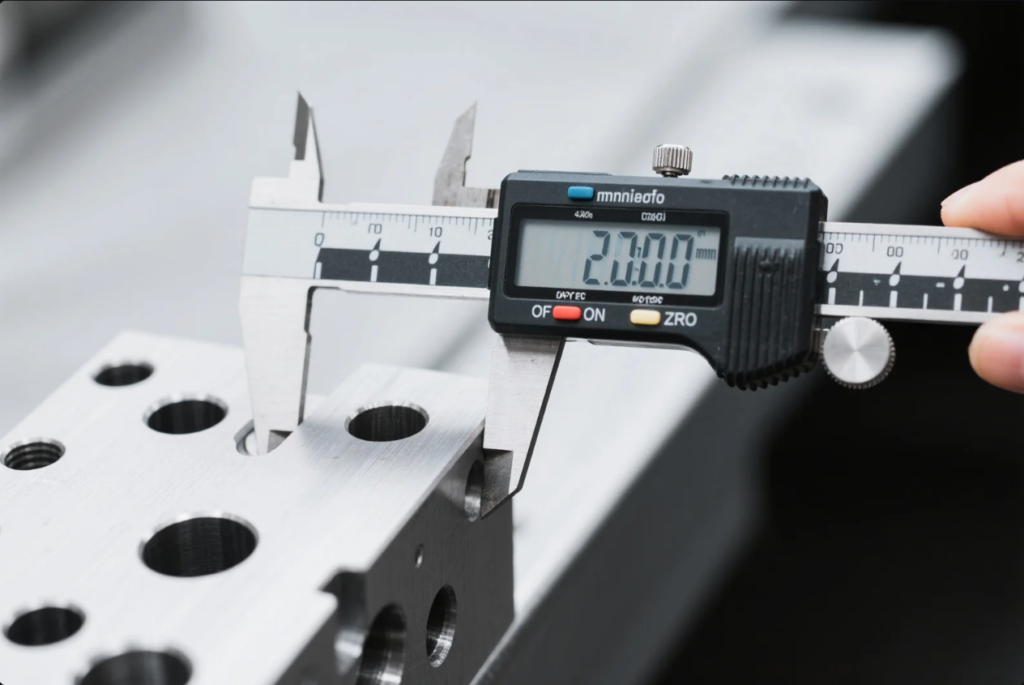

Tolerances determine how precisely a part is made. Loose tolerances save money. Tight tolerances ensure function but drive up cost.

Poor tolerance selection causes fit issues, premature wear, or assembly problems. Getting it right avoids costly rework.

Tolerance Types & When to Use Them

| Tolerance Category | Typical Range | Examples |

|---|---|---|

| General Tolerance | ±0.1 mm | Brackets, housings, covers |

| Medium Precision | ±0.05 mm | Light mechanical interfaces |

| High Precision | ±0.01 mm or tighter | Bearings, shafts, mating components |

📖 Learn more from the ASME Y14.5 GD\&T standard for industry-standard fits and tolerancing.

Dive Deeper: How to Reduce Tolerance Waste

Tight tolerances require slower machining speeds, better tooling, and extra inspections. That means higher unit cost and longer lead times.

At Prime, we help clients balance functional needs with budget by:

- Applying tight tolerances only where needed

- Using precision gauges for inspection

- Consulting during DFM (Design for Manufacturing) stage

Use H7/h6 for shaft-hub fits, but stick to ±0.1 mm for panel cutouts or cosmetic features.

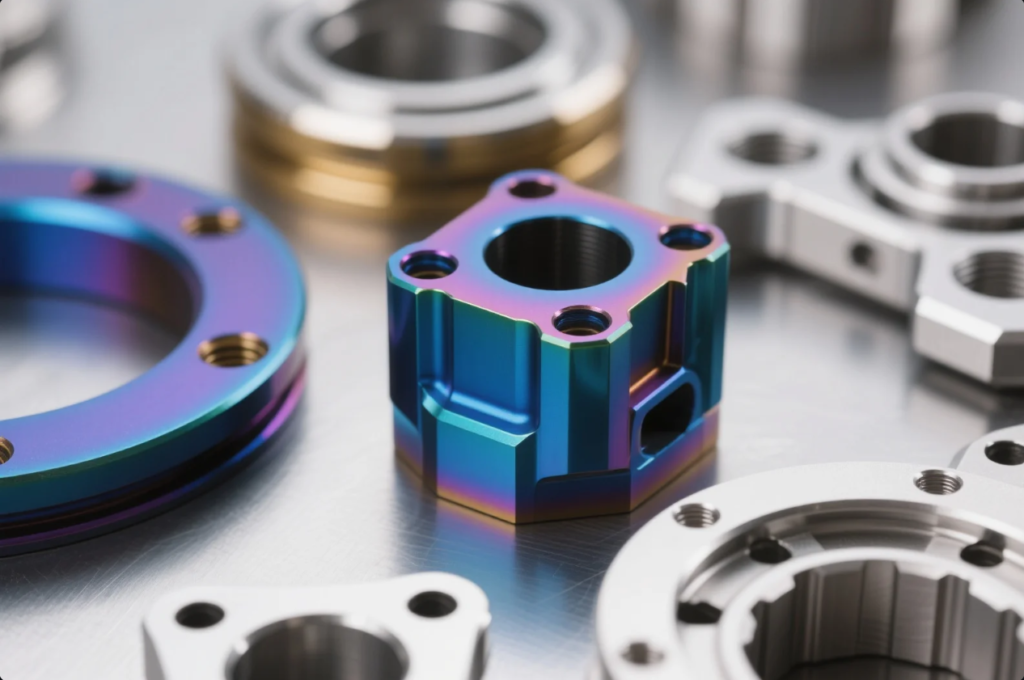

How Do Surface Finishes Affect Functionality and Appearance?

Surface treatment isn’t just about how parts look—it affects corrosion resistance, assembly, and mechanical behavior.

Choose your finish based on environmental exposure, mechanical stress, friction, or branding requirements.

Popular Metal Finishes in 2025

| Finish Type | Key Features | Best For |

|---|---|---|

| Anodizing | Color + corrosion resistance | Aluminum parts, outdoor hardware |

| Powder Coating | Tough, thick layer, decorative | Frames, panels, brackets |

| Electropolishing | Smooth, removes microburrs | Stainless steel, medical parts |

| Zinc Plating | Thin rust barrier, cost-effective | Carbon steel, electrical parts |

| Black Oxide | Low-cost black finish, aesthetic | Tooling, decorative steel parts |

| Passivation | Removes free iron, improves corrosion | Stainless steel fittings |

🔗 Learn more from Finishing.com or browse real examples at Protolabs.

Dive Deeper: Matching Finish to Function

Finishes add thickness (e.g. powder coating adds \~0.1 mm), which impacts precision fits. We recommend adjusting part drawings accordingly.

At Prime, we run finish simulations and provide test pieces. A client in Canada once requested anodized red sensor covers—and we sent five finishes in advance to match their brand tone exactly.

Material Certifications and Compliance

In global trade, certifications protect both buyer and seller. Whether for FDA-regulated medical devices or RoHS-compliant electronics, documentation matters.

Always verify certifications for material composition, process quality, and environmental compliance.

Common Standards in Metal Parts Production

| Certification | Purpose | Who Needs It |

|---|---|---|

| ISO 9001 | General quality management system | All industries |

| IATF 16949 | Automotive sector quality system | Car part manufacturers |

| AS9100 | Aerospace grade QMS | Aviation and defense |

| RoHS / REACH | Restricts hazardous substances | Electronics, EU trade |

| Material COC / MTC | Confirms alloy composition | Regulated or safety-critical |

🔗 Check compliance standards at RoHS Guide or REACH Europe.

At Prime, every order includes a Certificate of Conformity. For clients in Europe and the U.S., we provide EN/ASTM material equivalency.

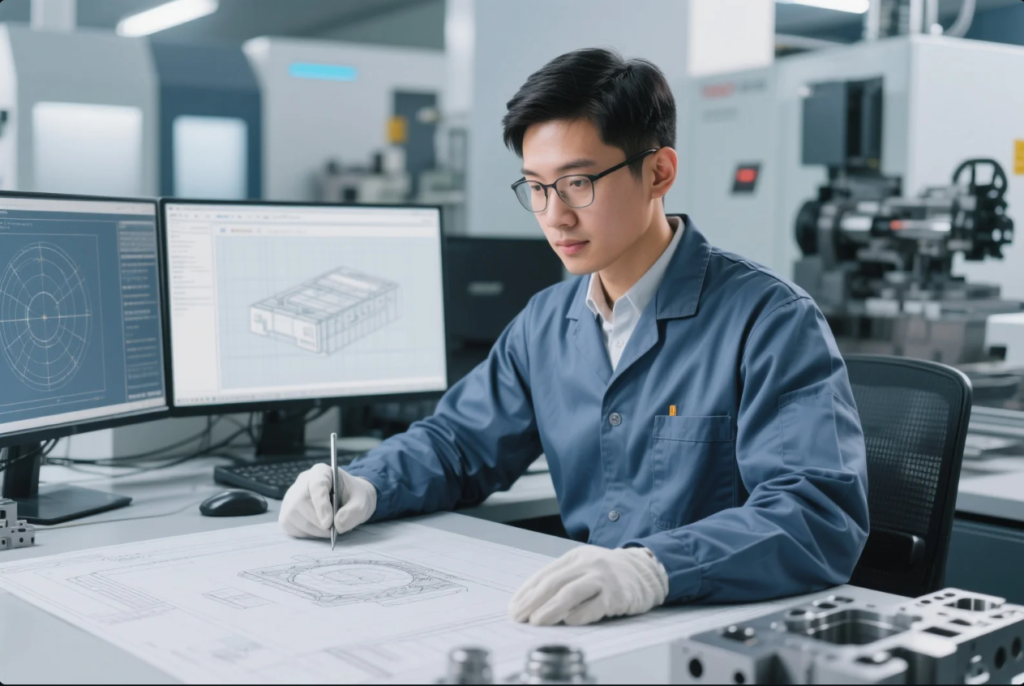

Custom Part Design Considerations

A good design reduces cost, improves reliability, and speeds up production.

Avoid undercuts, deep pockets, and impossible corners. Think like a machinist or toolmaker.

Best Practices for Custom Metal Designs

- Use standard hole sizes (M3, M6, etc.)

- Avoid very thin walls (<1 mm for metals)

- Fillet corners to reduce stress

- Add chamfers for smooth assembly

- Label finish, tolerance, and material clearly

📘 Tools like Fusion 360, SolidWorks, and Onshape help optimize parts before manufacturing.

At Prime, our engineers offer DFM reviews to catch issues before production. Clients who use this service cut rejection rates by 70%.

FAQs

Q1: Can I mix finishes on one part?

Yes, but we need to mask or sequence processes. Ask us about dual-finish techniques.

Q2: What is a fair tolerance for a CNC bracket?

±0.05 mm is ideal for holes and edges. ±0.1 mm is fine for cosmetic or low-precision features.

Q3: Can I request a finish sample before mass production?

Absolutely. We provide samples for approval before your first full order.

Q4: Do you provide surface roughness reports?

Yes. Ra value reports are available for polished, ground, or electropolished parts.

Q5: Is aluminum strong enough for structural parts?

Aluminum 7075 and 6061-T6 are very strong. But for load-bearing parts, we may recommend carbon or alloy steel.

Conclusion

When sourcing custom metal parts in 2025, get the basics right: material, tolerance, and finish. Each decision shapes your product’s cost, performance, and lead time.

📩 Need expert help on your next RFQ?

Email us at [email protected]

🌐 Visit our site: https://primecustomparts.com/

We offer ISO-certified machining, stamping, welding, and finishing—delivered globally from our 10 production lines in China.