A Complete Guide to Injection Molded Plastic Parts for OEM Projects

Avoid poor-quality parts and unreliable suppliers. Injection molding creates uniform, precise, and scalable plastic parts. This comprehensive guide explains every step—process, materials, tolerances, CAD submission, quoting, and delivery. Perfect for OEM project managers, engineers, and procurement specialists.

What is Injection Molding and Why OEMs Use It

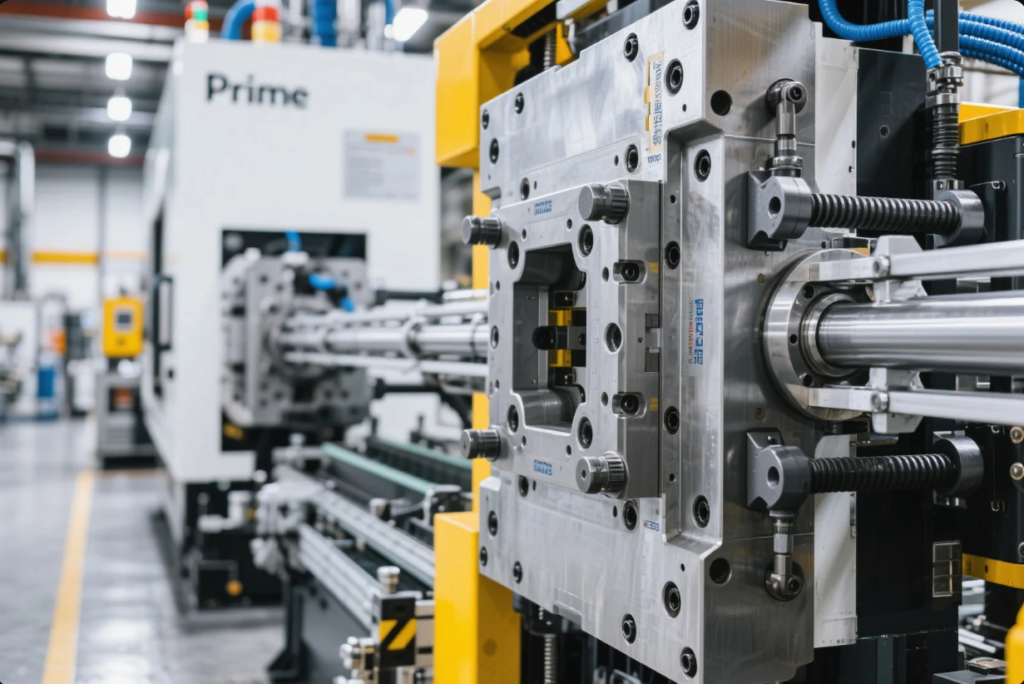

Injection molding produces consistent, identical plastic parts in high volume. OEMs use it for its efficiency, precision, and cost-effectiveness. The machine melts plastic and injects it into a mold cavity. After cooling, it ejects a perfect part. High repeatability and low cycle times (under 60 seconds) make it ideal for large-scale production runs. Industries like automotive, medical, aerospace, and consumer electronics rely on this process for quality and speed.

Why OEMs Prefer Injection Molding

-

Volume & Cost Efficiency

The more parts you produce, the lower the cost per unit. Molds amortize quickly over high volumes. -

Precise Tolerances

Standard tolerance is ±0.05 mm, but advanced tooling can achieve ±0.01 mm—essential for snap fits and precise assemblies. -

Surface Finish Options

Molds can produce anything from high-gloss SPI-A1 finishes to matte D3 textures. Texturing and polishing options are wide-ranging. -

Complex Shapes Possible

Enables undercuts, threads, inserts, living hinges, and intricate designs—difficult or impossible with other processes. -

Material Variety

Choose from engineering thermoplastics like PC, PEEK, or specialty resins such as food-grade PP.

Step-by-Step: How the Process Works

Injection molding involves a defined, repeatable sequence:

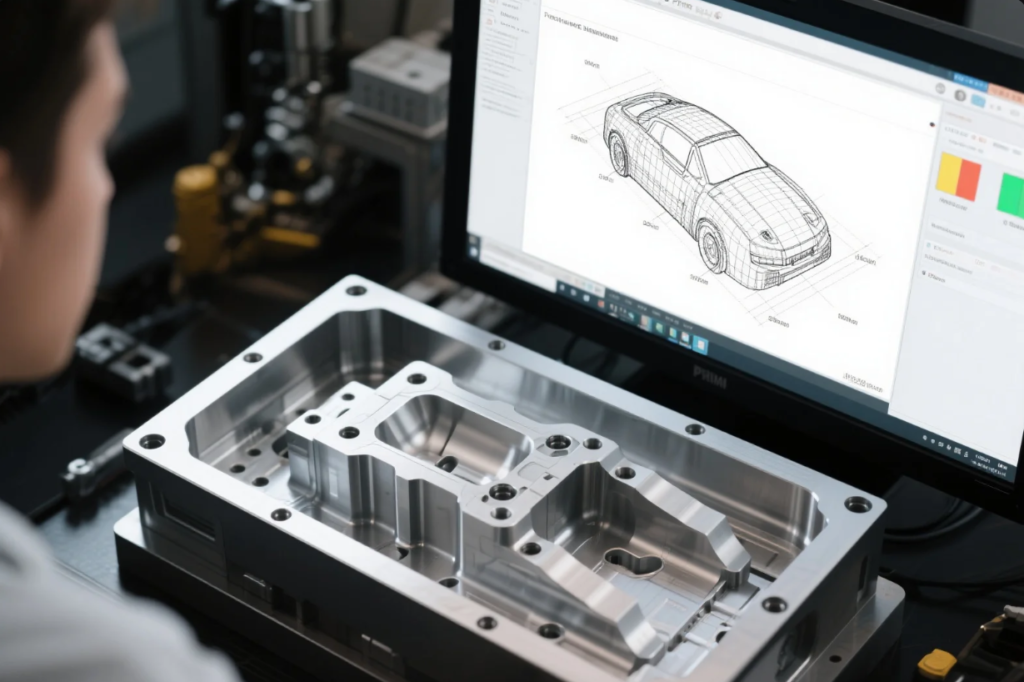

Design & DFM Review

When we receive your CAD, we start with a Design-for-Manufacturability review. We check for issues like thick walls, missing draft, or unsupported features. We recommend changes and optimize the part design free of charge.

Mold Fabrication

Mold steel or aluminum undergoes machining to create precise cavities. Steel mold tooling is durable and capable of high volume; aluminum molds offer cost-effective prototyping options.

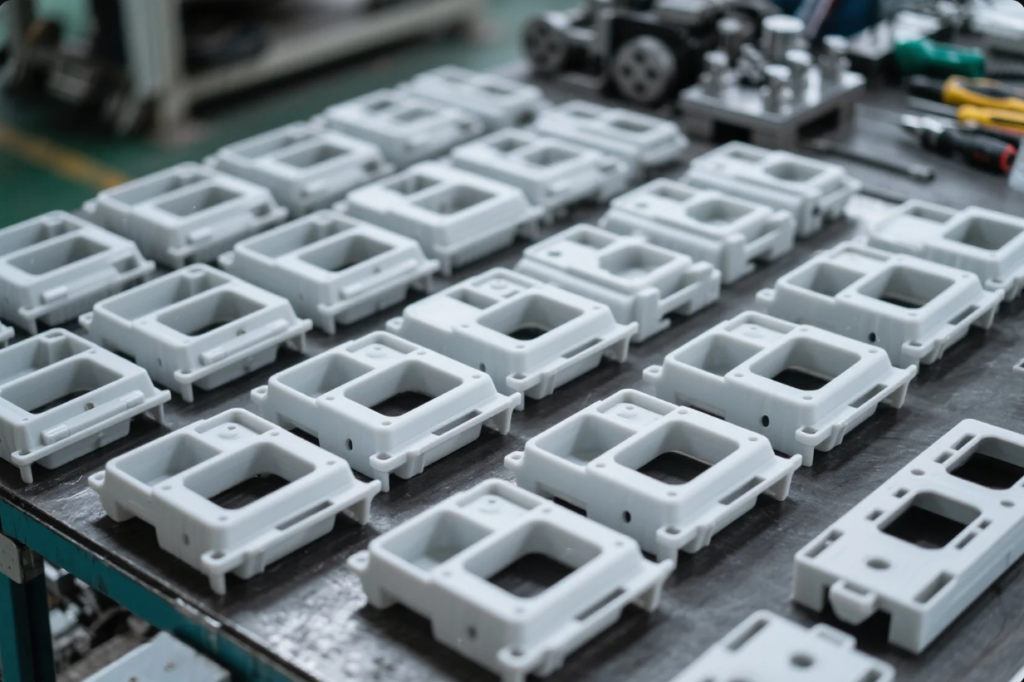

T1 Sampling

Initial molded parts (T1 samples) are tested for dimension, fit, aesthetics, and performance. Adjustments are made based on your feedback—until the part is perfect.

Full Production

Once approved, molds run on high-speed machines in automated cycles. Thermoplastic granules melt, inject, cool, and eject cleanly, under precise control.

Quality Control & Packaging

We use CMM (Coordinate Measuring Machine) reports to verify critical dimensions. Visual checks on aesthetics, plus moisture-proof, EPE-foam shipping packaging with export labels included.

| Process Step | Typical Duration |

|---|---|

| DFM & Quotation | 1–2 days |

| Mold Building | 10–15 days |

| T1 Sample Creation | 2–5 days |

| Full Production | 3–7 days |

| QC & Packing | 1–2 days |

🔗 Mold design overview – Wikipedia

Best Plastic Materials for Injection Molding

| Material | Properties | Common Uses |

|---|---|---|

| ABS | Impact-resistant, low cost | Electronics housings, toys |

| PC | Strong, transparent, heat-resistant | Lenses, medical device covers |

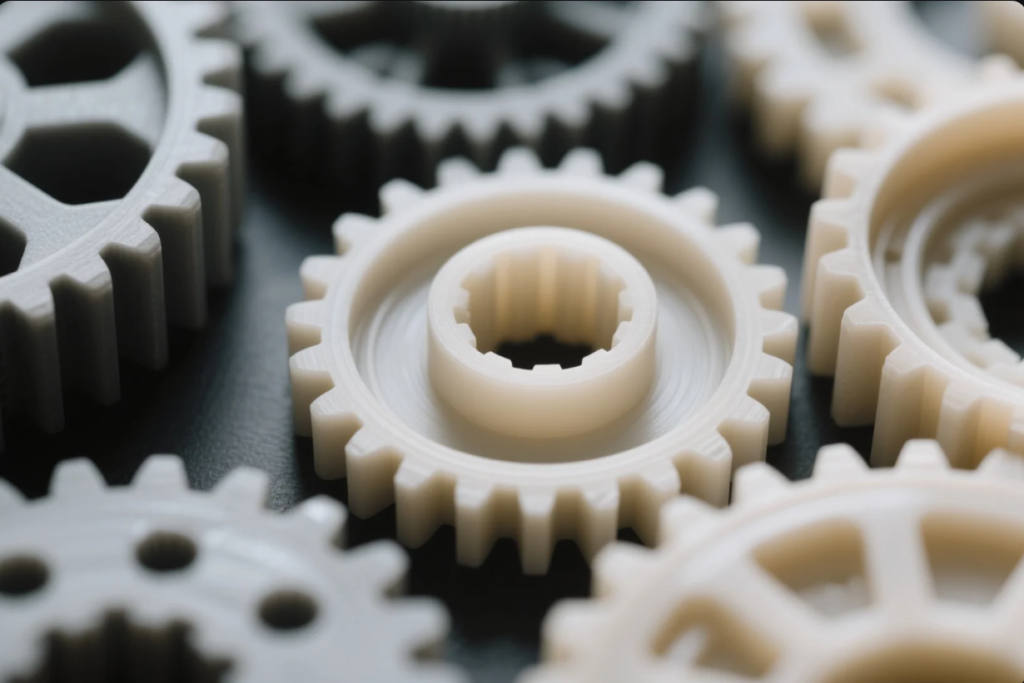

| PA66 | Wear-resistant, strong | Gears, snap fits, automotive parts |

| POM | Low friction, stiff | Bearings, mechanical joints |

| PP | Chemical-resistant, FDA approved | Food containers, medical parts |

| PEEK | High-temp, flame-resistant, medical grade | Aerospace, surgical tools |

Choosing the Right Resin

- ABS for cost-sensitive, durable housings.

- PC for clear/strong design pieces.

- PA66 for structural and wear applications.

- POM where precision and low friction are critical.

- PP for safe food contact and chemical exposure.

- PEEK for high-temp, high-performance needs.

Prime stocks 20+ certified resins, including UL-rated, FDA-approved, and flame-resistant grades. We guide you to the ideal choice based on application and environment.

Tolerances, Surface Finishes, and Part Complexity

Tolerance Ranges

| Feature | Standard Mold | Precision Mold |

|---|---|---|

| General dimensions | ±0.05 mm | ±0.02 mm |

| High-precision areas | — | ±0.01 mm |

Maintenance of tight tolerances relies on mold quality, steel hardness, consistent mold temperature, and material behavior.

Surface Finishes (SPI/VDI)

- SPI-A1: High polish, mirror finish, optical surfaces.

- SPI-B2: Semi-gloss, popular for consumer electronics.

- SPI-D3: Textured matte for anti-slip or aesthetic use.

- VDI 24–36: Light grain texture for automotive panels.

🔗 SPI surface finishes – Wikipedia

Handling Complexity

Prime supports features like:

- Undercuts with side-pull inserts or sliders.

- Snap-fits with engineering tolerances.

- Inserts and overmolding for embedded metal components.

- Multi-cavity molds for scalable production.

- Living hinges in PP designs for flexible parts.

We run mold flow analysis on each design to prevent warping, sink marks, weld lines, or air traps.

How to Submit CAD Files for Fast Quotes

Send us the following:

- 3D CAD files: STEP or IGES preferred for design accuracy.

- Quantities: Prototype to million-piece volumes.

- Material requirements: Include specific grades or certifications.

- Surface finish or logo needs: Texture, gloss/matt, laser engraving.

- Packaging or certification needs: FDA-safe, anti-static, moisture-barrier, EPE-lined boxes.

📧 Email: [email protected]

🌐 Website: PrimeCustomParts.com

🔗 CAD for injection molding tips – SolidSmack

Your quote arrives in under 24 hours. We also offer fast CNC prototypes (5–7 days) and T1 samples (2–3 weeks).

FAQs on Injection Molded Parts

Can injection molding achieve ±0.01 mm tolerance?

Yes—on critical features, with hardened steel and precision mold control.

What’s the lead time for prototypes?

CNC prototypes arrive in 5–7 days. T1 sample sets arrive in 2–3 weeks, based on mold complexity.

Do you accept STL files?

Yes—but STEP or IGES are strongly preferred for mold accuracy.

What material choices do you recommend?

We offer ABS, PC, POM, PA66, PP, PEEK, and specialty grades based on your requirements.

Can you run low-volume production?

Yes. We offer trial, pilot and small-batch runs using bridge tooling.

Contact Prime for OEM Plastic Molding

📧 [email protected]

🌐 https://primecustomparts.com

With Prime, you receive:

- Free DFM consultation

- ISO-certified build and production

- ±0.01 mm repeatability

- SPI surface finishing and overmolding

- Fast quoting, prototyping, and quality production

- Global shipping and export-ready packaging

Conclusion

Injection molding offers scalable, reliable, and precise plastic part production. It’s ideal for OEMs needing high volume, tight tolerances, and design flexibility.

Take the next step—send your CAD file to Prime and get a free quote within 24 hours.