Analysis of machining trends for custom metal parts in 2025: a comprehensive guide from stamping to CNC?

Supply chains shift fast. Deadlines loom. I must choose smarter processes to stay ahead.

This 2025 guide compares stamping, CNC, casting, and welding with clear use cases, simple DFM rules, and risk controls. I link directly to trusted standards like ASME Y14.5, ISO 9001, and practical tool notes from Autodesk Fusion and Renishaw.

I speak as a B2B factory partner. I run ten lines. I export worldwide. So I keep the advice plain and actionable.

How does precision stamping improve part consistency and productivity?

Buyers still fight variation, burrs, and slow cycle time. I faced that too. So I moved to servo presses, progressive dies, and smarter in-die checks. Then my output climbed while scrap fell.

Precision stamping boosts repeatability through fixed tooling, coil feed control, and SPC. It compresses cycle time and stabilizes Cpk when I combine die sensors, gauging, and clear GD\&T.

Dive-Deeper: a 2025 stamping playbook that scales without drama

I treat stamping as a closed loop. First, I standardize incoming material with mill certs and hardness checks. Then I tune die clearance, add strip-end and misfeed sensors, and log critical features with SPC. Also, I align inspection to datums from ASME Y14.5. Therefore, my team catches drift early and acts before bad parts pile up.

Press and die choices that pay back fast

I favor servo presses for tricky forms because variable stroke profiles reduce snap-through. So I get cleaner edges and longer tool life. I also integrate in-die tapping from partners like Pronic. Thus I remove a secondary step and guard lead time. For machine insight, I study servo motion resources from AIDA and SEYI. Then I match tonnage curves to my die set.

Simple poka-yoke and burr control that actually work

I add poka-yoke features per the plain ideas on Wikipedia. So strips only load one way, and bolts only fit the right hole. I also manage burr height by pairing sharper dies with correct clearance and monitored lube. For fundamentals, I still point newer staff to the burr page. It helps them visualize what we fight each shift.

Data discipline that keeps parts consistent

I log key dimensions on control charts. So I see trends before they bite. I target Cpk ≥ 1.33 for mass builds, and I check more often on startup. Also, I keep go/no-go gauges for fast checks, which the go/no-go article explains well. Then I escalate to CMM on first article and before shipment.

| RFQ Checkpoint | What I confirm quickly | Helpful reference |

|---|---|---|

| Material & temper | Yield, elongation, thickness tolerance | Steel sheet basics |

| Die design | Progressive vs transfer path | Stamping overview |

| In-die operations | Tapping or insertion options | Pronic in-die |

| Press motion | Servo profile suitability | AIDA DSF |

| Control plan | SPC, Cpk, gauge plan | SPC basics |

I weave SEO long-tails cleanly here: custom stamping parts supplier, ISO-certified stamping manufacturer, progressive die stamping China, and burr-controlled stamping parts. So buyers find a specific fix, not vague claims.

How does CNC machining enable small-batch customization of complex parts?

Teams worry about setup time, fixture cost, and missed windows. I used to worry too. But I changed my approach. I built zero-point fixtures, templated tool libraries, and robust probing. Then small batches became fast and predictable.

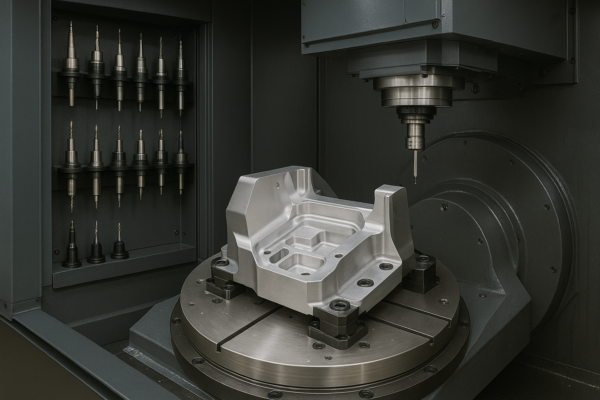

CNC machining shines for complex, short-run parts. Five-axis kinematics, adaptive toolpaths, and on-machine probing cut lead time and hold tight tolerances, while keeping costs visible.

Dive-Deeper: a flexible CNC system that handles ECOs without chaos

I design the cell first, not the part. I standardize holders, stick-out, and tool numbers. I map my library in Autodesk Fusion and tag proven feeds and speeds. Also, I program roughing with Adaptive Clearing to keep chip load steady. Therefore, cutters live longer and finish improves. I verify every setup with Renishaw spindle probes and routine macros, so offsets update fast.

Workholding that reduces changeover pain

I mount SCHUNK VERO-S pallets and add soft jaws with dowel pins. So my swap time drops to minutes. Then I queue parts by similar tool lists. Therefore, spindle uptime stays high while ECOs flow through calmly.

DFM rules that protect quality and your wallet

I push simple CNC DFM every time. I increase internal radii to at least 1.5× cutter radius. I thicken walls when resonance shows up. I cap thread depth near two diameters. For approachable guides, I share articles from Protolabs and Xometry. So teams lock stable geometry before quoting.

Transparent quotes for small batches

I split non-recurring work from recurring piece price. So you see fixture cost, program hours, and cycle time separately. Then you can amortize across pilot and ramp. Also, I show price breaks clearly. Therefore, planners decide with data, not hope.

| CNC Control Point | My default method | Why it helps | Helpful link |

|---|---|---|---|

| Offset setup | Spindle probing | Faster, fewer mistakes | Renishaw OMP60 |

| Roughing | Adaptive toolpaths | Constant load, longer life | Fusion Adaptive |

| Library | Standard tools | Predictable finish | Fusion tool library |

| Workholding | Zero-point pallets | 5-minute changeovers | VERO-S |

| DFM | Radii, walls, threads | Lower chatter, better yield | Xometry CNC guide |

I include useful long-tails: precision CNC machining for small batches, CNC parts tight tolerance supplier, rapid 5-axis prototype machining, and CNC aluminum 6061 anodized parts. So engineers who search find relevant terms fast.

Combination of casting and welding: a solution for high-strength structural components?

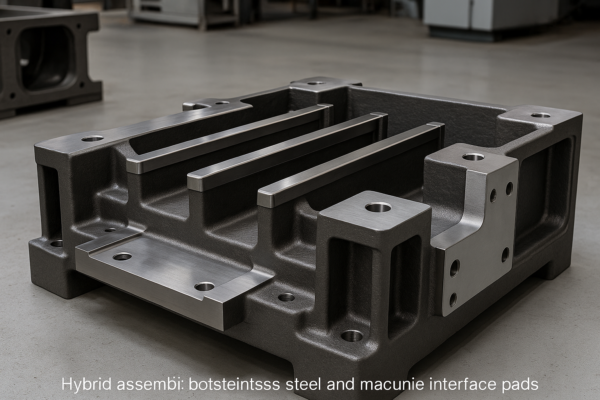

Some frames want complex geometry and mass from castings. Others need local reinforcement and flexible interfaces from welds. I do both when loads spike or bolt patterns vary. So I protect strength and cost at the same time.

Cast-and-weld hybrids deliver near-net shapes plus tailored strength. Good WPS/PQR, proper preheat, and NDT keep joints sound while machining time and piece cost stay in control.

Dive-Deeper: design, qualify, and inspect hybrid builds that last

I start with the load path and service environment. I run fill and solidification simulation to place risers and avoid hot spots. For concept checks, I point teams to accessible pages on ductile iron and aluminium–silicon alloys. Then I plan weld landings and smooth transitions to avoid stress risers. I qualify procedures against ISO 15614-1, and I confirm soundness with UT or radiography per primers on ultrasonic testing and industrial radiography. Therefore, the structure survives field abuse and audits.

Casting choices that reduce rework later

I pick ductile iron 65-45-12 for tough housings, or A356 for lighter frames. So machining stays reasonable while stiffness holds. I add generous draft and rounded ribs, then I place feeders where the model needs them. I also simulate gating with tools like MAGMASOFT and ProCAST; even quick vendor studies help. If the system will face salt or heat, I add finishes like anodizing, electrophoretic deposition, or electroless nickel. Thus corrosion stays in check.

Welding controls that survive audits

I compute carbon equivalent using the simple formulas on Wikipedia. Then I select preheat and interpass control. I choose fillet or full-penetration joints based on load. I document WPS and PQR carefully. Also, I plan stress relief for heavy sections if distortion risks rise. Finally, I check with UT or RT before paint. Therefore, failures in the field become rare, and warranty claims stay low.

| Hybrid Step | Practical action | Purpose | Helpful link |

|---|---|---|---|

| Casting model | Run fill/solidification checks | Avoid porosity and hot spots | Al–Si alloys |

| Weld plan | Write WPS/PQR to code | Repeatable, auditable joints | ISO 15614-1 |

| Preheat rule | Compute carbon equivalent | Reduce crack risk | CE overview |

| NDT | UT or RT before paint | Verify integrity | UT basics |

| Finish | Coat for environment | Control corrosion | E-coat concept |

I anchor keywords here: ISO-certified casting parts manufacturer, welding assemblies supplier, hybrid casting-welded components, and ductile iron castings with stainless overlays. So buyers who need structural reliability can find me quickly.

Guide to material selection: How to balance performance, cost, and delivery time?

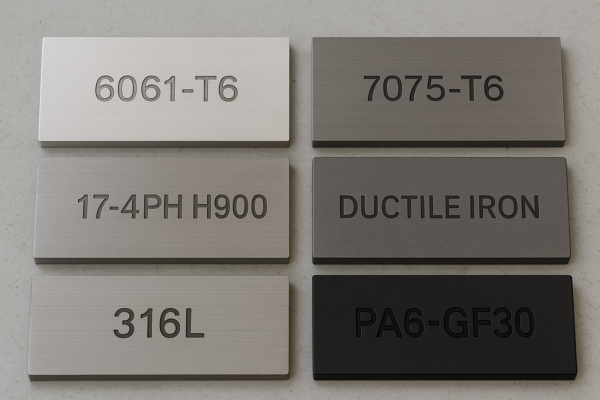

Many teams over-spec alloys and then wait for mill slots. I did that before. Now I score options on function, machinability, and lead time. Then I pick the lowest-risk grade that still meets the job.

I balance strength, weight, corrosion resistance, and stock availability. I offer two backup grades, plus finish options, so projects do not stall when supply shifts.

Dive-Deeper: a simple, honest method to pick materials that ship on time

I start with function and failure modes. I ask how the part fails first: yield, wear, fatigue, or corrosion. Then I filter candidates that meet the must-have spec. I check regional stock and typical lead time. I use approachable references so everyone on the team can follow. For example, I link 6061 and 7075 pages on Wikipedia and Wikipedia, a 17-4 primer on Wikipedia, and 316L basics on Wikipedia. I also confirm polymer picks like Nylon 6 and glass-filled grades. Therefore, discussions stay clear and fast.

Finish choices that replace prestige alloys

Sometimes I swap a high-nickel grade for a cheaper base metal plus coating. I use anodizing on aluminum, or electroless nickel on steels. I also apply passivation per simple passivation notes for stainless. So I hit function without paying extra for the base alloy. Then I validate with salt fog per ASTM B117 when the spec calls it.

Packaging and logistics that protect parts and schedules

I pack with VCI materials from vendors like Zerust and aim for ISTA 1A drop performance. I follow export guides from FedEx and DHL. I add tilt or shock labels from SpotSee TiltWatch. Therefore, cartons arrive clean even after long ocean routes.

| Use case | Starting grade | Why I pick it | Helpful link |

|---|---|---|---|

| General CNC brackets | 6061-T6 | Easy to machine and anodize | 6061 basics |

| Light but very strong | 7075-T6 | High strength; watch corrosion | 7075 basics |

| Strength + corrosion | 17-4PH | Heat-treatable to many H states | 17-4 primer |

| Corrosive environments | 316L | Chloride and food grade service | 316L primer |

| Structural castings | Ductile iron | Toughness and cost balance | Ductile iron |

| Non-conductive grips | PA6 GF30 | Good strength and feel | Nylon 6 |

I weave long-tails here: ISO-certified casting parts manufacturer, stainless steel CNC parts supplier, custom stamping parts supplier China, plastic insert molding manufacturer, and industrial fasteners wholesale. So searchers find answers that match their intent.

FAQs

Can you ship CNC samples quickly without quality risk?

Yes. I use pallet pools, shared tool libraries, and probing. So I ship in days, not weeks. You can see why probing matters by scanning the Renishaw OMP60 page.

Do you hold tight stamping tolerances at volume?

Yes. I run servo presses and progressive dies with die sensors. I align control plans to SPC and review GD\&T per ASME Y14.5. So parts stay consistent.

Can you prepare PPAP and MSA for automotive audits?

Yes. I prepare Level 3 PPAPs with MSA and capability studies. I also keep calibration records per ISO 9001. So audits move smoothly.

Which payment and trade terms do you support for global buyers?

I support T/T or L/C. I ship under Incoterms® 2020 like FOB, CIF, DAP, or DDP. So costs and risks stay clear.

How do you prevent rust and crush damage during ocean transit?

I use Zerust VCI, desiccants, and ISTA-inspired cartons. I follow FedEx packing and DHL packaging advice. So parts arrive clean and intact.

Do you combine stamping blanks with CNC finishing and welding?

Yes. I form near-net blanks, then I mill interfaces, and finally I weld or rivet. I qualify welds to ISO 15614-1. So assemblies meet structural targets.

Can you help choose between 6061 and 7075 for brackets?

Yes. I compare stiffness, strength, and corrosion risks using simple primers on 6061 and 7075. Then I suggest finishes that match the job.

Do you supply fasteners and plastic parts with the metal builds?

Yes. I kit fasteners and mold inserts like PA6 GF30. For quick polymer context, I share the Nylon 6 page. So engineers see pull-out and temperature basics.

How do you handle labeling and customs codes?

I print clear English labels and HS codes. I confirm code families with the WCO. So customs clearance stays smooth.

What proof do you provide before shipment?

I send CMM reports, process photos, and packing checks. I also share simple SPC snapshots and gauge R\&R notes based on public MSA concepts. So you sign off with confidence.

Conclusion

Choose stamping for scale, CNC for change, hybrids for strength, and smart materials for speed; then ship with robust packing.

I serve B2B buyers only. I supply stamping parts, CNC parts, welding parts, casting parts, fasteners, and plastic parts. I run ten production lines with ISO oversight. I export to North America, Europe, the Middle East, Australia, and more. I answer quickly, quote clearly, and ship on time.

Ready to move now? Visit primecustomparts.com and email [email protected] for a free consultation, a firm quote, and a tailored plan. I commit to fast delivery and stable quality, order after order.