Are plastic parts durable?

Many buyers worry if plastic parts will last under real-world use.

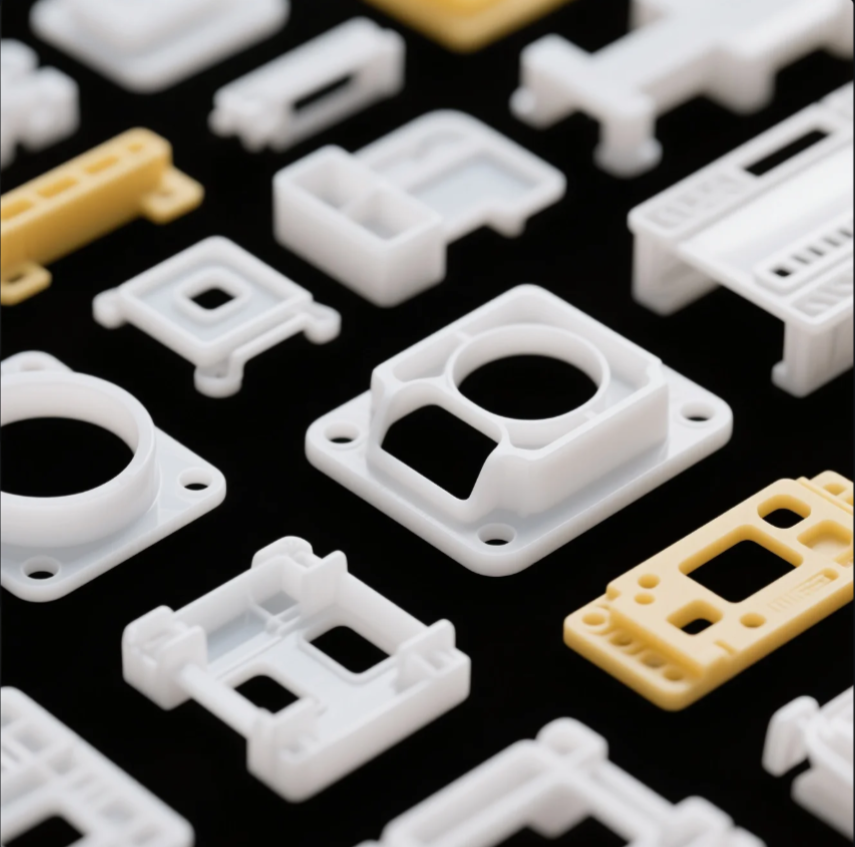

Plastic parts can be highly durable. Their strength depends on the type of plastic, part design, and manufacturing process.

Choosing the right plastic helps avoid cracking, wear, and costly replacements.

Let’s explore how durable plastic really is—and where its limits lie.

How durable is plastic?

Buyers often assume plastic means weak. That’s not always true.

Many plastics like Polycarbonate, Nylon, and ABS offer excellent impact resistance, wear tolerance, and lifespan.

Plastic durability depends on heat, UV exposure, and load stress. When designed right, plastic parts last for years.

Examples of Durable Plastics

| Plastic | Durability Traits | Common Uses |

|---|---|---|

| Polycarbonate | High impact strength | Helmets, shields |

| Nylon | Abrasion-resistant | Gears, hinges |

| ABS | Stable under stress | Casings, panels |

At Prime, we match materials to your application. We use ISO-certified plastic resins and strict molding controls to ensure long-term performance.

Is plastic durable or non-durable?

The answer depends on what kind of plastic you use.

Plastic can be either durable or non-durable. Engineering plastics are long-lasting. Disposable plastics break down quickly.

Not all plastics are created equal. We help you pick based on lifespan and function.

Durability Comparison

| Plastic Type | Lifespan | Usage |

|---|---|---|

| Engineering plastic | 5–20 years | Auto, medical, tools |

| Commodity plastic | 1–3 years | Packaging, wrappers |

| Bioplastics | 6–12 months | Compostable items |

Prime provides engineering-grade plastic parts for global B2B clients who need stable performance across all industries.

What are 3 disadvantages of plastic?

Despite the benefits, plastic also has limits. Clients often ask about the risks before committing.

Three main disadvantages of plastic are environmental impact, heat sensitivity, and brittleness in low-quality grades.

These issues can be managed through material selection and proper design.

Plastic Disadvantages

- Environmental waste – Plastics don’t break down easily.

- Heat limits – Most soften above 100–150°C.

- Cracking – Cheap plastics crack under load or in cold.

At Prime, we only use high-grade raw materials and offer custom blends for better resistance. We also help clients reduce waste with optimized part design and packaging.

What is the toughness of a plastic?

Some clients confuse strength and toughness. They ask which plastic absorbs impact without breaking.

Toughness refers to a plastic’s ability to absorb energy without fracturing. Polycarbonate and Nylon are known for high toughness.

Toughness is key in safety-critical parts and dynamic load environments.

Toughness Rating of Common Plastics

| Plastic | Toughness Level | Example Use |

|---|---|---|

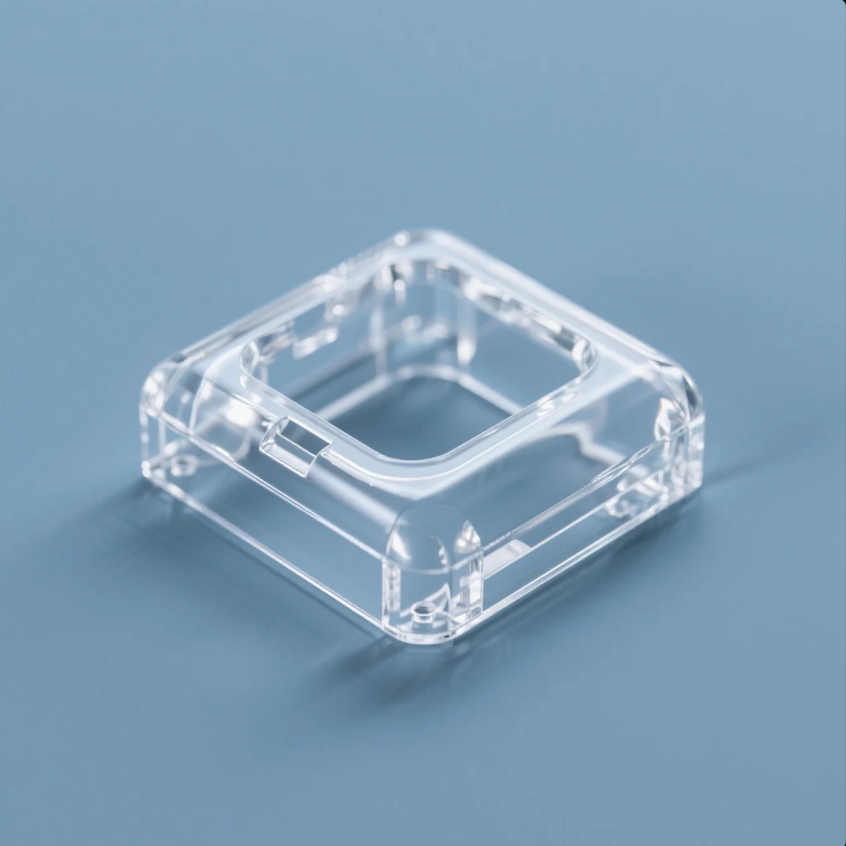

| Polycarbonate | Very High | Impact shields, lenses |

| Nylon | High | Moving parts, joints |

| ABS | Moderate | Enclosures, brackets |

| Acrylic | Low | Displays, covers |

We help clients choose materials based on real-world stress tests, not just catalog specs. That leads to better product life and fewer failures.

Conclusion

Plastic parts can be extremely durable when the right material and design are used. Tough plastics offer long life and strong performance.

Looking for durable custom plastic parts? Contact Prime today for a free consultation and quote. We offer ISO-certified solutions, fast delivery, and expert support to help you build longer-lasting products.