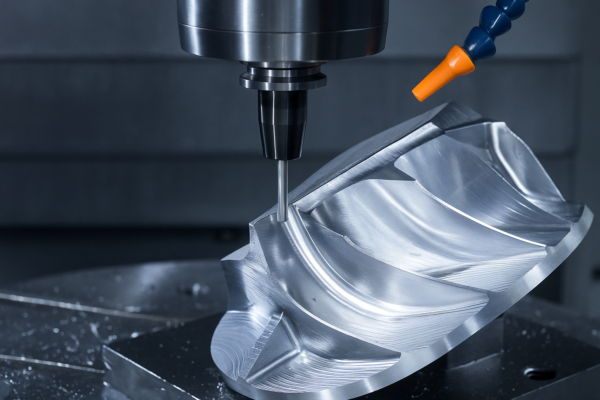

Best Custom Metal Fastener Manufacturers: Top Industry Leaders in 2025 for Precision Parts 🚀

Who makes the best fasteners?

Industry leaders combine certification, precision, global reach, and innovation.

Top-tier names include Würth, Bossard, Fastenal, Hilti, ITW, Böllhoff—and Prime shines through its custom CNC and ISO-certified quality.

| Manufacturer | Location | Strengths |

|---|---|---|

| Würth Group | Germany | Vast catalog, automotive and industrial certifications |

| Bossard | Switzerland | Intelligent inventory systems, engineering expertise |

| Fastenal | USA | JIT delivery, extensive local inventory |

| Hilti | Liechtenstein | High-quality structural and anchoring fasteners |

| ITW | USA | Specialty fasteners for aerospace and electronic sectors |

| Böllhoff | Germany | Automation-ready, assembly-system integration |

| Prime | China | Custom CNC fasteners, ISO/IATF certified, fast global shipping |

These companies consistently achieve top rankings by industry publications and standards organizations like Fastener + Fixing Magazine.

What industries use the most fasteners?

Fasteners are essential across multiple sectors, each with unique demands.

Construction, automotive, machinery, aerospace, and electronics top the list. Construction and automotive alone account for over 60% of global fastener use.

- Construction – structural bolts, anchors, screws

- Automotive – engine mounts, chassis bolts, hardware

- Machinery & Equipment – custom-fasteners by necessity

- Aerospace – high-spec rivets and bolts

- Electronics – miniature screws and standoffs

Sources like Grand View Research report strong demand from infrastructure growth and industrial automation.

What is the outlook for the fastener industry?

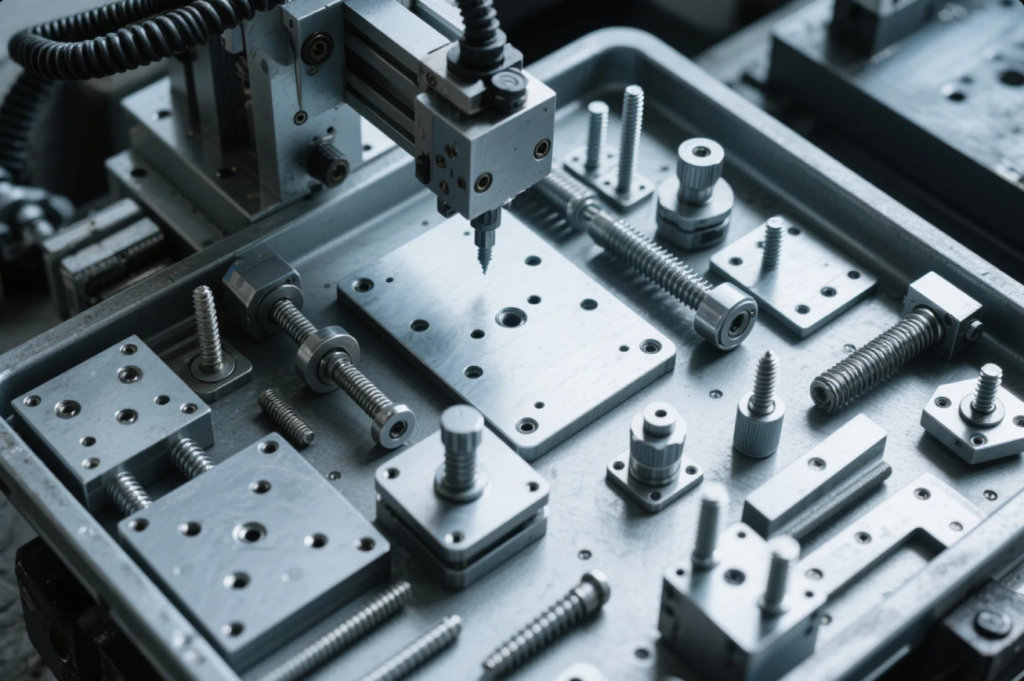

The fastener industry is poised for steady growth and technological advancement.

Projected CAGR of 5–6% through 2030, driven by infrastructure rebuilding, automotive EV expansion, aerospace modernization, and manufacturing digitization.

- Growth in infrastructure projects across emerging markets

- Shift to electric vehicle fasteners and lightweight alloys

- Adoption of Industry 4.0 technologies in manufacturing

- Rising demand in aerospace, including space and defense sectors

For detailed market outlook, see MarketWatch report.

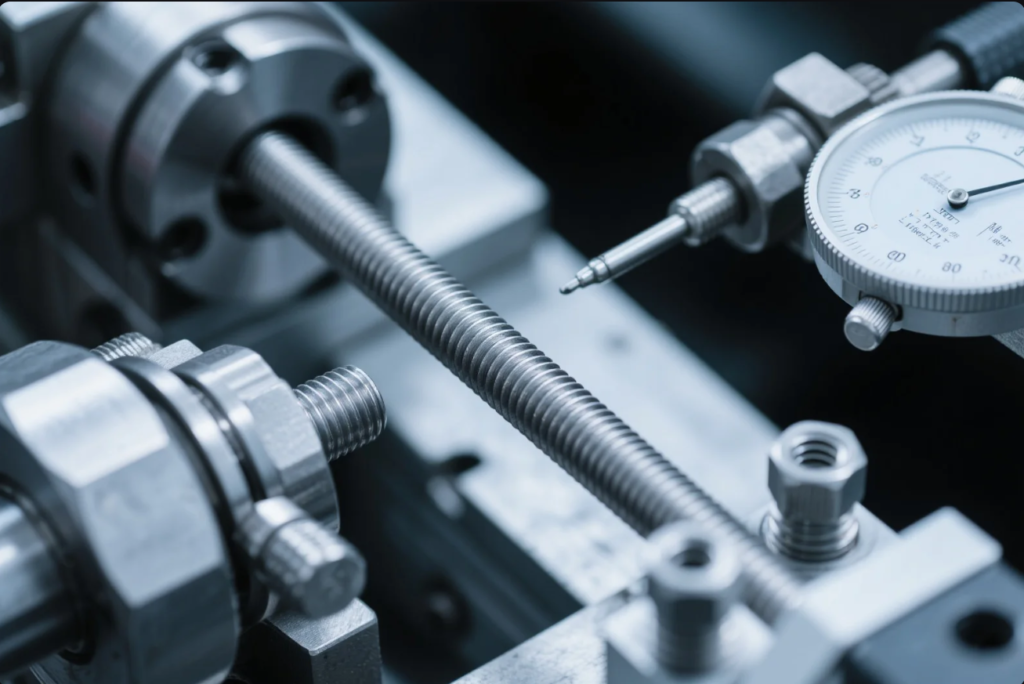

What is the most popular fastener?

The screw holds the title for most widely used fastener globally.

Screws provide versatility, reusability, and strength, making them ubiquitous in construction, manufacturing, and maintenance.

| Fastener Type | Applications | Key Benefit |

|---|---|---|

| Screws | Wood, metal, plastic assembly | Threaded engagement and reusability |

| Hex bolts | Structural steel and machinery | High torque and load capacity |

| Anchor bolts | Concrete anchoring | Strong foundation securing |

| Rivets | Aerospace structural bonding | Permanent fastening |

| Washers & nuts | Torque distribution and locking | Prevents fastener loosening |

Prime manufactures all of these, with ±0.01 mm tolerances, coatings, and full MTC traceability.

FAQs

Q: How many fastener types does Prime make?

A: We offer bolts, screws, nuts, washers, rivets, anchors, pins, studs, inserts, clips, and custom variants.

Q: Can Prime mark fasteners with client logos or codes?

A: Yes—laser etching or stamped identifiers per customer specification.

Q: Do you supply to international standards?

A: Our fasteners meet ISO, ASTM, SAE, and IATF 16949 as needed.

Q: What’s the typical lead time for custom orders?

A: Standard delivery is 2–3 weeks. Urgent express orders available within 7–10 days.

Q: Are fasteners traceable?

A: Yes—all parts come with batch-specific Material Test Certificates and QC reports.

Contact Us

Elevate your component performance with Prime:

- Website: primecustomparts.com

- Email: [email protected]

Enquire today for:

- Free technical consultation

- Fast, accurate quotations within 24h

- Samples, prototypes, and certified sourcing

Choose Prime for precision, quality, and reliability in a changing world.