How Custom Metal Molds Improve Efficiency in Industrial Production Lines?

Unoptimized tools create waste, cycle delays, and line failures. As production demand grows, generic tooling can’t keep up.

Custom metal molds improve productivity by ensuring repeatability, faster cycles, and stable part quality in industrial environments.

In this article, I’ll walk through the key reasons tooling matters, what types of tools exist, and how custom molds boost manufacturing KPIs.

Why is tool design important?

Tool design controls the entire product outcome. A flawed design causes scrap, downtime, and inefficiency across thousands of units.

Great tool design ensures speed, dimensional consistency, and ease of maintenance.

Four Ways Tool Design Impacts Production

| Factor | Result |

|---|---|

| Cooling System | Faster cycles, less warping |

| Gate Location | Balanced flow, fewer voids or weld lines |

| Ejector Layout | Reliable part removal, no distortion |

| Insert Modularity | Lower maintenance downtime |

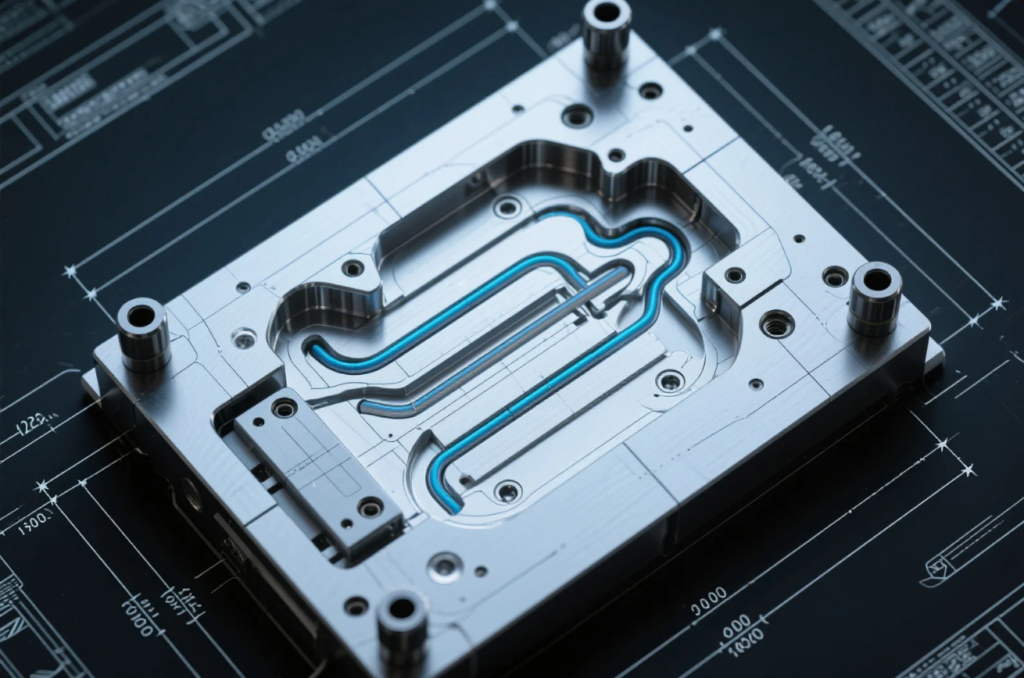

At Prime, we redesigned a mold for an industrial valve client in Italy. The original cycle time was 38 seconds. After updating the cooling channels and vent placement, we cut it to 23.7 seconds, improving output by 37%.

Dive into detailed design principles from Autodesk Mold Design or learn through ToolingU-SME online programs.

What is tooling in manufacturing?

Tooling is the set of engineered hardware—like molds, dies, jigs, and fixtures—that defines how material gets shaped in production.

In molding, tooling refers to the entire structure that enables metal or plastic to be formed into a repeatable part.

Major Types of Tooling in Industrial Molding

| Component | Purpose |

|---|---|

| Mold Base | Holds all parts, allows alignment |

| Cavity/Core Inserts | Forms part shape and tolerances |

| Cooling Channels | Controls mold temperature and cycle time |

| Ejector Pins/Plates | Removes parts safely |

| Guide/Slider Units | Enables complex shapes, undercuts |

Tooling also includes electrodes for EDM, pre-hardened steels, and hot runner systems. Our tooling at Prime uses certified H13, NAK80, and 420SS from global suppliers.

Learn more about tooling standards from Thomasnet – Manufacturing Tooling.

Why are tools important in production?

Every manufacturing line depends on accurate, consistent tools. Even a 0.2 mm misalignment can ruin output when scaled.

Tools ensure each product matches design spec, reduce human error, and cut per-unit cost.

What Happens When Tooling Fails?

- Scrap rate increases

- Rework costs rise

- Production stops for repairs

- Delivery deadlines are missed

We supported a U.S. electronics company that previously faced a 6.3% defect rate on a 4-cavity mold. After switching to our redesigned mold with better venting and cavity steel, their defects dropped below 0.9% in the first two months.

Explore real-world examples at Modern Machine Shop – Tooling Case Studies or SME’s Productivity Toolkit.

What is the importance of using tools and equipment?

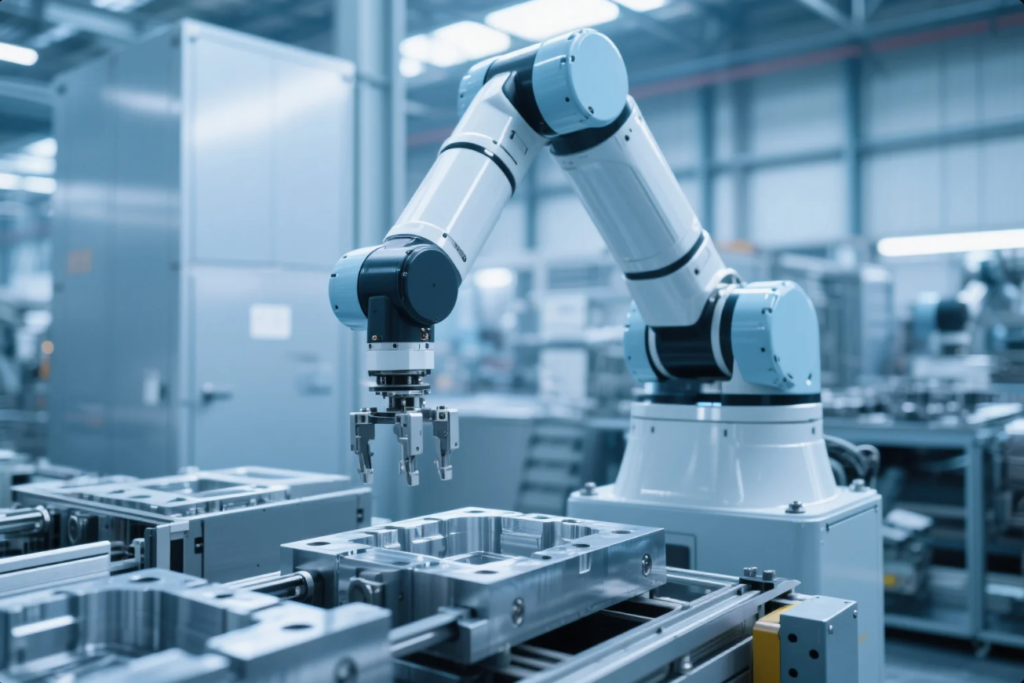

The right equipment enables reliable, high-speed manufacturing. A good mold can run 24/7 for millions of cycles if maintained.

Correct tools reduce machine wear, enhance safety, and improve worker productivity.

Why You Should Use the Right Tools

| Equipment Feature | Benefit |

|---|---|

| Hardened Core Material | Lasts longer under friction |

| Precision Finish | Reduces flash, better part finish |

| Optimized Runner Layout | Even pressure, balanced fill |

| Predictive Maintenance | Extends mold life with fewer breakdowns |

At Prime, our maintenance protocols include surface regrinding, pin replacements, and annual flow analysis. This extends mold usability by 25–35% on average.

Review equipment best practices at The Fabricator – Tool Maintenance and Machine Design – Tooling Tips.

Real-World Benefits of Custom Molds

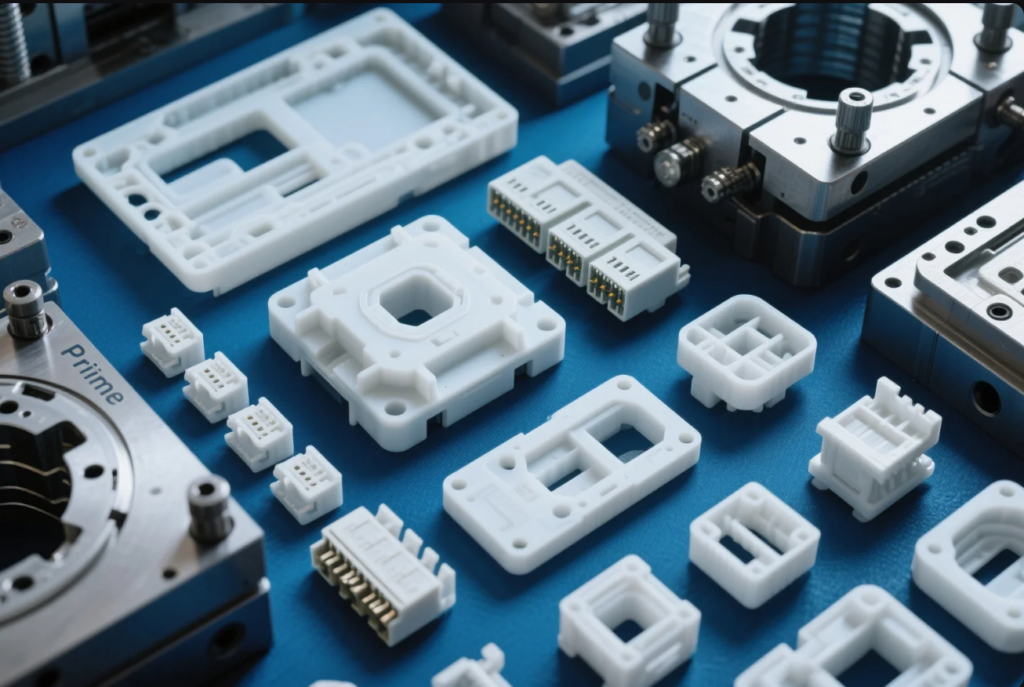

From auto parts to smart devices, custom molds help manufacturers reduce defects, scale faster, and improve consistency.

Custom metal molds are built for your specific part geometry, volume, and application—no compromises.

Top Benefits in Industrial Production

- Reduced Cycle Times – Faster cooling and ejection

- Longer Tool Life – Right steel and polish level

- Consistent Quality – Less variation per batch

- Fewer Repairs – Thanks to modular insert design

- Lower Per-Part Cost – Especially over 50k units

We supported an Indian pump manufacturer by switching them from a generic sand mold to a precision steel die mold. Their productivity increased by 62%, and mold repairs went from monthly to once per year.

Need ROI insights? Try Xometry’s Mold Cost Estimator

FAQs

1. What file types can I send for mold design?

We accept STEP, IGES, DXF, STL, SolidWorks, and can help optimize poor CAD models.

2. How fast can Prime deliver a mold?

Rapid molds: 7–10 days. Full steel tools: 15–30 days including test runs and QA.

3. What certifications do your molds meet?

We build to ISO 9001, RoHS, and CE standards. We also support custom FAI and PPAP requirements.

4. What industries do you serve?

We serve automotive, HVAC, consumer electronics, medical devices, packaging, and telecom.

5. Do you provide post-delivery support?

Yes. We offer lifetime technical support, re-polishing, and global shipping for replacement parts.

Conclusion

If your production line struggles with rejects, long cycle times, or inconsistent part quality, it’s time to upgrade your tooling.

At Prime, we build custom metal molds optimized for your line—from CAD to export-ready crate. We help manufacturers around the world run faster, with less waste and more profit.

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let’s build a better line—one custom mold at a time.