What Are the Best Metal Parts for Construction, Energy, and Transportation Industries?

Custom metal components play a vital role in heavy industries. From skyscrapers to rail systems, the choice of metal impacts safety, durability, and efficiency. Prime specializes in producing these parts with precision and global standards.

This in-depth guide answers key questions about metal selection, compares top materials, and shows how Prime supports critical infrastructure projects across industries.

What Is the Metal Most Used in Construction Industry?

Construction uses millions of tons of steel each year. Per World Steel Association, over 50% of global steel production supports building and infrastructure. Here’s why:

Carbon Steel: The Backbone of Buildings

- High strength-to-cost ratio

- Weldable, formable, and durable

- Compatible with concrete, wood, and stone

Common Applications

- I-beams, H-columns, rebar

- Roof connectors, joist hangers

- Railings, base plates, structural brackets

Prime supplies laser-cut, hot-dip galvanized, and CNC-drilled carbon steel parts meeting ASTM A36/A572 and EN 10025.

What Is the Most Useful Industrial Metal?

Industrial applications require metals that can handle stress, wear, and chemical exposure.

Steel—especially stainless and alloy variants—is the most versatile and useful metal across sectors.

| Metal Type | Key Benefits | Application Examples |

|---|---|---|

| Mild Steel | Easy to form and weld | Machinery frames, housings |

| Alloy Steel | High tensile and fatigue strength | Gears, axles, bushings |

| Stainless Steel | Corrosion and heat resistant | Piping, food-grade tanks, enclosures |

| Tool Steel | Wear resistant, thermal stability | Dies, molds, cutting tools |

Prime delivers precision-fabricated metal components for OEMs and integrators worldwide.

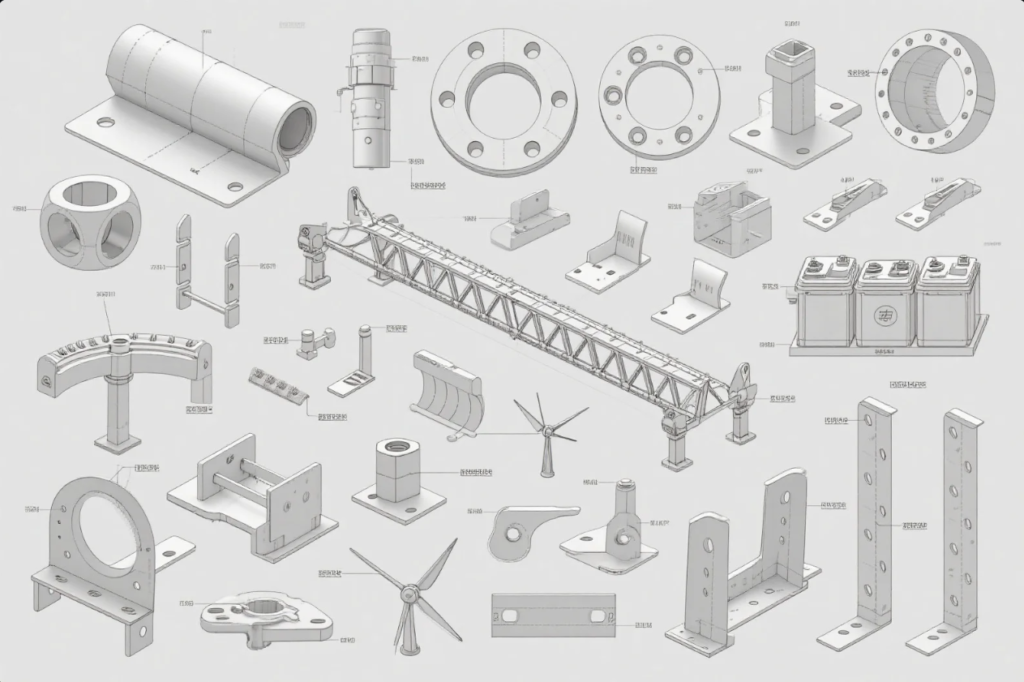

Which Type of Metal Is Better for Making Machinery?

Machinery often combines static support with dynamic motion. Materials must resist fatigue, heat, and shock.

Top Choices:

- 4140 Alloy Steel – Excellent fatigue strength

- 304/316 Stainless – Corrosion protection

- 6061/7075 Aluminum – Lightweight, high machinability

- Tool Steel (D2, H13) – Edge retention and surface hardness

Prime offers CNC precision up to ±0.005 mm, with surface finishes like passivation, black oxide, or anodizing.

Which Metal Is Most Widely Used in Industry and Building?

Steel remains the single most widely used metal in both infrastructure and manufacturing, according to the OECD Steel Committee.

Applications:

- Building frames, bridges, highway rails

- Wind turbine bases, energy plant supports

- Rail systems, bus chassis, solar structures

Prime delivers large-format brackets, plates, and weldments with global compliance—ISO, CE, RoHS, and more.

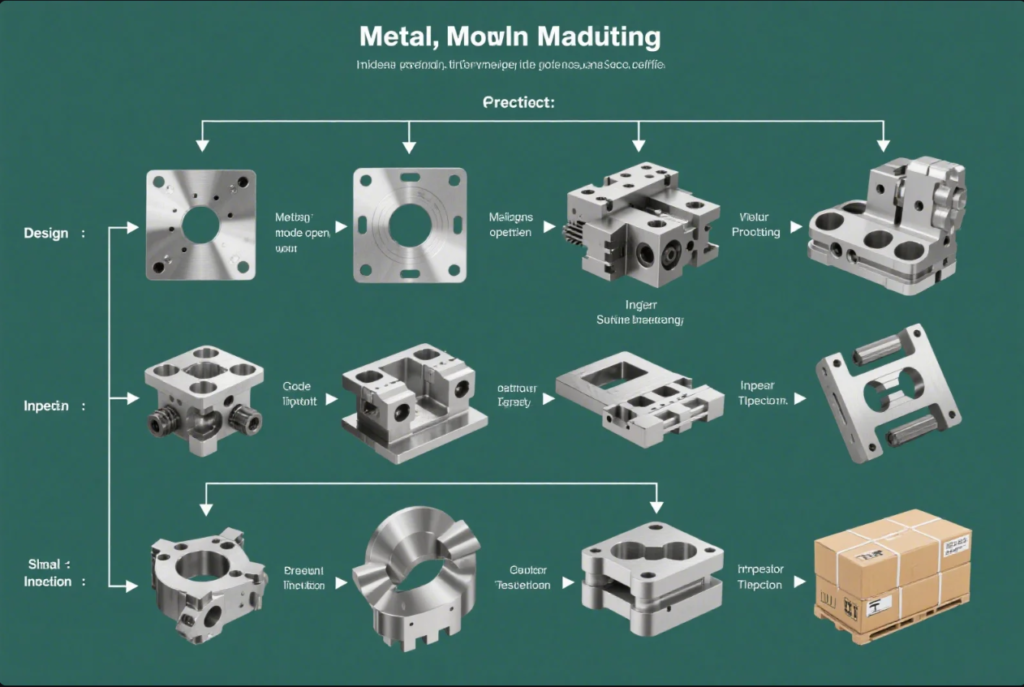

How Are Industrial Metal Parts Manufactured?

Prime’s 6-Step Workflow:

- Drawing Review – 2D/3D, DFM check

- Tooling/CNC – In-house dies or CAM program

- Sample + FAI – First Article, reports, material certs

- Mass Production – SPC control, weld inspections

- Surface Finish – Galvanizing, anodizing, polishing

- QA + Packaging – Barcoding, foam inserts, wood crates

All processes follow ISO 9001 and customer-specific specs. We export to over 40 countries.

Case Study 1: Wind Energy OEM – Tower Brackets

Challenge: Large welded brackets for wind turbines, tight delivery window.

Solution: MIG-welded 4-point parts with hot-dip galvanizing.

Result: 8000 brackets delivered in 21 days, 23% faster install time.

Case Study 2: Middle East Bridge Contractor

Challenge: 14 mm thick joint plates with powder coating.

Solution: Precision plasma cut, epoxy + polyurethane finish.

Result: All parts passed inspection; contractor awarded Phase 2 to Prime.

FAQs

1. Can I order without 3D drawings?

Yes. Sketches and samples are acceptable.

2. What certifications are available?

ISO 9001, RoHS, REACH, CE, PPAP (on request).

3. What is your MOQ?

We support low-volume prototyping and high-volume runs.

4. What are your lead times?

Tooling: 7–12 days. Production: 10–20 days.

5. Can I add my barcode or logo?

Yes. Laser, inkjet, or sticker options available.

6. How do you ship internationally?

By DHL, FedEx, air freight, or sea with full insurance.

Conclusion

Metal parts shape the world’s critical systems. Whether supporting a skyscraper or powering a turbine, choosing the right material and partner ensures safety and success.

📧 Get a quote from Prime at [email protected]

🌐 Visit https://primecustomparts.com for project support, drawings, and fast engineering feedback.

🔩 From raw steel to refined performance—Prime delivers custom metal parts on time, on spec, and built to last.

SEO Snippet (Google Featured Snippet Optimized)

Steel is the most used metal in construction and manufacturing. It is strong, affordable, and easy to fabricate. For machines and infrastructure, alloy and stainless steels offer corrosion resistance and fatigue strength. Prime supplies certified metal parts globally.