Best Welded Metal Parts Suppliers in 2025 for Industrial Applications?

I often faced weld quality issues. Then I realized choosing the right supplier matters. Here’s my step-by-step guide to finding top providers.

Snippet paragraph:

You encounter inconsistent welds, shipping delays, and damaged parts. This guide covers selection criteria, welding method comparisons (MIG, TIG, robotic), the benefits of ISO certification, and highlights Prime’s strengths.

Read on to explore key criteria, method analysis, certification importance, and Prime’s real-world capabilities.

What to Look for When Choosing a Welded Parts Manufacturer?

I faced late deliveries and weak welds in past projects. Then I realized what matters when selecting a welding supplier.

Snippet paragraph:

Your key criteria include quality certifications, welding expertise, customization capability, communication, packaging, logistics, pricing, and delivery time. These factors shape your success.

Key Factors for Supplier Selection

| Factor | Why It Matters | How to Judge |

|---|---|---|

| Quality Certifications | Ensures consistent quality and audit compliance | Request ISO 9001 or IATF 16949 certificates, and verify via registrar sites |

| Welding Experience | Influences weld strength and finish | Ask how many years they’ve welded industrial parts |

| Customization Ability | Supports part design variations | Check their tooling and engineering support |

| Communication | Drives clarity and reduces delays | Test response time during RFQ phase |

| Packaging & Logistics | Protects parts and meets delivery schedules | Confirm packaging standards and shipping tracking |

| Pricing & Lead Time | Affect cost and project timelines | Compare detailed quotes and delivery commitments |

Comparing Welding Techniques: MIG, TIG, and Robotic Welding?

I needed precise, strong welds for aluminum parts. So I tried MIG, TIG, and robotic welding. This is what I learned:

Snippet paragraph:

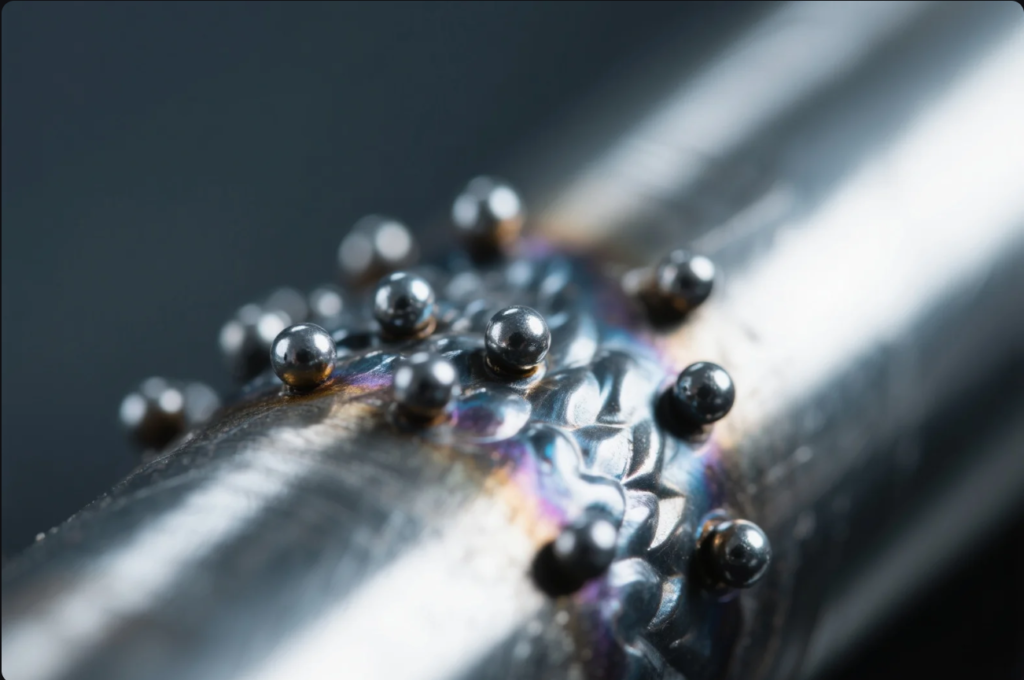

MIG welding offers speed and cost-effectiveness but needs cleanup. TIG gives precise, clean welds for thin metal. Robotic welding excels in repeatability and volume.

Welding Methods Compared

| Method | Benefits | Limitations | Ideal Applications |

|---|---|---|---|

| MIG Welding | Fast, high deposition, lower cost | Produces spatter, needs grinding | Thick parts and structural frames |

| TIG Welding | Clean, precise, low spatter | Slow and requires high skill | Thin metal, aerospace, medical parts |

| Robotic Welding | Consistent, fast, automated | High initial setup cost, less flexibility | High-volume, repetitive assemblies |

Learn more in this American Welding Society resource.

Why OEMs Prefer ISO-Certified Welded Assemblies?

OEM buyers often insist on ISO certification. I learned why that matters so much.

Snippet paragraph:

ISO-certified suppliers follow documented processes, traceability, and audits. This builds OEM trust and reduces risk.

- Documented operations reduce errors.

- Traceability tracks parts across batches.

- Continuous improvement cuts rework and defects.

- Global recognition simplifies supplier audits.

Visit ISO official welding standards for more on certification value.

PrimeCustomParts.com’s Capabilities in High-Precision Welded Fabrication?

I selected PrimeCustomParts.com after vetting several factories. Their capabilities matched top-tier needs.

Snippet paragraph:

Prime offers 10 welding lines, ISO certification, robust QC, and global shipping. They handle MIG, TIG, and robotic welding. Their tooling support ensures fast, precise results.

Vendor Comparison

| Comparison | PrimeCustomParts.com | Typical Small Vendor |

|---|---|---|

| ISO Certification | Yes – ISO 9001 | Often missing or outdated |

| Welding Lines | 10 | 1–3 |

| Welding Methods | MIG, TIG, Robotic | Usually MIG or TIG only |

| Tooling Support | In-house engineering | Rare or outsourced |

| Standard Lead Time | 2–4 weeks | 6–8 weeks or more |

| Packaging Standard | Foam + sealed crates | Basic cardboard |

| Communication | Daily updates | Inconsistent updates |

FAQs

What welding method is best for thin stainless parts?

TIG welding. It’s clean and precise. MIG is faster but rougher.

How can I verify ISO certification?

Ask for valid certificates. Cross-check on IQNet or JAS-ANZ.

Can Prime handle both prototypes and production?

Yes. They offer manual for prototypes, automated for volume.

What protects delicate parts in transit?

Foam trays, sealed crates, and desiccants for long shipping routes.

How long does tooling design take?

Typically 5–7 days for design, 2–3 weeks for build.

Can Prime ship worldwide?

Yes, via DHL, FedEx, MSC, and other carriers with full documentation.

📞 Contact Prime

Reach out now for a free consultation, quote, or tailored solution. We offer fast delivery, consistent quality, and stable global logistics.

Website: https://primecustomparts.com

Email: [email protected]

Conclusion

Choose suppliers with ISO certification, expert welding, and responsive communication. Prime delivers custom welded parts with speed and precision. Trust a certified partner to streamline your industrial production.