Can plastic parts be customized?

Many buyers ask if plastic parts can match their exact design or branding needs.

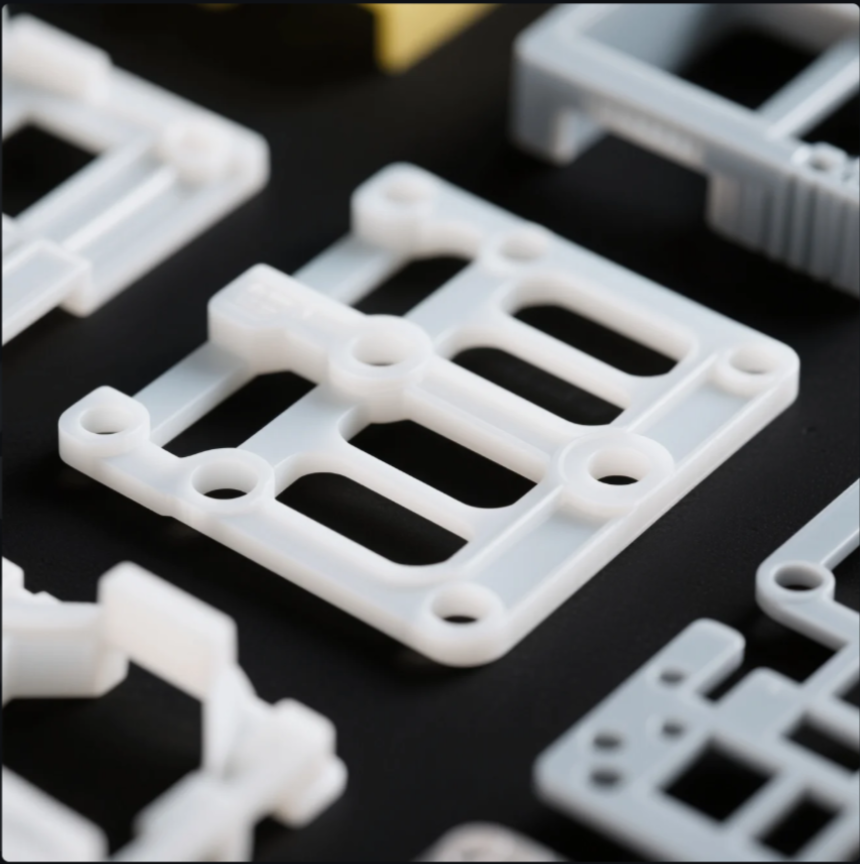

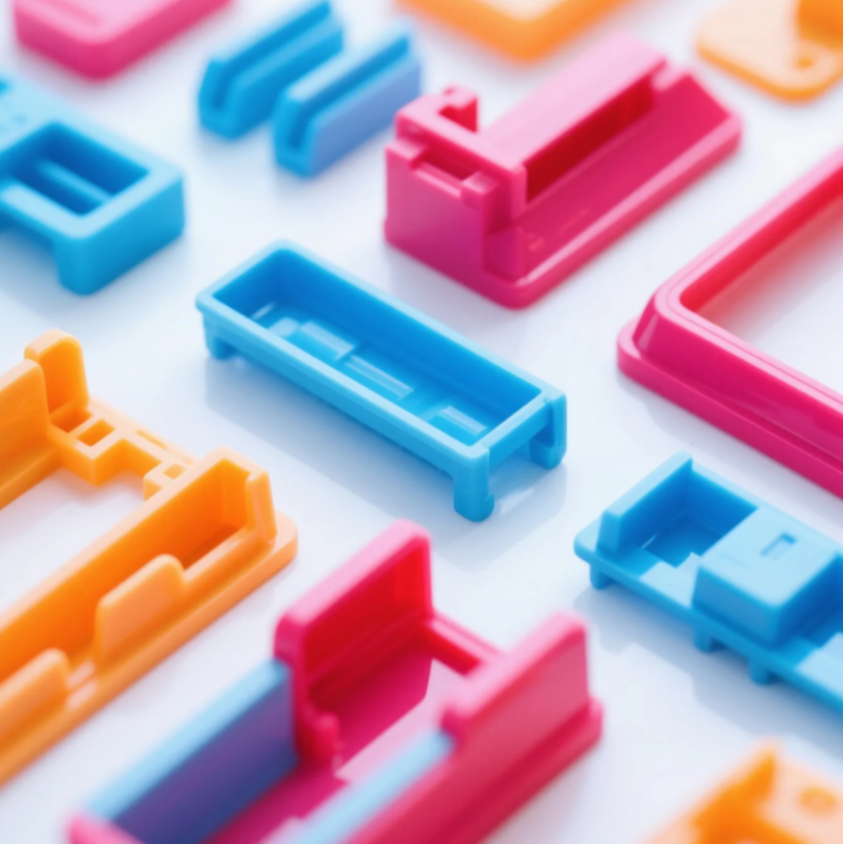

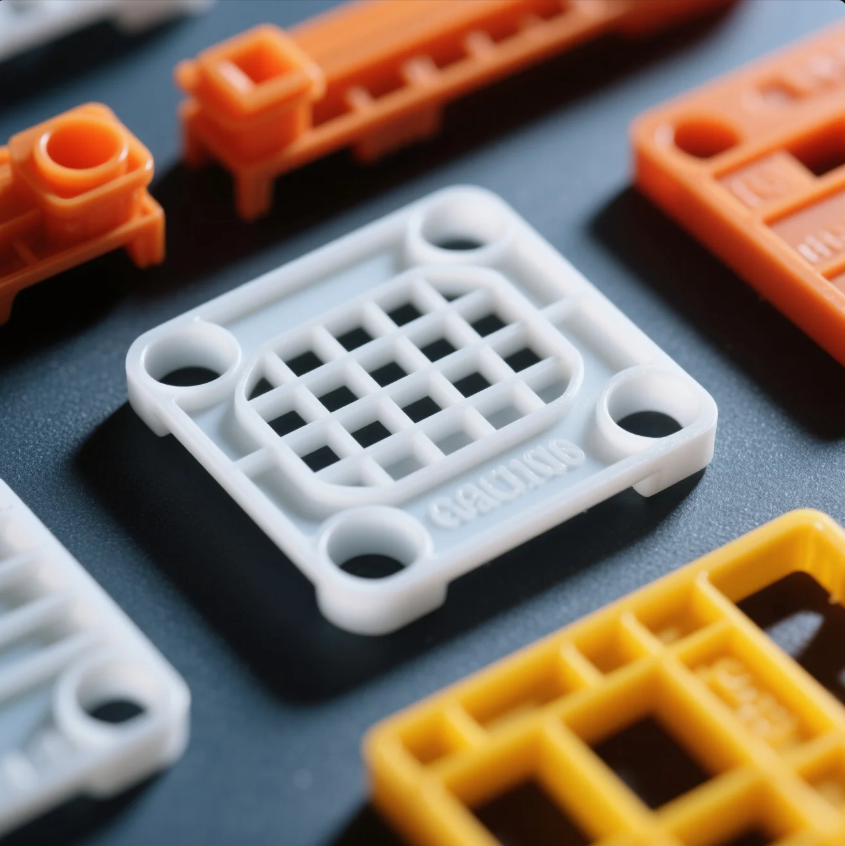

Yes, plastic parts can be fully customized in shape, color, size, function, and surface marking.

Customization helps improve product fit, function, and brand identity—when done right.

Let’s explore how custom plastic parts are made and what to consider at each step.

How to make a custom plastic part?

Clients often struggle with turning a concept into a real plastic part.

To create a custom plastic part, you need a 3D design, material selection, tooling, and a suitable manufacturing process.

Injection molding is the most common choice, especially for volume production.

Steps to Make a Custom Plastic Part

- Create a 2D sketch or 3D CAD file

- Select the right plastic resin

- Develop or modify the mold/tooling

- Test a prototype

- Run full-scale production

At Prime, we support clients from CAD to production. We offer rapid prototyping, mold design, and short-run manufacturing for new designs.

How do you reshape plastic parts?

Some buyers want to adjust parts post-production but aren’t sure how.

You can reshape plastic parts using heat forming, machining, or trimming, depending on the material type.

However, not all plastics allow reshaping once molded—especially thermosets.

Plastic Reshaping Methods

| Method | How It Works | Best For |

|---|---|---|

| Heat bending | Softens part using heat | Acrylic, PVC |

| CNC trimming | Removes excess or reshapes | ABS, PE, Nylon |

| Ultrasonic welding | Fuses parts together | PP, PE, PC, ABS |

At Prime, we provide secondary operations like trimming and surface correction to match your part’s final function or tolerance needs.

How to design a plastic product?

Clients often have product ideas but lack the technical path to turn them real.

Designing a plastic product starts with defining the function, choosing materials, and designing for manufacturability.

A bad design can cause costly tooling errors or product failure.

Key Plastic Design Tips

- Use consistent wall thickness

- Avoid sharp corners (stress risers)

- Include draft angles for easy ejection

- Choose materials based on temperature, strength, and chemical resistance

- Plan for assembly and marking from the start

Prime provides design-for-manufacturing (DFM) reviews to help clients optimize parts before tooling begins.

How do you mark plastic parts?

Branding or traceability is often required. Buyers ask how to add logos, codes, or lot numbers.

You can mark plastic parts through laser engraving, ink printing, embossing, or insert molding.

The right method depends on your volume, surface type, and durability needs.

Common Marking Techniques

| Method | Description | Best Use |

|---|---|---|

| Laser Engraving | Permanent, high precision | Serial numbers, logos |

| Pad Printing | Ink-based, fast and colorful | Mass branding, part labels |

| Embossing | Molded directly into the part | High volume logo marking |

| Insert Molding | Embedded metal/plastic labels | Certification or ID tags |

At Prime, we offer custom marking solutions integrated into the production process, helping you meet branding, safety, or legal requirements.

Conclusion

Plastic parts can be fully customized in design, shape, material, and branding. A smart design ensures performance and quality.

Looking for custom plastic part suppliers with full design-to-delivery support? Contact Prime today for a free quote, professional design help, and ISO-certified manufacturing that meets global standards.