Can you injection mold glass?

Many clients ask whether injection molding can be used with materials other than plastic — especially glass or ceramics.

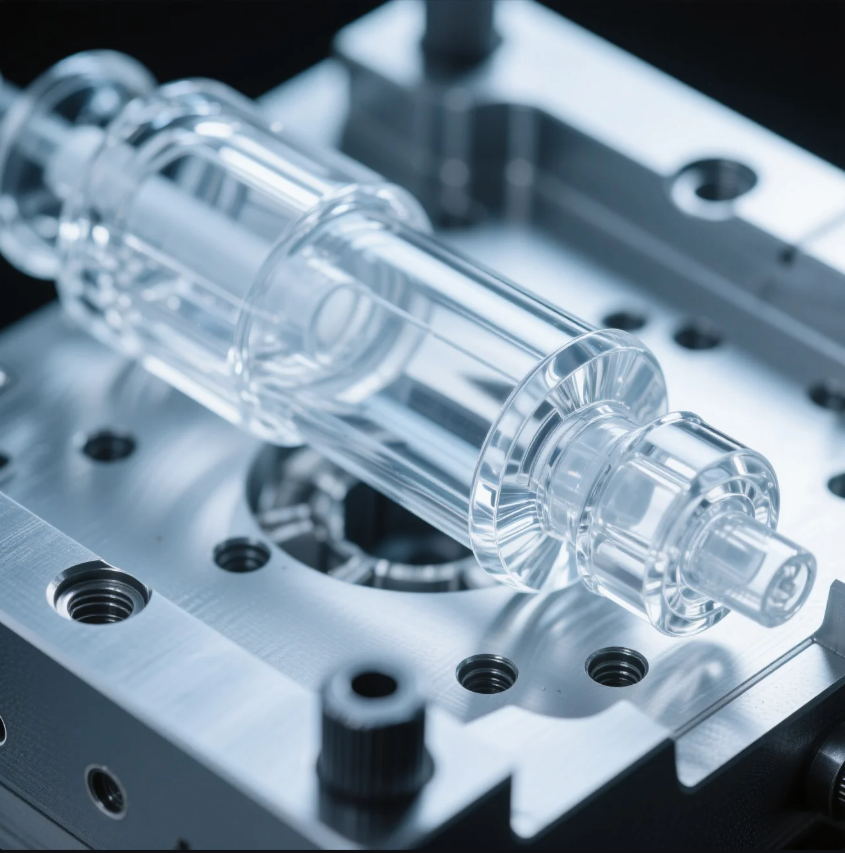

You cannot injection mold pure glass, but you can mold glass-filled plastics like nylon or polycarbonate using standard molding machines.

At Prime, we frequently work with glass-filled thermoplastics to produce durable, high-strength custom plastic parts for industrial use.

Can glass be injection moulded?

Pure glass cannot be injection molded using standard plastic molding machines due to its extreme melting point.

No — glass cannot be injection molded like thermoplastics. It requires glassblowing, casting, or pressing techniques.

Glass melts at over 1400°C — far above the safe operating range of injection molding machines. Molds used for glass also require special materials and cooling methods, making the process completely different from plastic molding.

Why Glass Can’t Be Injection Molded

| Property | Glass | Plastic |

|---|---|---|

| Melting point | \~1400–1600°C | \~180–300°C |

| Flow behavior | Viscous and unstable | Predictable, controlled |

| Molding method | Blown, cast, pressed | Injection molded |

Instead, engineers use glass-filled thermoplastics to combine glass strength with plastic processability — something Prime specializes in.

Can you injection mold glass filled nylon?

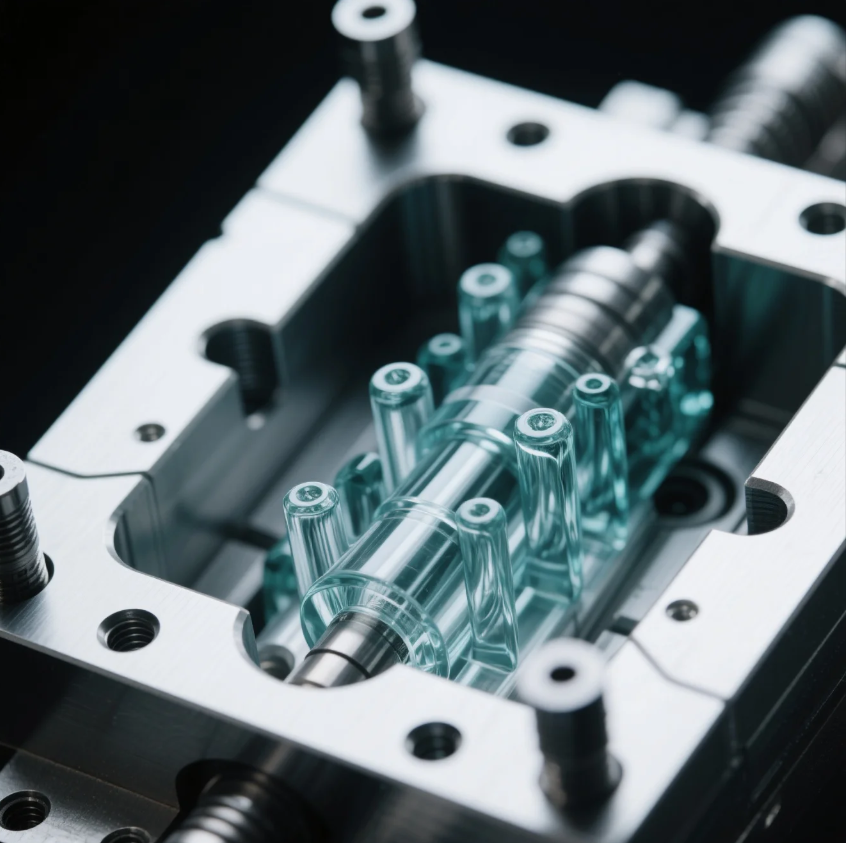

Glass-filled nylon is widely used in automotive, electronics, and structural parts — and is injection moldable.

Yes — glass-filled nylon is one of the most popular engineering plastics for injection molding.

We mold thousands of glass-reinforced parts at Prime every month. One client needed heat-resistant structural clips. We used 30% glass-filled nylon (PA6 GF30) for strength and thermal stability.

Benefits of Glass-Filled Nylon

| Feature | Performance |

|---|---|

| Strength | 30–50% stronger than standard nylon |

| Heat resistance | Improved dimensional stability |

| Cost | Affordable vs. metal components |

| Moldability | Excellent in standard molds |

Prime helps clients choose the right grade, fill percentage, and mold design for reinforced plastic parts.

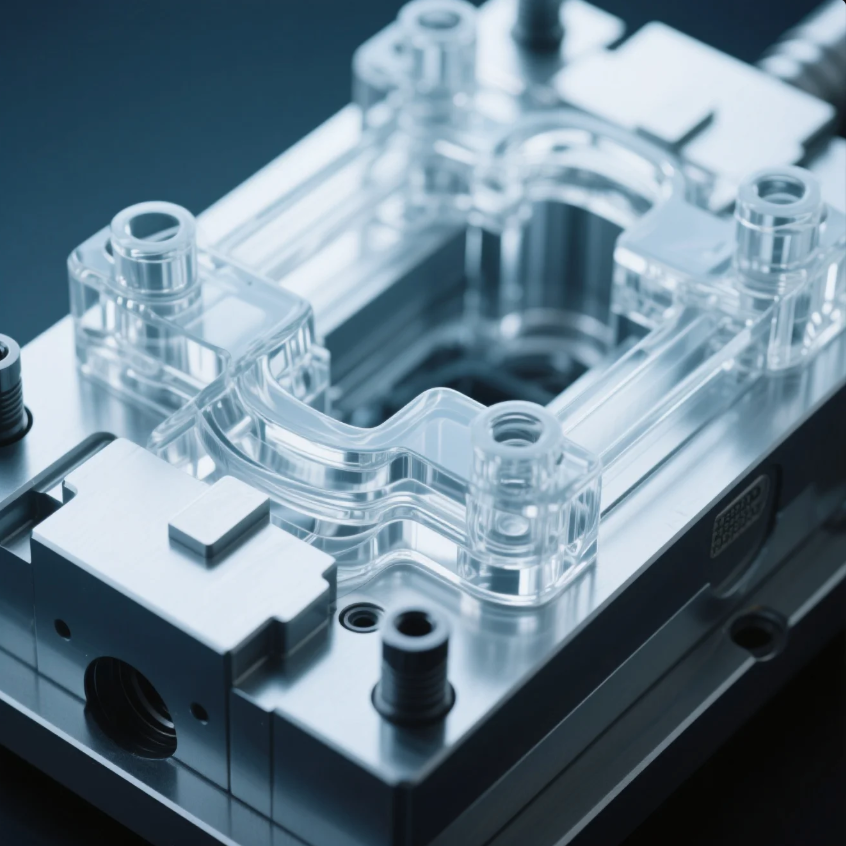

Is injection molding only for plastic?

Most people associate injection molding with plastic — but variations exist.

Standard injection molding is for plastics, but metal and ceramic injection molding (MIM and CIM) are also possible using specialized equipment.

One of our U.S. clients asked about using injection molding for small metal hinges. We explained the difference — then helped them design a plastic replacement using glass-filled polyamide, reducing cost and weight.

Molding Material Options

| Material Type | Can Be Injection Molded? | Notes |

|---|---|---|

| Thermoplastics | Yes | Standard process |

| Thermosets | Limited | Specialized equipment required |

| Metals (MIM) | Yes (special equipment) | Fine metal powders + binder |

| Ceramics (CIM) | Yes (advanced method) | Pre-sintered ceramic compounds |

At Prime, we focus on plastic and composite molding — offering durable, lightweight alternatives to metal and ceramic parts.

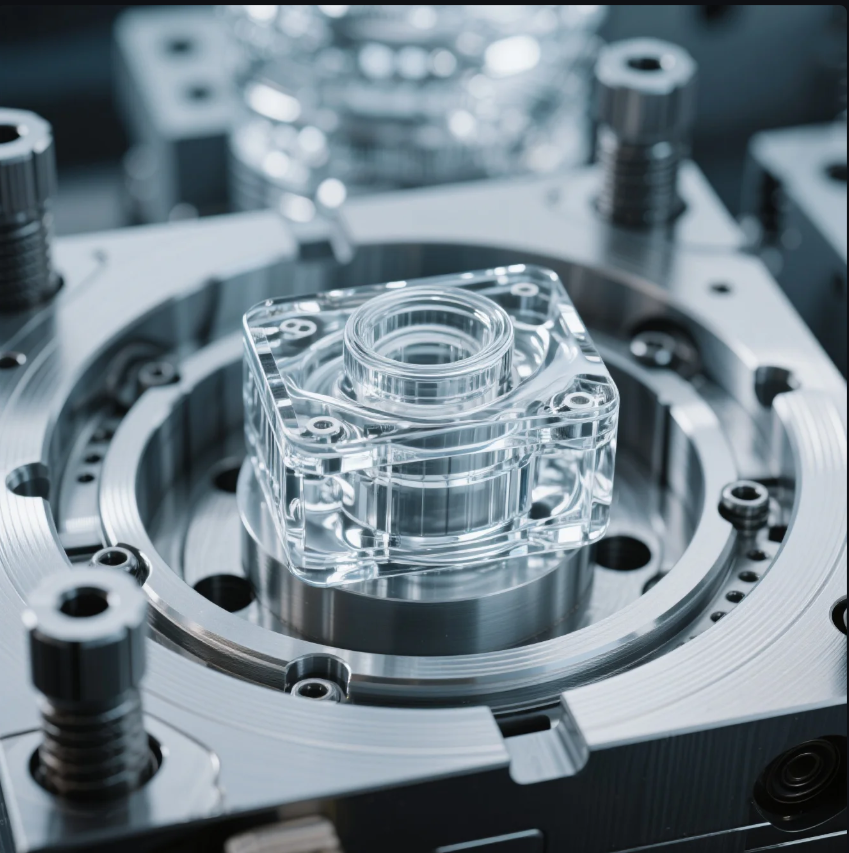

Can you injection mold ceramics?

Ceramics may seem impossible to mold, but modern processes allow it in some cases.

Yes — ceramics can be injection molded using a method called Ceramic Injection Molding (CIM), but it requires special feedstock and post-processing.

We don’t mold ceramics at Prime, but we often design plastic substitutes that replicate ceramic function — faster and cheaper. One client needed high-wear washers. We used 50% glass-filled PEEK instead, offering both stiffness and heat resistance.

Ceramic Injection Molding (CIM)

| Stage | Description |

|---|---|

| Feedstock prep | Ceramic powder mixed with binder |

| Injection molding | Uses high-pressure mold cavity |

| Debinding | Binder is chemically removed |

| Sintering | Final part is baked at high temperature |

Due to its cost and complexity, CIM is used in aerospace, medical, and microelectronics — not common for general-purpose parts.

Conclusion

You can’t injection mold pure glass — but glass-filled plastics like nylon or PC are ideal for high-strength applications.

Need high-performance glass-filled plastic parts or unsure which material suits your design? Prime offers free material selection help, part cost estimates, and fast global production. Contact us now for expert support and reliable ISO-certified injection molding.