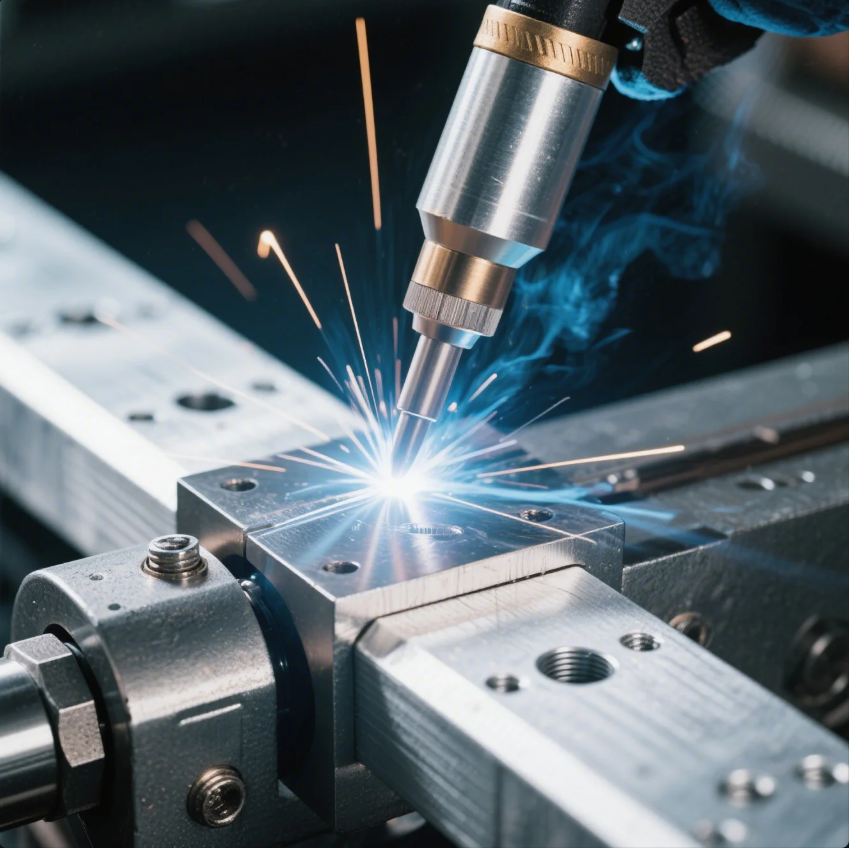

Can You Stick Weld Aluminum?

Aluminum is tricky. The wrong welding method causes cracking, porosity, and weak joints.

Yes, you can stick weld aluminum, but it’s difficult, messy, and often not recommended.

Let’s dive into when—and if—you should stick weld aluminum, and explore better alternatives for quality results.

What rod to stick weld aluminum?

Not all rods work on aluminum—most are made for steel or cast iron.

You must use special aluminum electrodes like E4043 or E5356 to stick weld aluminum.

Aluminum welding rods: What you need to know

If a client tells me they want to stick weld aluminum, I always explain the limitations first. Then, I recommend the correct rod based on the job.

Most used aluminum stick rods:

- E4043 – Best all-purpose, smoother arc

- E5356 – Higher strength, better for marine applications

But here’s the catch: aluminum has a low melting point and high thermal conductivity. That makes it easy to burn through with stick welding.

Also, slag inclusion and porosity are much more likely in stick welds on aluminum than with MIG or TIG.

Table: Common Aluminum Stick Electrodes

| Electrode Type | Strength | Weld Appearance | Typical Use |

|---|---|---|---|

| E4043 | Medium | Smooth, clean | General-purpose aluminum |

| E5356 | High | Slightly rougher | Marine, structural aluminum |

At Prime, we almost never use stick for aluminum. We prefer TIG or MIG with proper shielding for clean, strong, and certified welds.

Is stick weld stronger than MIG?

Strength isn’t about the method—it’s about control and application.

No, stick welding is not inherently stronger than MIG. MIG offers better consistency and cleaner penetration.

Strength: MIG vs. Stick

In real-world factory environments, MIG delivers better strength on average, especially for repeatable, high-volume welds. Why?

- Cleaner arc and better fusion

- Less spatter and slag

- Easier to control heat and travel speed

Stick welding can penetrate deeply and works better on rusty or dirty metal. But its manual nature makes it less consistent than MIG, especially in aluminum welding.

Table: Welding Strength Comparison

| Method | Average Strength | Control Level | Application Fit |

|---|---|---|---|

| MIG | High | High | Fabrication, aluminum, sheet metal |

| Stick (SMAW) | Medium-High | Moderate | Outdoor, heavy steel |

| TIG | Very High | Very High | Precision, aerospace |

At Prime, we match the method to the job. For structural components, we often use robotic MIG. For tight tolerances, we recommend certified TIG welding.

What is the best method for welding aluminum?

Aluminum needs finesse—too much heat ruins the job.

TIG welding is the best method for aluminum, but MIG works well for thicker parts.

Why TIG is the top choice for aluminum welding

Aluminum reacts fast to heat. That’s why TIG welding—with its clean arc, fine control, and low heat input—gives the best results.

However, for clients building large panels, frames, or aluminum boxes, we recommend MIG with a spool gun, which speeds up production without sacrificing quality.

Key considerations:

- TIG – Best for precision and thinner materials

- MIG (spool gun) – Best for thicker aluminum sections and speed

- Stick – Poor fit unless in extreme field repair cases

Table: Welding Methods for Aluminum

| Method | Best For | Surface Prep Required | Skill Level |

|---|---|---|---|

| TIG | Thin aluminum, clean joints | Very high | Advanced |

| MIG | Medium-thick parts | Moderate | Intermediate |

| Stick | Emergency repair only | Moderate | Hard |

When clients come to Prime needing aluminum parts, we ask about the part thickness and tolerances, then choose TIG or MIG. We also offer custom aluminum CNC blanks for better welding performance.

What’s the easiest welding to learn?

For new welders, setup and cleanup make all the difference.

MIG welding is the easiest type to learn, thanks to its semi-automatic process.

MIG is beginner-friendly—and practical

When someone on a client’s team is new to welding, I suggest MIG first. It requires less coordination, produces cleaner results, and works well for common materials like mild steel and aluminum.

You just aim the gun, adjust the speed and voltage, and go. Stick welding, by comparison, needs more finesse and arc control.

Beginner benefits of MIG:

- Wire fed automatically

- Minimal slag

- Great visibility of the weld puddle

Table: Learning Curve by Welding Type

| Welding Type | Learning Difficulty | Cleanup Required | Ideal For |

|---|---|---|---|

| MIG | Low | Low | Beginners, fabrication |

| Stick (SMAW) | Medium | High | Repairs, outdoors |

| TIG | High | Low | Precision, thin metal |

At Prime, we help new buyers and their teams set up MIG stations and provide pre-cut CNC aluminum parts to make learning easier.

Conclusion

Yes, you can stick weld aluminum—but better, faster, and stronger methods exist for most projects.

Want expert-welded aluminum parts without the learning curve or mess?

Contact Prime today for precision-welded solutions, fast delivery, and free consultation.

We ship globally and offer ISO-certified welding services trusted by industrial clients worldwide.

Send an inquiry now—let’s build your solution together.