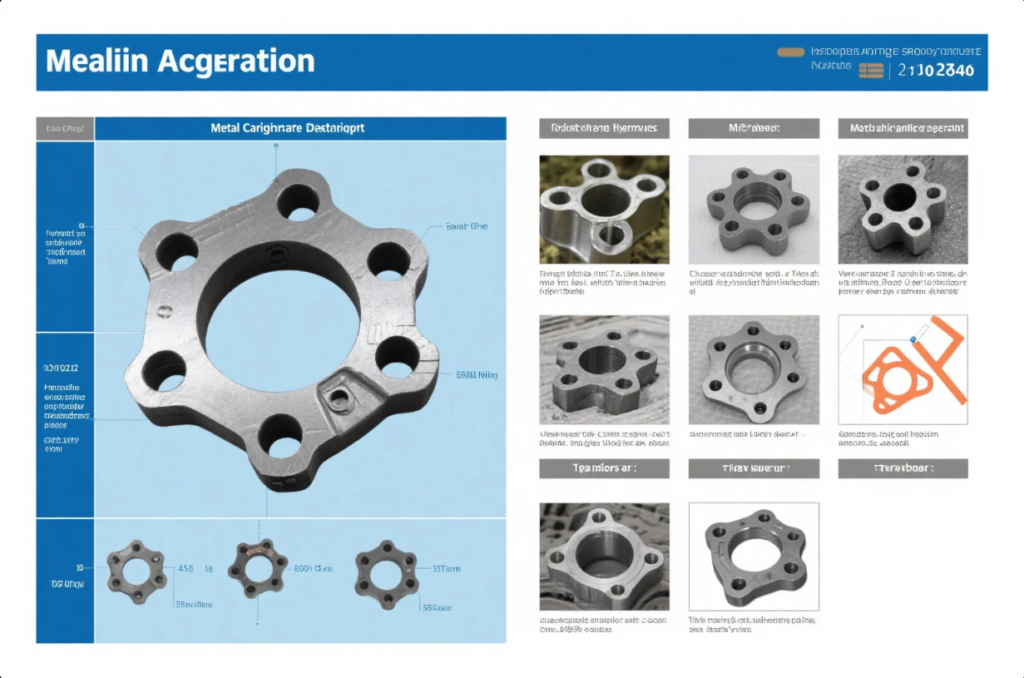

Selecting the Right Alloy for Metal Casting Applications

Selecting the Right Alloy for Metal Casting Applications Choosing the right alloy is a critical step in the metal casting process. The selected material affects not only the strength and durability of the final part but also factors such as cost, machinability, corrosion resistance, and weight. Whether you’re casting automotive components, electronic housings, or structural […]

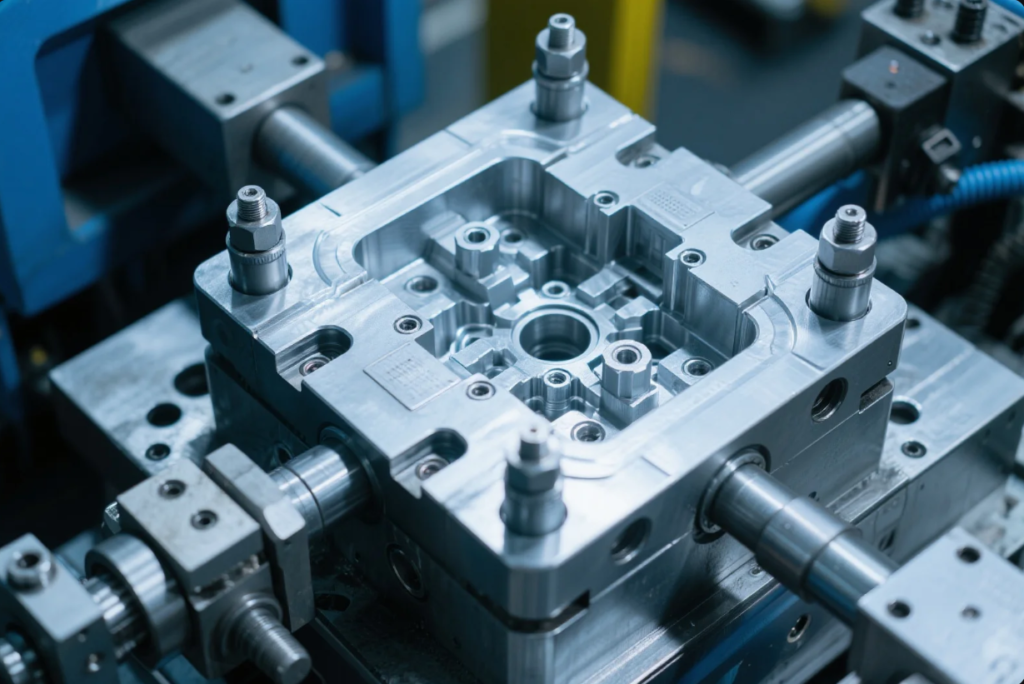

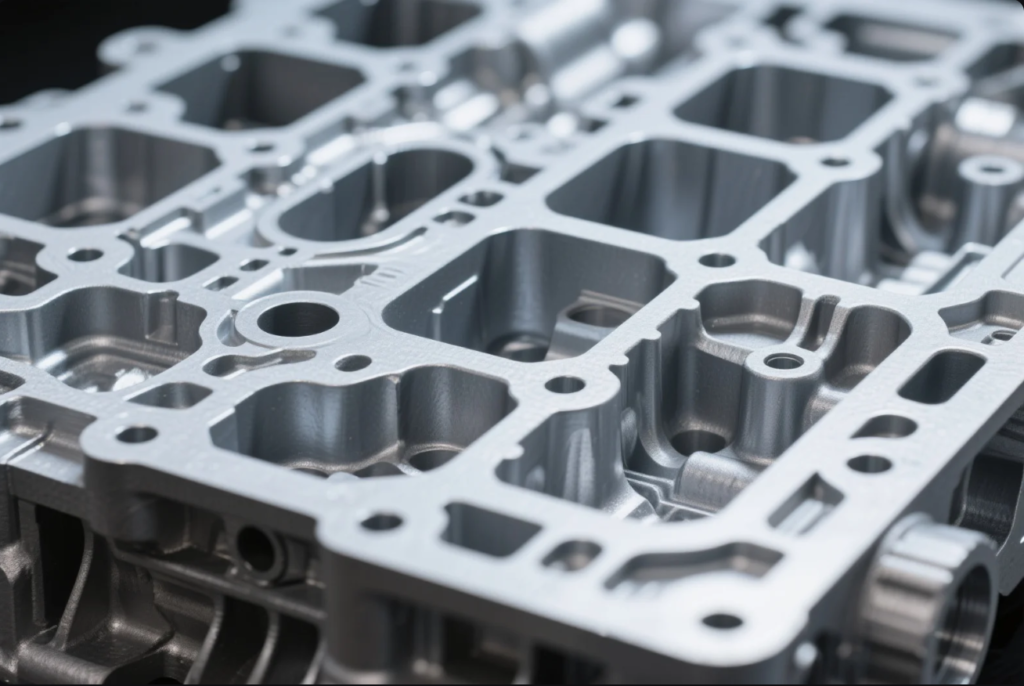

Centrifugal & High Pressure Casting: Heavy‑Duty Metal Solutions

Centrifugal & High Pressure Casting: Heavy‑Duty Metal Solutions When it comes to manufacturing dense, high-strength metal components, centrifugal casting and high-pressure casting offer distinct advantages for industrial applications. These two methods are essential for producing parts with superior mechanical properties, dimensional precision, and material integrity—especially in sectors like automotive, aerospace, and heavy machinery. This guide […]

Investment Casting Explained: Achieving Miniature & Intricate Designs

Investment Casting Explained: Achieving Miniature & Intricate Designs Investment casting—also known as lost wax casting—is a manufacturing method renowned for its ability to produce intricate, miniature, and high-precision components. It allows for the production of parts with tight tolerances, fine surface finishes, and complex geometries that are often difficult or impossible to achieve through other […]

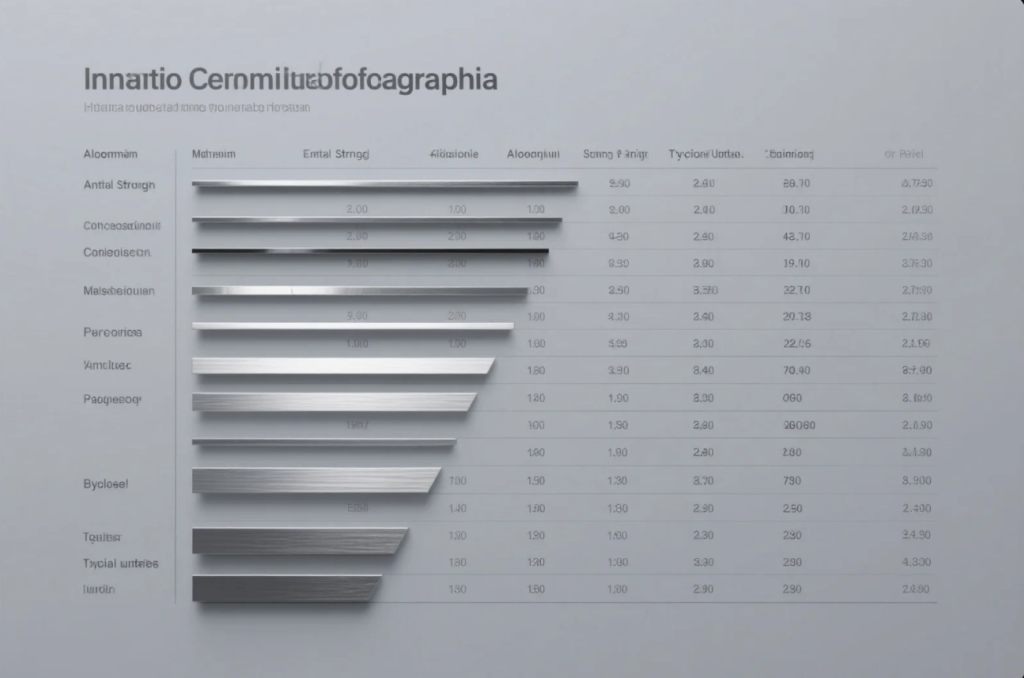

Precision Casting (Lost Wax) vs Die Casting: What to Choose?

Precision Casting (Lost Wax) vs Die Casting: What to Choose? When it comes to producing high-quality metal components, two widely used casting methods often stand out: Precision Casting (also known as Lost Wax Casting) and Die Casting. Each has distinct strengths depending on the project’s requirements in terms of complexity, volume, cost, and performance. This […]

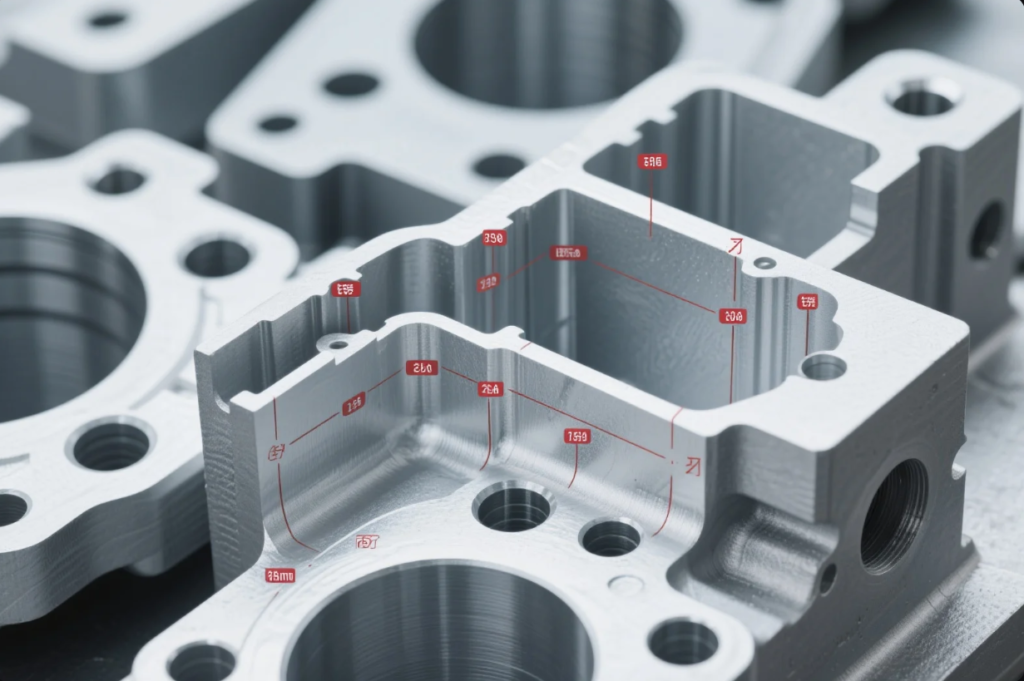

Understanding Sand Casting for Complex Metal Parts

Understanding Sand Casting for Complex Metal Parts Sand casting is one of the oldest yet most versatile metal forming processes in modern industry. Known for its simplicity and adaptability, sand casting is widely used to produce complex metal parts for various industries including automotive, aerospace, energy, and heavy equipment. This in-depth guide explores how sand […]

The Best Custom Metal Casting Manufacturers: Top 7 Industry Leaders You Should Know

The Best Custom Metal Casting Manufacturers: Top 7 Industry Leaders You Should Know What are the largest metal casting companies? Leading global casting firms include Thyssenkrupp AG, Alcoa Corporation, Arconic Inc., GE Aviation, and prominent North American players like Signicast, Dynacast International, and MetalTek International ([en.wikipedia.org][1]). These companies set industry benchmarks in capacity, innovation, and specialization. […]

Leading Custom Metal Casting Suppliers: Top 5 Companies for High-Quality Parts

Leading Custom Metal Casting Suppliers: Top 5 Companies for High‑Quality Parts Industry Landscape and Market Leaders The metal casting industry spans diverse applications—from heavy machinery, automotive, aerospace to energy and defense. In 2024, global casting output totaled over 90 million metric tonnes, led by: Signicast (investment casting) and Dynacast International (precision die casting) in North America […]

Top 10 Custom Metal Casting Parts Manufacturers for Precision Components in 2025

Top 10 Custom Metal Casting Parts Manufacturers for Precision Components in 2025 Which is the most widely used metal for casting? Gray iron is the most used casting metal worldwide. It’s affordable, easy to machine, and offers excellent vibration damping. Typical applications include automotive engine blocks and industrial machinery bases. Aluminum is also widely used. […]

Top-Rated Custom Casting Suppliers in China: Quality, Capacity, and Price

Top-Rated Custom Casting Suppliers in China: Quality, Capacity, and Price? Low price alone can’t guarantee quality. Many buyers lose time and money on unreliable casting suppliers. Top-rated Chinese casting suppliers combine ISO quality, strong capacity, and global pricing competitiveness. If you’re searching for trusted partners, this guide will show who leads in 2025—and what to […]

Top Global Foundries Specializing in Custom Metal Castings and Components

Top Global Foundries Specializing in Custom Metal Castings and Components? Delays, defects, and unclear specs—these are common issues when sourcing castings globally. The best global foundries provide certified metal castings with reliable delivery, engineering support, and full customization. Let’s explore how top foundries solve your biggest casting challenges and which suppliers lead in 2025. What […]