Does CNC require coding?

Does CNC Require Coding? At Prime’s manufacturing facility, we’ve found that 90% of our CNC operations use visual programming interfaces rather than manual coding – our operators typically generate toolpaths through CAD/CAM software that automatically creates the necessary G-code, making direct coding knowledge optional for most applications. Snippet paragraph: While CNC fundamentally relies on G-code […]

What is the easiest CNC software for beginners?

What Is the Easiest CNC Software for Beginners? Your Stress-Free Guide At Prime’s training center where we onboard 120 new CNC operators annually, we’ve found Autodesk Fusion 360 strikes the best balance between approachability and functionality – with 82% of trainees achieving basic proficiency within their first 8 hours thanks to its guided workflows and […]

Is CNC faster than 3D printing?

Is CNC Faster Than 3D Printing? The Speed Comparison Breakdown At Prime’s manufacturing facility with both 15 CNC machines and 8 industrial 3D printers, we’ve found CNC typically completes metal parts 3-5x faster than comparable 3D printed versions – our aluminum bracket that takes 22 minutes via CNC requires 4.5 hours to 3D print in […]

What software does CNC use?

What Software Does CNC Use? The Complete Toolchain Explained At Prime’s 10-production-line facility, we utilize a specialized software ecosystem for CNC operations – from CAM programming to machine control and simulation – with our workflow integrating 8 different software types that collectively transform CAD designs into precision machined parts in as fast as 72 hours […]

Is CNC only for metal?

Is CNC Only for Metal? The Multi-Material Machining Revolution Contrary to common perception, CNC technology machines far more than just metals—at Prime, we daily process 17 material types including engineering plastics, woods, and composites with our 32 multi-purpose CNC centers, proving its versatility beyond traditional metalworking with projects ranging from Delrin gear prototypes to carbon […]

Is CNC the same as CAD?

Is CNC the Same as CAD? The Critical Differences Explained While CNC (Computer Numerical Control) and CAD (Computer-Aided Design) both power modern manufacturing, they serve fundamentally different purposes—CAD creates the digital blueprint (we use SOLIDWORKS to design 300+ parts monthly), while CNC executes the physical production (our machines transform those designs into tangible products with […]

What does CNC cut stand for?

What Does CNC Cut Stand For? The Precision Machining Breakthrough Explained When manufacturers mention CNC cutting, they’re referencing Computer Numerical Control – the technology that revolutionized machining by converting digital designs into physical parts with 0.01mm accuracy. At Prime Factory, our 15 CNC centers process over 20,000 components monthly, transforming raw materials into aerospace brackets, […]

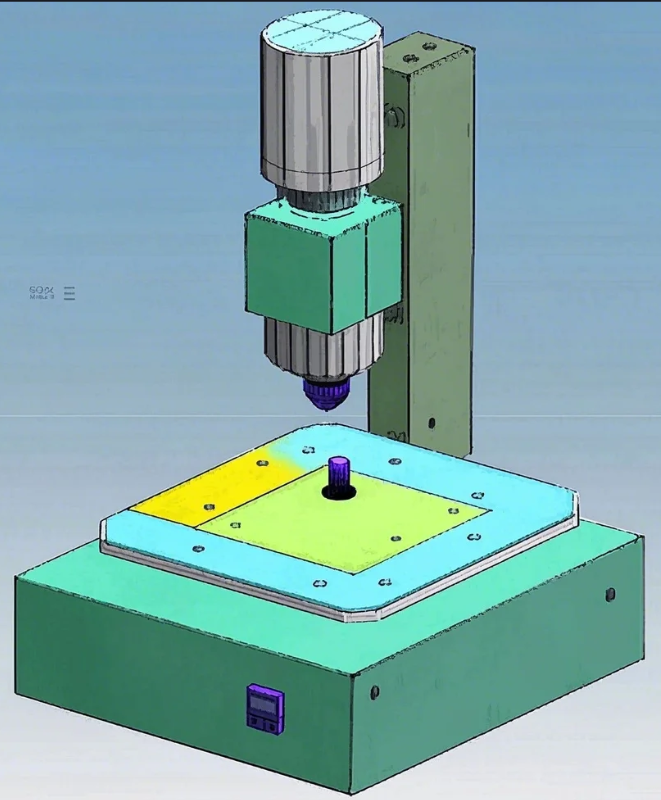

What is CNC machining? One minute to read the precision machining process

What is CNC Machining? A 1-Minute Guide to Precision Manufacturing CNC machining creates custom metal/plastic parts with unmatched accuracy. In Prime’s 30-year experience, this process delivers ±0.005mm tolerances – essential for aerospace, automotive, and medical industries. CNC (Computer Numerical Control) machining uses programmed software to automate cutting tools, transforming raw blocks into complex parts with […]

What is the difference between CNC milling and cutting?

TEMPLATE_START CNC Milling vs. Cutting: What’s the Real Technical Difference? After processing over 50,000 orders, we’ve identified exact scenarios when clients should choose milling over other cutting methods – it often comes down to needed precision (±0.001") versus production speed. Critical distinction: CNC milling uses rotating multi-point tools for 3D material removal (adds pockets, slots, […]

What does CNC mean in cutting?

What Does CNC Really Mean in Modern Cutting Technology? After running CNC operations since 1998, we’ve seen how Computer Numerical Control revolutionized cutting – achieving tolerances impossible with manual methods while boosting productivity 300-500%. CNC cutting means: 1) Computer-guided tool paths 2) Pre-programmed dimensions (typically within ±0.005") 3) Automated material removal 4) Repeatable processes – […]