How Are Metal Stamping Parts a Cost-Effective Choice?

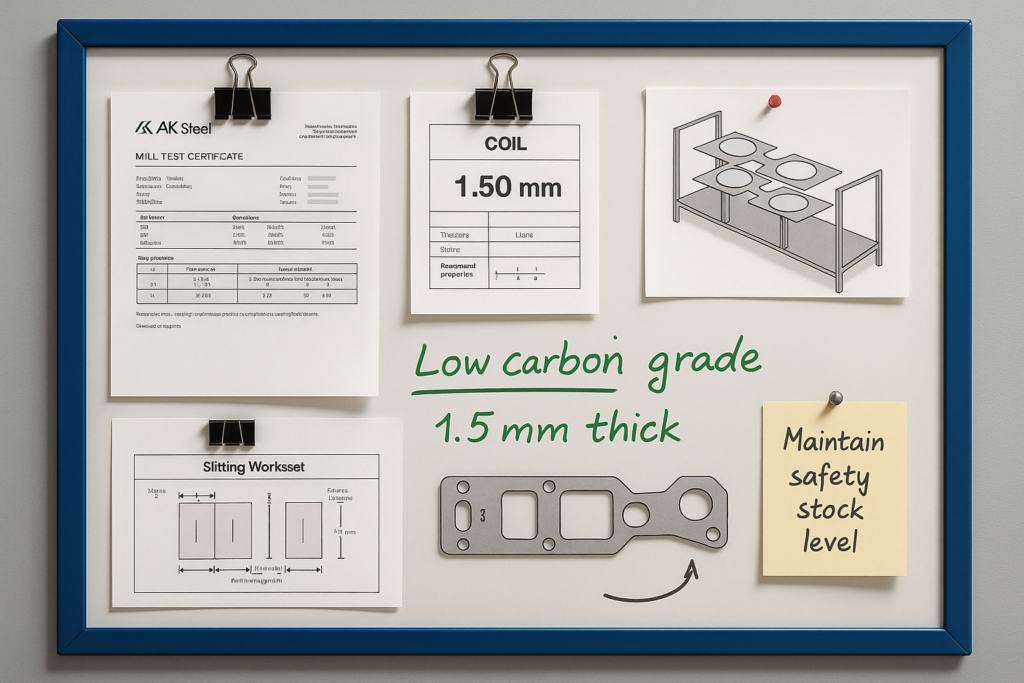

How Are Metal Stamping Parts a Cost-Effective Choice? Budgets tighten. Launch dates slip. I show clear actions that protect cash1, quality, and time. Metal stamping cuts total cost when teams align design, materials, tooling, QC, and logistics. Progressive dies reduce handling and scrap. Standard grades and early DFM stabilize price and yield. In-house tooling shortens […]

Top 7 Proven Ways to Reduce Tooling Costs in High-Volume Metal Stamping?

Top 7 Proven Ways to Reduce Tooling Costs in High-Volume Metal Stamping? Tooling drains profit fast. Deadlines slip. I use seven proven moves to protect margin. High-volume buyers cut tooling cost1 by aligning design, material, and process early. Teams choose the right die strategy2 and commit volume gates. Suppliers then build simpler tools, run faster […]

Why Custom Metal Molds Are Critical for High-Precision Manufacturing in 2025

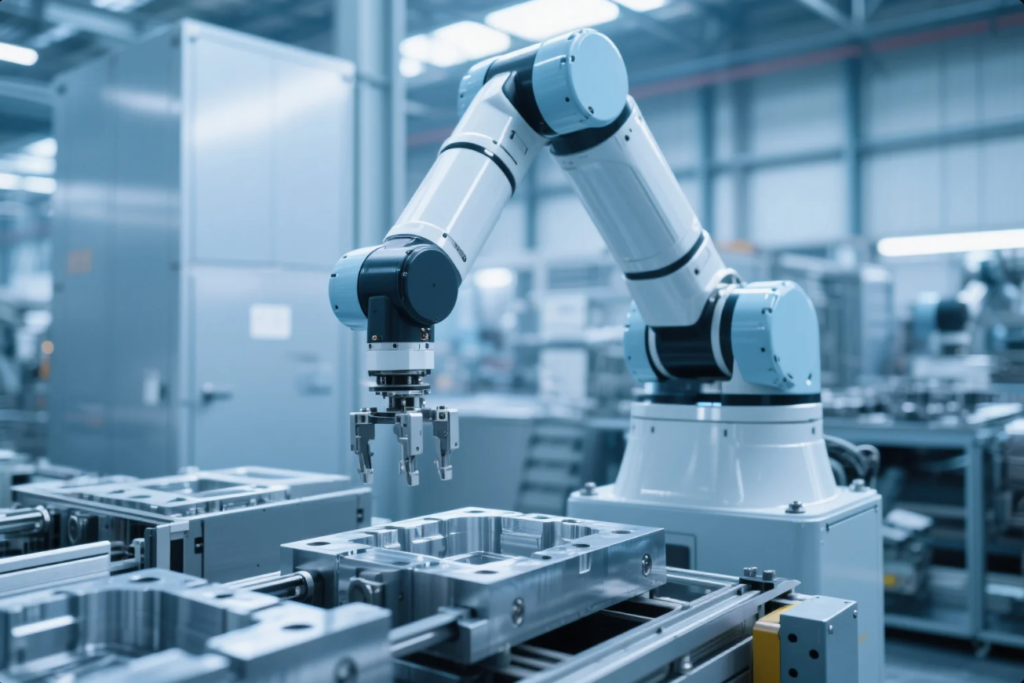

Why Custom Metal Molds Are Critical for High-Precision Manufacturing in 2025? As tolerances shrink and demand for miniaturized components grows, generic molds fall short. Manufacturers face rising defects and inefficiency. Custom metal molds meet the demands of high-precision production in 2025—supporting miniaturization, automation, and zero-defect output. This article explores what molds are, how they differ […]

Top Uses of Custom Metal Molds in Aerospace

Top Uses of Custom Metal Molds in Aerospace, Medical, and Energy Sectors? Precision and consistency define high-stakes sectors like aerospace, medical, and energy. Generic molds can’t meet their tolerances or performance demands. Custom metal molds ensure part uniformity, structural integrity, and regulatory compliance in these mission-critical industries. This guide explores how precision mold technology supports […]

Best Custom Metal Mold Solutions for Electronics and Consumer Goods in 2025

How Custom Metal Molds Improve Efficiency in Industrial Production Lines? Unoptimized tools create waste, cycle delays, and line failures. As production demand grows, generic tooling can’t keep up. Custom metal molds improve productivity by ensuring repeatability, faster cycles, and stable part quality in industrial environments. In this article, I’ll walk through the key reasons tooling […]

How Custom Metal Molds Improve Efficiency in Industrial Production Lines

How Custom Metal Molds Improve Efficiency in Industrial Production Lines? Industrial manufacturers lose millions yearly from delays, rejects, and inefficient tooling. Poor mold design slows production and inflates costs. Custom metal molds ensure repeatability, reduce cycle time, and improve process stability across industrial sectors. This article explores how molds impact efficiency, which fabrication methods apply, […]

Top Applications of Custom Metal Molds in Automotive Manufacturing 2025

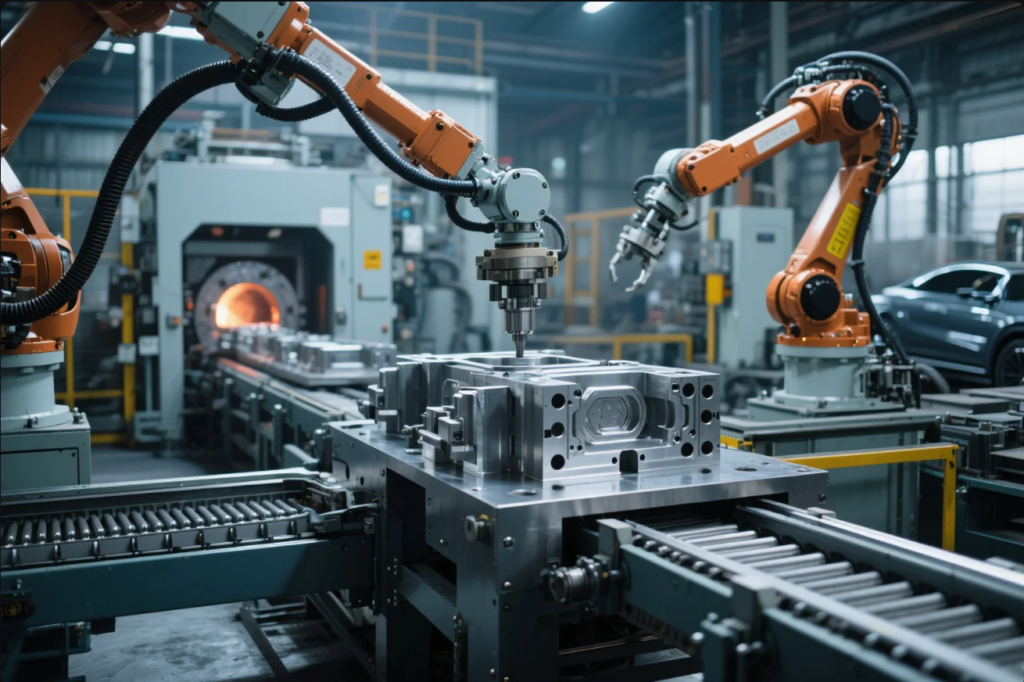

Top Applications of Custom Metal Molds in Automotive Manufacturing 2025? Automotive manufacturers demand lightweight, durable, and precision-fit parts. Inconsistent molds lead to misalignment, waste, and costly recalls. Custom metal molds ensure dimensional accuracy, repeatability, and strength across key automotive systems. In 2025, their role is more vital than ever. This guide explains how metal molding […]

Top 8 Custom Metal Mold Applications for High-Volume Manufacturing in 2025

Top 8 Custom Metal Mold Applications for High-Volume Manufacturing in 2025? Manufacturers in 2025 face growing pressure: more output, less waste, and tighter tolerances. For that, they need custom molds designed for efficiency. Custom metal molds are the foundation of high-volume production. They enable fast, repeatable, cost-effective manufacturing across industries. In this guide, I’ll share […]

Top Custom Metal Mold Solutions for Medical Device Production

Top Custom Metal Mold Solutions for Medical Device Production in 2025? Medical device makers face strict precision, cleanliness, and regulatory pressure. Poor mold quality risks compliance and patient safety. Custom metal molds are vital for high-precision, certified medical components. In 2025, accuracy and cleanliness are non-negotiable. Let’s explore top materials, mold maker demand, manufacturing definitions, […]

2025 Guide: Top Industrial Applications of Custom Metal Molds

2025 Guide: Top Industrial Applications of Custom Metal Molds? Global manufacturers seek durable, repeatable solutions. Poorly designed molds cause costly downtime. Custom metal molds help industries produce precision parts at scale. They improve repeatability, strength, and design flexibility. This 2025 guide explores key mold processes, their future outlook, casting types, and how to create your […]