Cylinder Neck Ring Procurement Guide: What Industrial Buyers Must Know?

Cylinder Neck Ring Procurement Guide: What Industrial Buyers Must Know? Choosing a cylinder neck ring supplier is a critical step in any industrial gas project. Industrial buyers today face a global market, tighter safety regulations, and higher customer expectations. Failure to specify the correct material, overlook corrosion resistance, or skip certification steps can lead to […]

The Role of Cylinder Neck Rings in Safety: Advanced Valve Protection Solutions?

The Role of Cylinder Neck Rings in Safety: Advanced Valve Protection Solutions? Neglecting the cylinder neck ring is one of the leading causes of gas cylinder accidents and expensive recalls. While many focus on cylinder shells or valves, a weak neck ring makes the valve and cap system highly vulnerable to impacts, corrosion, and leaks—leading […]

How to Select the Right High-Pressure Neck Ring: Specifications and Industry Standards?

How to Select the Right High-Pressure Neck Ring: Specifications and Industry Standards? Choosing the right high-pressure cylinder neck ring isn’t just about dimensions—it’s about global safety, lifetime reliability, and legal compliance. For OEMs and procurement teams, a single specification error can lead to gas leaks, regulatory failures, or customer returns. That’s why world-class gas system […]

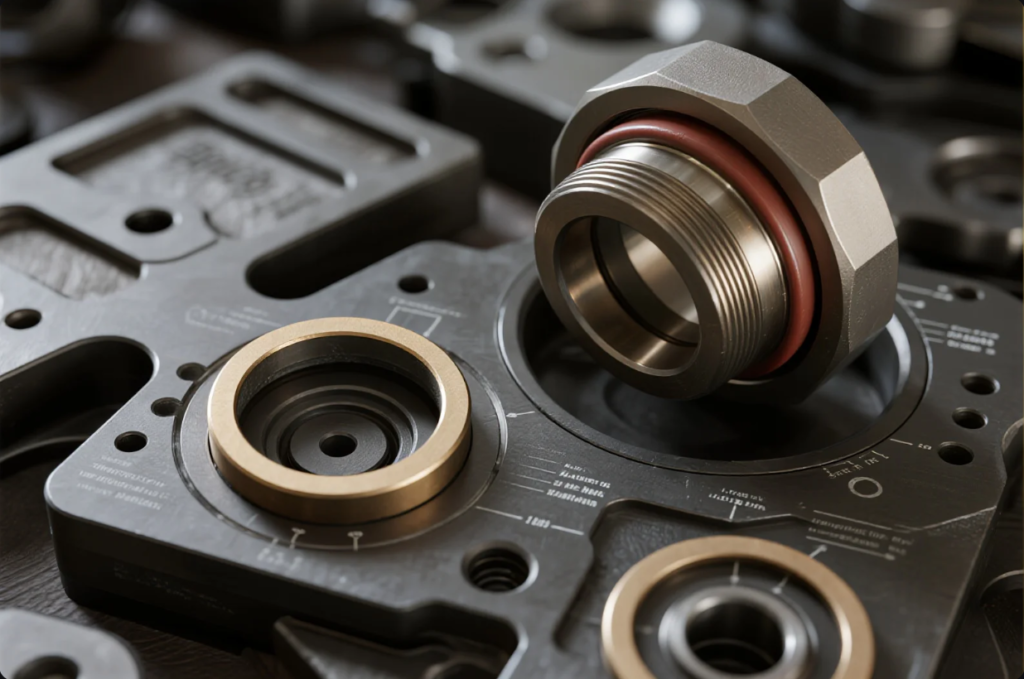

The Complete Manufacturing Process of Cylinder Neck Rings: From Design to Mass Production?

The Complete Manufacturing Process of Cylinder Neck Rings: From Design to Mass Production? Cylinder neck rings are the unsung heroes of industrial gas cylinder safety. They look simple, but a flawless neck ring is the result of dozens of technical steps—each designed to guarantee the highest levels of safety, fit, and global compliance. When procurement […]

Understanding Metal Cylinder Neck Rings: Why Are They Essential for High-Pressure Cylinders?

Understanding Metal Cylinder Neck Rings: Why Are They Essential for High-Pressure Cylinders? Gas cylinder buyers face a complex challenge: they must ensure high-pressure vessels remain safe, leak-free, and compliant with international regulations, all while minimizing cost and downtime. Too often, small overlooked components—like cylinder neck rings—cause large, costly failures that ripple through production and supply […]

How to Choose a Reliable Metal Cylinder Components Manufacturer: Key Criteria for B2B Buyers?

How to Choose a Reliable Metal Cylinder Components Manufacturer: Key Criteria for B2B Buyers? Buyers often risk late deliveries, unstable quality, or poor service by choosing the wrong metal cylinder components supplier. This guide helps B2B buyers screen Chinese manufacturers for quality, customization, delivery, and real-world success. Get practical questions and proven criteria for confident […]

The Ultimate Guide to Custom Metal Cylinder Components: Manufacturing, Applications, and Quality Control?

The Ultimate Guide to Custom Metal Cylinder Components: Manufacturing, Applications, and Quality Control? Manufacturers often face headaches with inconsistent quality, late deliveries, and poor communication when sourcing custom metal cylinder components. This guide breaks down cylinder types, materials, quality standards, and common defects. Get expert insights and actionable tips. Optimize sourcing for stable quality, fast […]