How to Get Custom Precision Plastic Parts Manufactured Efficiently?

How to Get Custom Precision Plastic Parts Manufactured Efficiently? Custom plastic sourcing is often confusing due to design issues or miscommunication. Custom plastic parts1 require the right design, correct material, and optimal process. Clear planning prevents quality issues2 and costly delays. Getting the right plastic part1 involves many steps — design, material choice, production, and […]

What is the easiest plastic to injection mold?

What is the easiest plastic to injection mold? Injection molding is a widely used manufacturing process for producing plastic parts. Many designers and engineers want to know which plastic material1 is easiest to work with in this process. The answer could save you time, money, and headaches in your production cycles. Polypropylene (PP)1 is generally […]

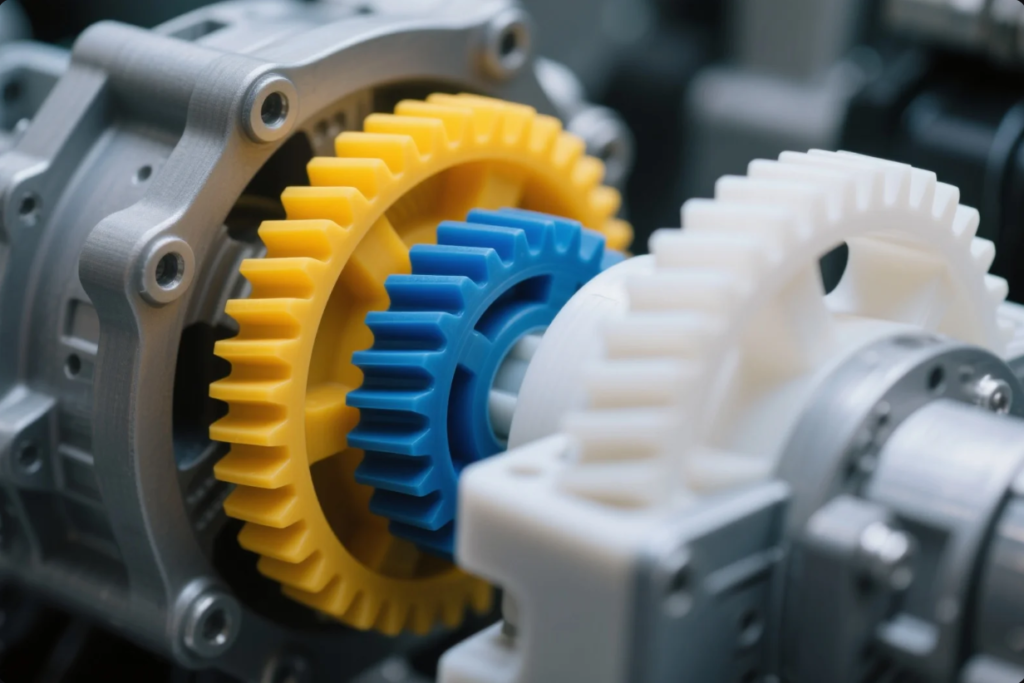

Plastic vs. Metal Parts: When to Choose Plastic?

Plastic vs. Metal Parts: When to Choose Plastic? Many engineers and buyers struggle to decide between plastic and metal parts. Making the wrong choice can result in product failure or excess cost. Plastic and metal parts each offer unique advantages. The best choice depends on your project’s application, strength requirements, cost targets, and environmental demands. […]

How to Choose the Right Plastic Material for Your Custom Parts?

How to Choose the Right Plastic Material for Your Custom Parts? Introduction Are you struggling to pick the best plastic material for your project? You’re not alone. Many buyers find the plastic material selection process complicated. Selecting the right plastic material ensures product reliability, quality, and cost efficiency. Consider use, environment, durability, and processing methods […]

How to Choose the Right Plastic Material for Custom Parts?

Below is the enhanced full English version of the article with **40+ # How to Choose the Right Plastic Material for Custom Parts? Having repeated product failures or post-sale returns? The root cause may be poor material selection. Choosing the right plastic ensures parts perform well under stress, heat, and impact. You must align plastic […]

What are the 10 advantages of plastic?

What Are the 10 Advantages of Plastic? Plastic has become essential in manufacturing—but why do industries rely on it so heavily? Plastic is durable, lightweight, versatile, and cost-effective. It resists corrosion, allows flexible design, and supports mass production. Plastic supports multiple industries. But how exactly does it benefit your production process? Let’s dig into ten […]

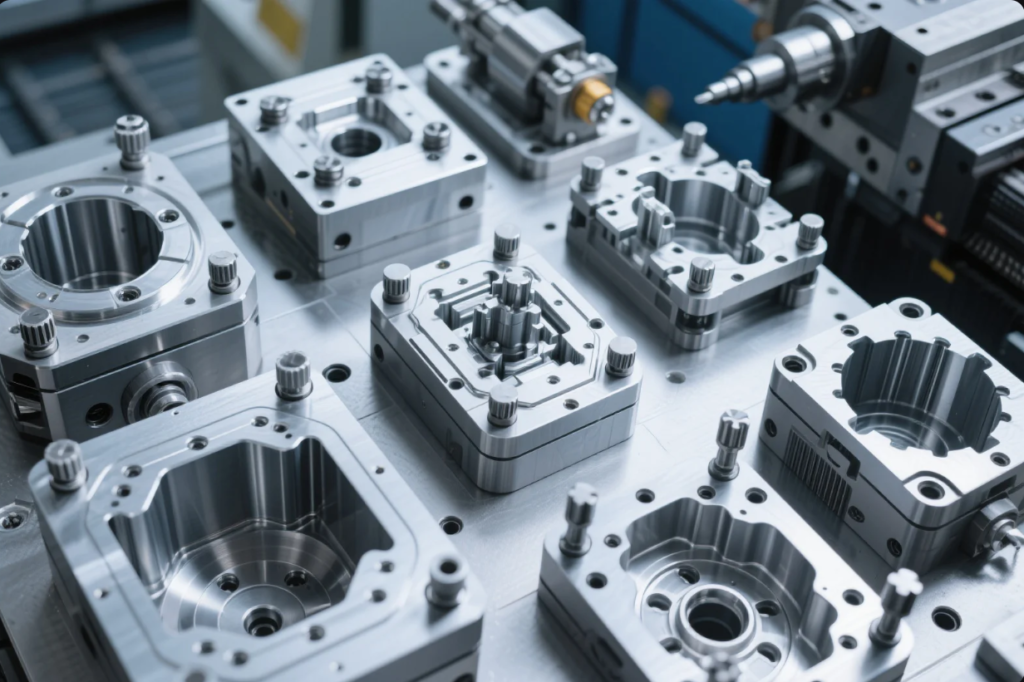

Tolerances and Surface Finishes in Plastic Injection Molding: What Engineers Must Know?

Tolerances and Surface Finishes in Plastic Injection Molding: What Engineers Must Know? Designing injection-molded plastics requires understanding tolerances and finishes—these define functionality, aesthetics, cost, and manufacturability. Knowing standard vs. precision tolerances, SPI surface grades, cosmetic vs. functional finishes, and inspection protocols helps engineers reduce defects and optimize designs. This guide walks through each topic with […]

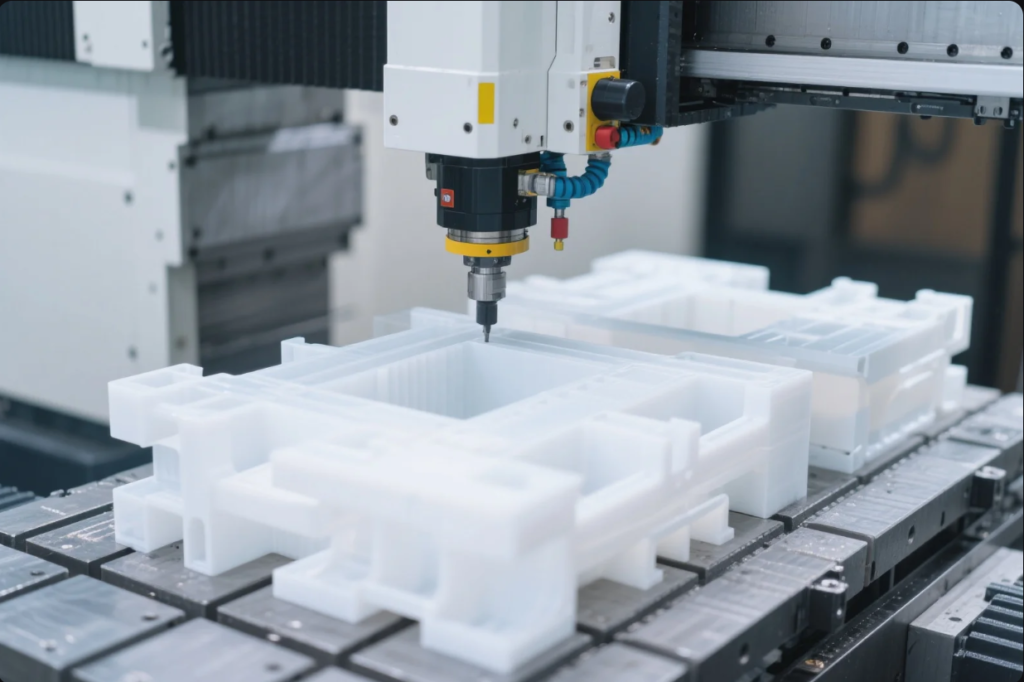

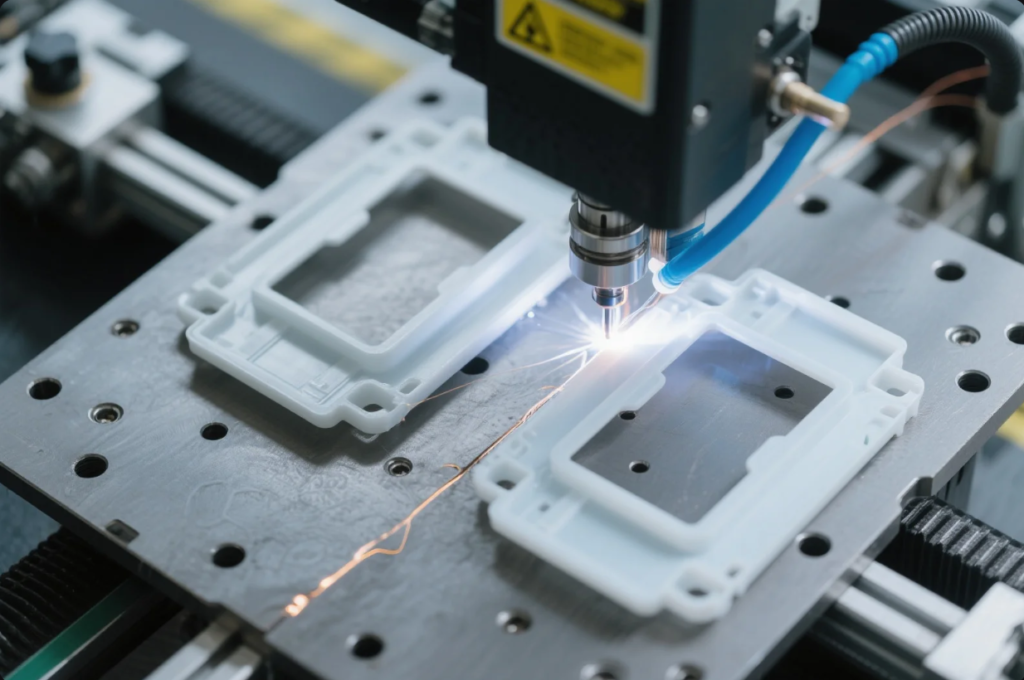

Plastic Prototyping Methods: CNC Machining vs. 3D Printing vs. Soft Mold Tooling?

Plastic Prototyping Methods: CNC Machining vs. 3D Printing vs. Soft Mold Tooling? Selecting the right prototyping method impacts speed, cost, and validation for final production. Choosing between CNC machining, 3D printing, and soft tooling depends on desired precision, material properties, and volume. This guide dives into each method, compares their advantages, and explains how to […]

High‑Performance Engineering Plastics: Nylon, PPS, and PC in Modern Industries?

High‑Performance Engineering Plastics: Nylon, PPS, and PC in Modern Industries? When industries push limits—higher heat, greater stress, chemical exposure—standard plastics like ABS fall short. Engineering plastics such as PC, PA, PPS, and PAEK deliver superior strength, thermal stability, and chemical resistance. This guide compares major resins, explores EV and automotive applications, outlines best practices, and […]

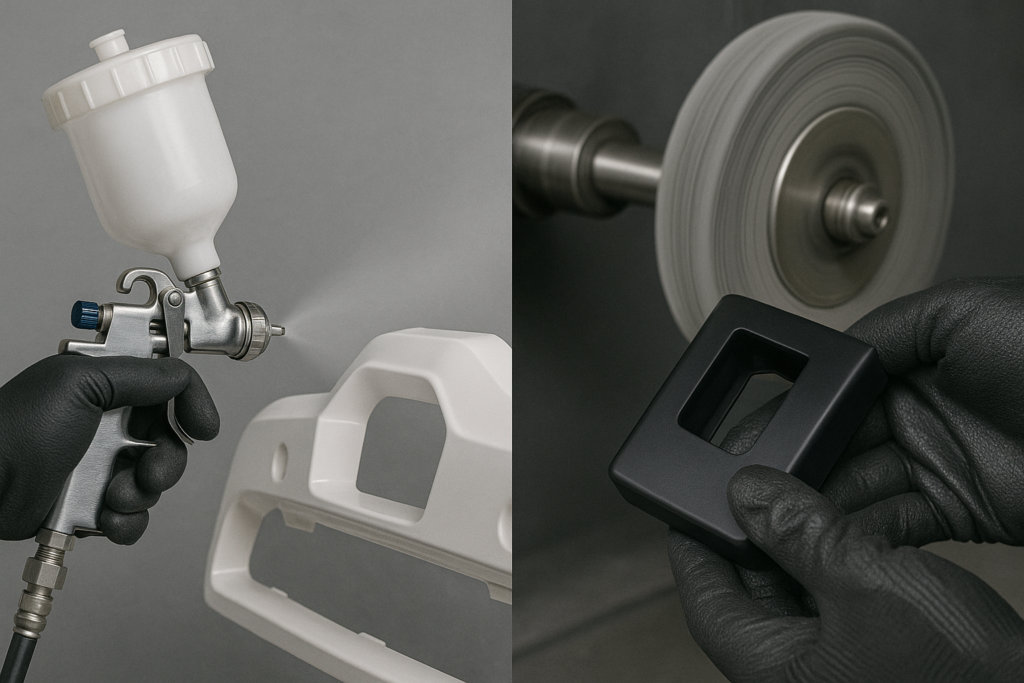

Post-Processing for Injection Molded Parts: Finishing, Welding, and Testing Explained?

Post-Processing for Injection Molded Parts: Finishing, Welding, and Testing Explained? Injection molded parts often need extra steps—welding, surface treatment, testing, and validation—to meet performance, aesthetics, and regulatory requirements. Selecting optimal post-processing ensures functional reliability, brand impact, and market compliance. Let’s explore welding options, finishing techniques, testing protocols, and certification essentials. Ultrasonic welding vs. hot plate […]