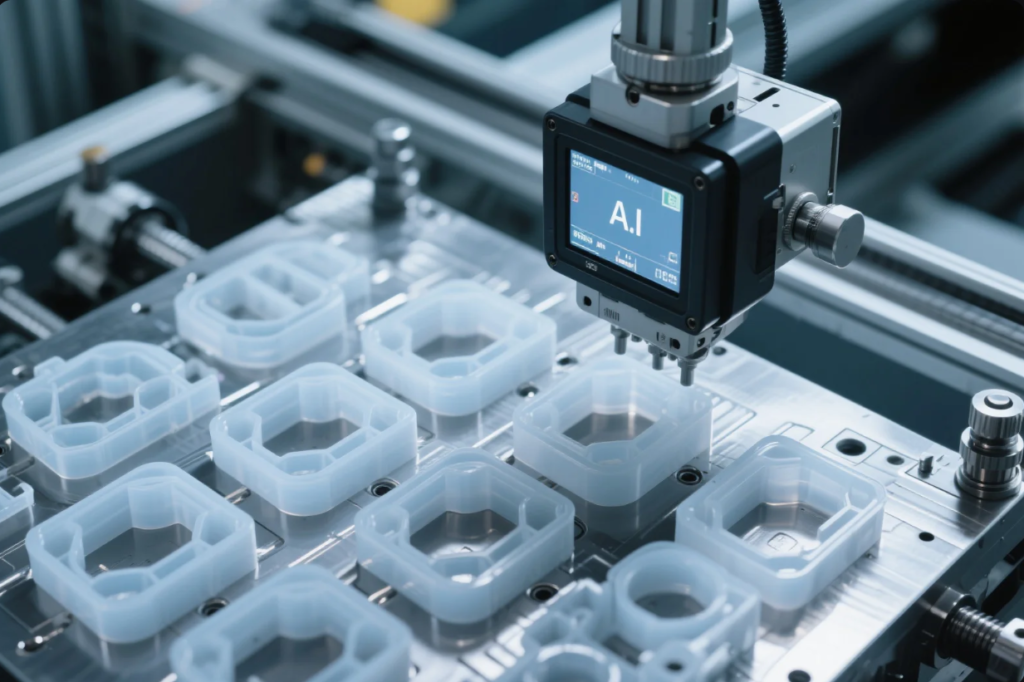

Smart Manufacturing for Plastic Parts: AI, Automation, and Quality Control?

Smart Manufacturing for Plastic Parts: AI, Automation, and Quality Control? In plastic part production, inefficiencies lead to defects, delays, and cost overruns. Smart manufacturing—leveraging IoT, AI, automated tooling, and lights-out operations—brings consistency, speed, and traceability to injection molding. Implementation delivers real-time quality control, optimized processes, and scalable output. Industry 4.0: IoT, OPC-UA, and MES redefine production […]

Sustainable Plastic Components: Biodegradable Materials and Circular Solutions?

Sustainable Plastic Components: Biodegradable Materials and Circular Solutions? I’ve heard claims about green plastics. I felt lost in jargon and supplier buzzwords. Biodegradable materials like PLA, PHA, PBS, and PBAT—coupled with mechanical, chemical, and enzymatic recycling strategies—enable a circular, compliant, and cost-effective value chain. This deep-dive guide covers material science, regulations, certifications, recycling methods, and […]

How to Choose the Right Injection Molded Plastic Parts Manufacturer?

How to Choose the Right Injection Molded Plastic Parts Manufacturer? I’ve struggled with unreliable plastic parts suppliers before. Injection molded plastic parts require precision, speed, and quality. Choosing the right supplier ensures your project succeeds. I used to experience frequent delays and defective products due to poor supplier selection. These issues disrupted production, hurt customer […]

Plastic Material Selection for High-Performance OEM Components

Plastic Material Selection for High-Performance OEM Components Introduction Selecting the right plastic for OEM parts is critical to balancing performance, cost, regulatory compliance, and manufacturability. High-performance thermoplastics such as PEEK, PPS, PA66, and PC are revolutionizing industries like aerospace, medical, automotive, and electronics. This guide helps engineers and procurement professionals evaluate and select the best […]

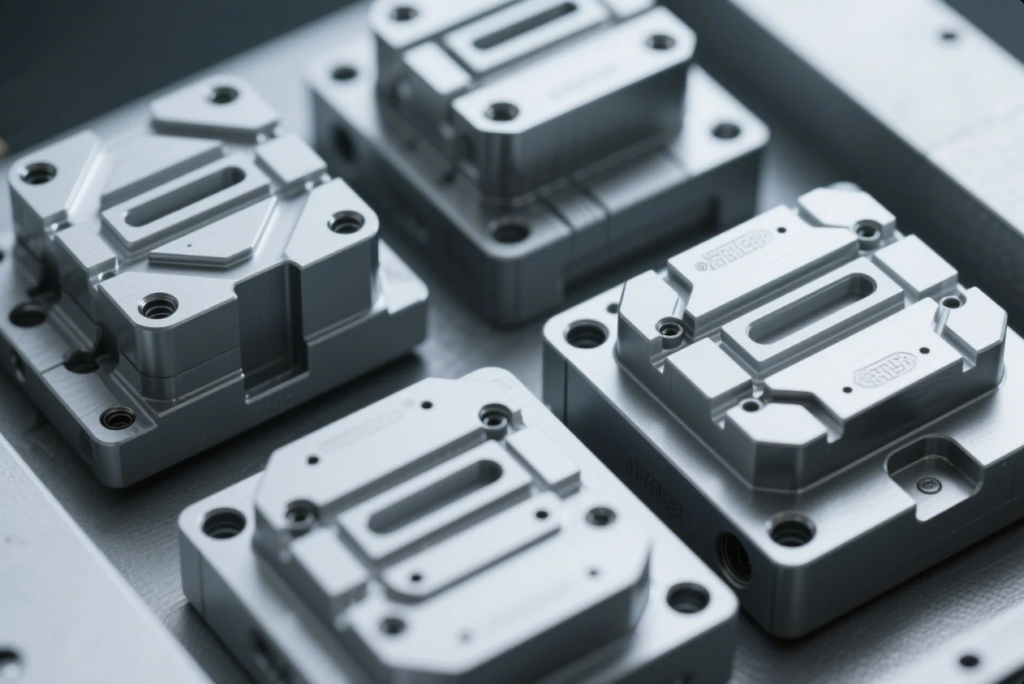

OEM Plastic Part Production: From DFM to Mass Production

OEM Plastic Part Production: From DFM to Mass Production Introduction Bringing an OEM plastic part to life involves far more than injection molding. It begins with design for manufacturability (DFM), flows through prototyping, tooling validation, and concludes with packaged, globally shipped final parts. This guide walks you through every stage of production — from early […]

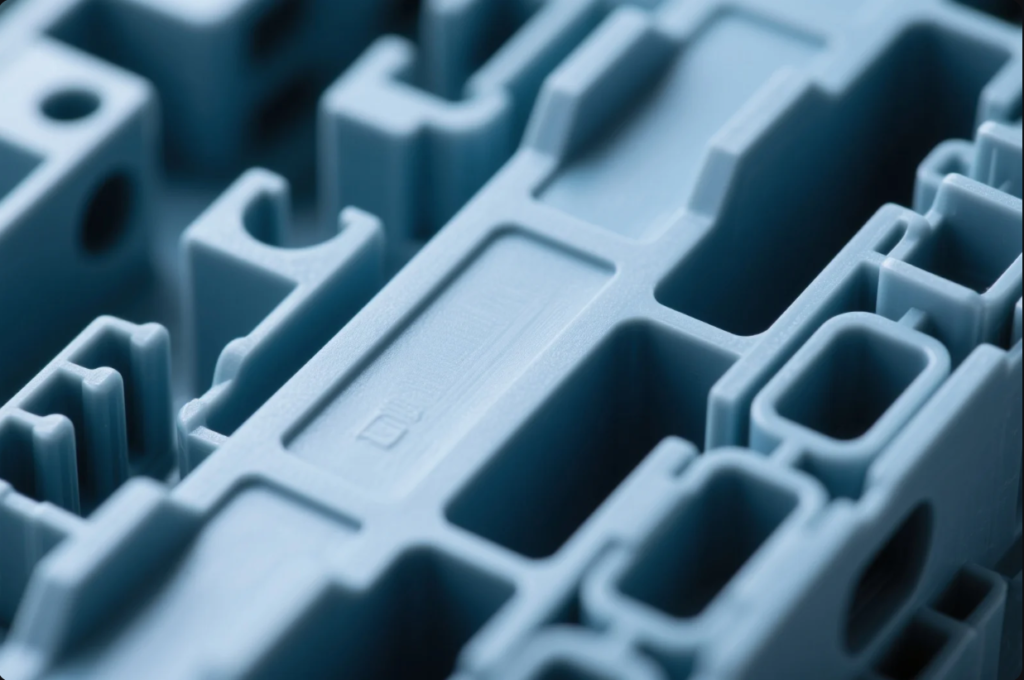

Injection Molding Tolerances & Surface Finishes Demystified

Injection Molding Tolerances & Surface Finishes Demystified Introduction Injection molding is the preferred process for high-volume plastic part production — but achieving high-quality outcomes requires tight dimensional control and attention to surface finish. This article demystifies the key tolerancing standards and surface classifications used in the industry. Whether you’re designing parts for automotive, medical, or […]

Top Plastic Materials for OEM Applications: ABS, PC, PEEK & More

Top Plastic Materials for OEM Applications: ABS, PC, PEEK & More In OEM manufacturing, material selection directly affects product success. From low-cost parts to aerospace-grade components, the right thermoplastic can improve performance, cut costs, and simplify design. This article introduces ABS, PC, PEEK, and more — with practical insights for engineers, buyers, and designers. Introduction […]

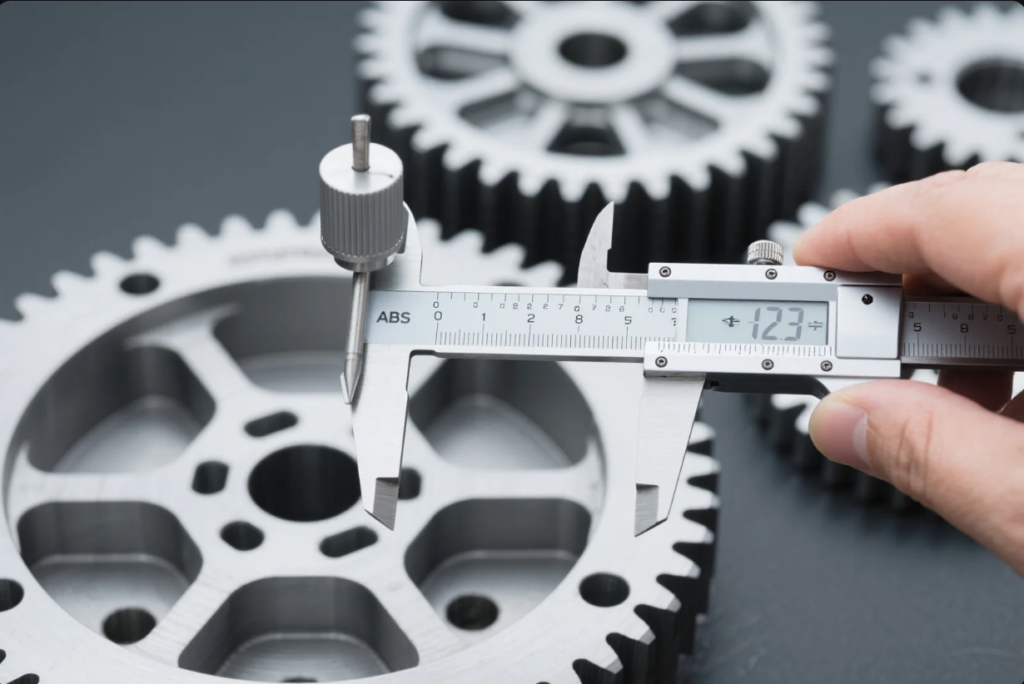

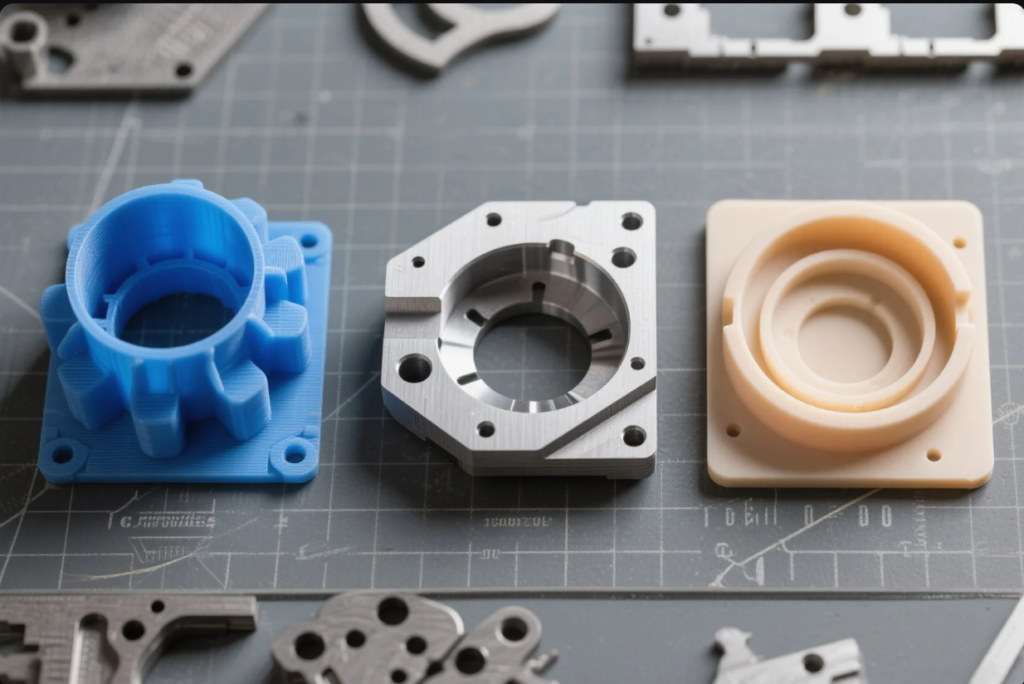

CNC vs Injection Molding: Best Methods for Plastic Parts

CNC vs Injection Molding: Best Methods for Plastic Parts Choosing between CNC machining and injection molding is a key decision in plastic part production. This in-depth guide compares both methods based on cost, lead time, accuracy, and application to help engineers, procurement professionals, and OEMs choose the right strategy for their plastic projects. Introduction Plastic […]

OEM Plastic Part Manufacturing: From Design Assistance to Mass Production

OEM Plastic Part Manufacturing: From Design Assistance to Mass Production Supplying plastic parts to OEMs requires more than injection molding alone. You need expertise in design, prototyping, tooling, quality control, and global logistics. PrimeCustomParts.com delivers that end-to-end solution. This guide explains every step and decision point, with actionable design tips, prototyping options, quality standards, and […]

CNC Machined Plastic Parts vs Molded Parts: Which Is Right for You?

CNC Machined Plastic Parts vs Molded Parts: Which Is Right for You? Choosing between CNC machining and injection molding is a critical decision for plastic part production. Each method offers strengths and limitations in terms of cost, lead time, precision, surface finish, and production volume. In this comprehensive guide, we’ll explore the key differences to […]