Stamping Die Maintenance: Ensuring Precision in Every Part

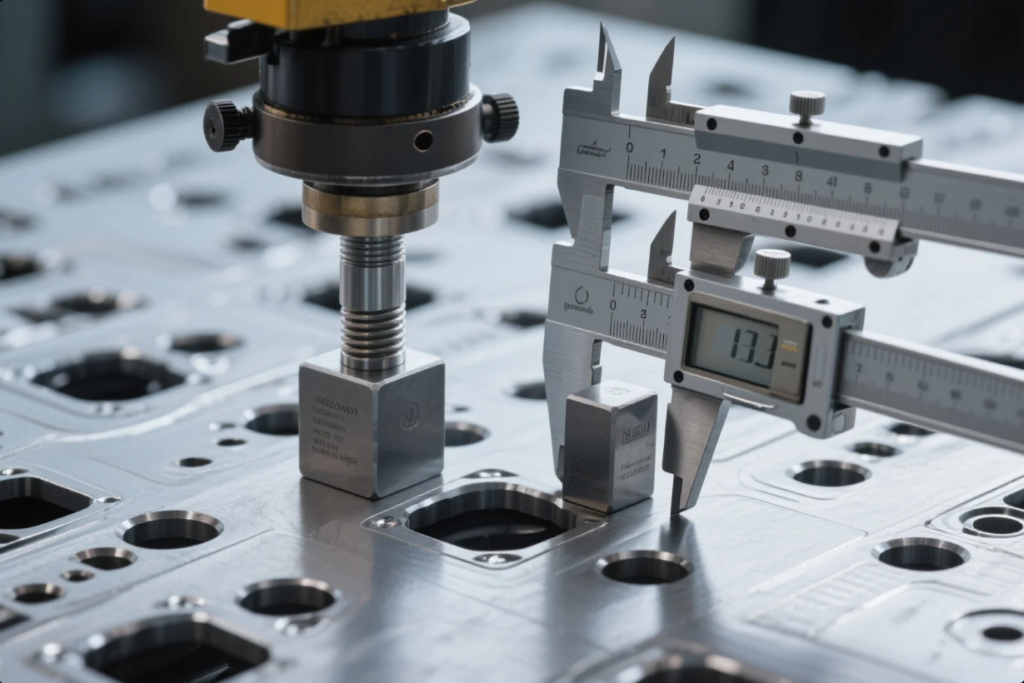

Stamping Die Maintenance: Ensuring Precision in Every Part How stamping tolerance affects die accuracy Stamping to a tolerance of ±0.02 mm is essential for ISO 2768 and automotive standards such as IATF 16949. Small deviations from die wear or press misalignment can cause part rejection, assembly issues, and increased scrap costs, as documented by MetalForming Magazine […]

Progressive Die Design: Boosting Efficiency in Metal Stamping?

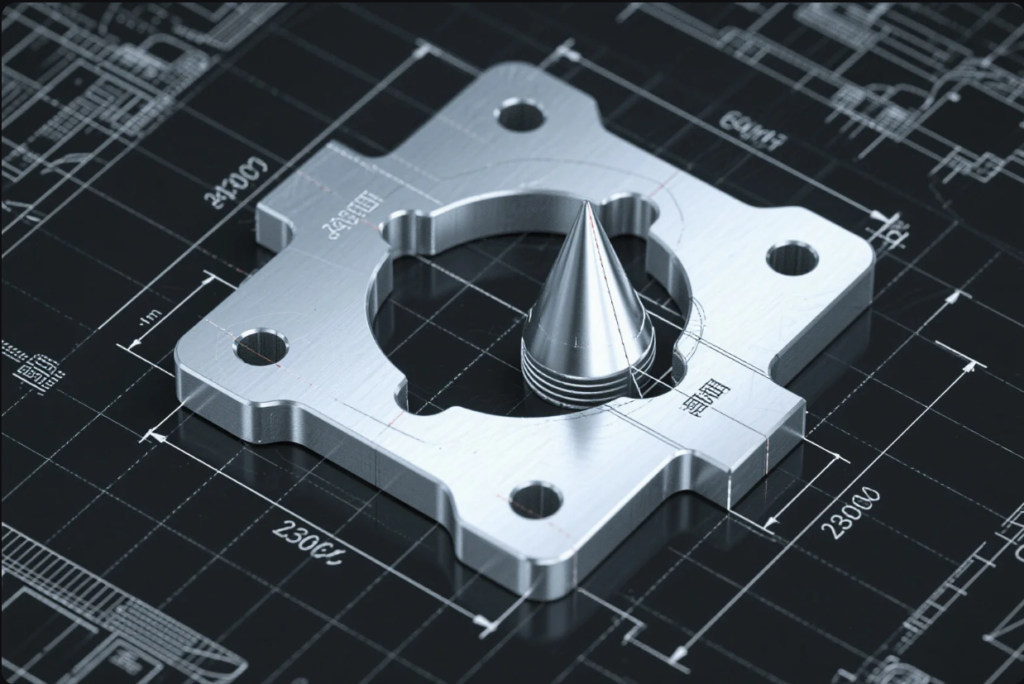

Progressive Die Design: Boosting Efficiency in Metal Stamping? What is a progressive die? Step-by-step process explained A progressive die performs multiple operations along a strip of metal in one stroke. Each station forms, punches, bends, or trims. This results in near-finished parts at the end of the strip—ideal for high-volume efficiency. This differs from B‑punch […]

Deep Drawing in Metal Stamping: Die Design and Applications?

Deep Drawing in Metal Stamping: Die Design and Applications? What is deep drawing and how does it differ from standard stamping? Deep drawing uses punches and dies to stretch sheet metal into 3D hollow shapes, unlike standard stamping that cuts or forms flat profiles. This process is widely used in automotive manufacturing, consumer appliances, medical […]

How to Choose the Right Metal Stamping Die for Precision Parts?

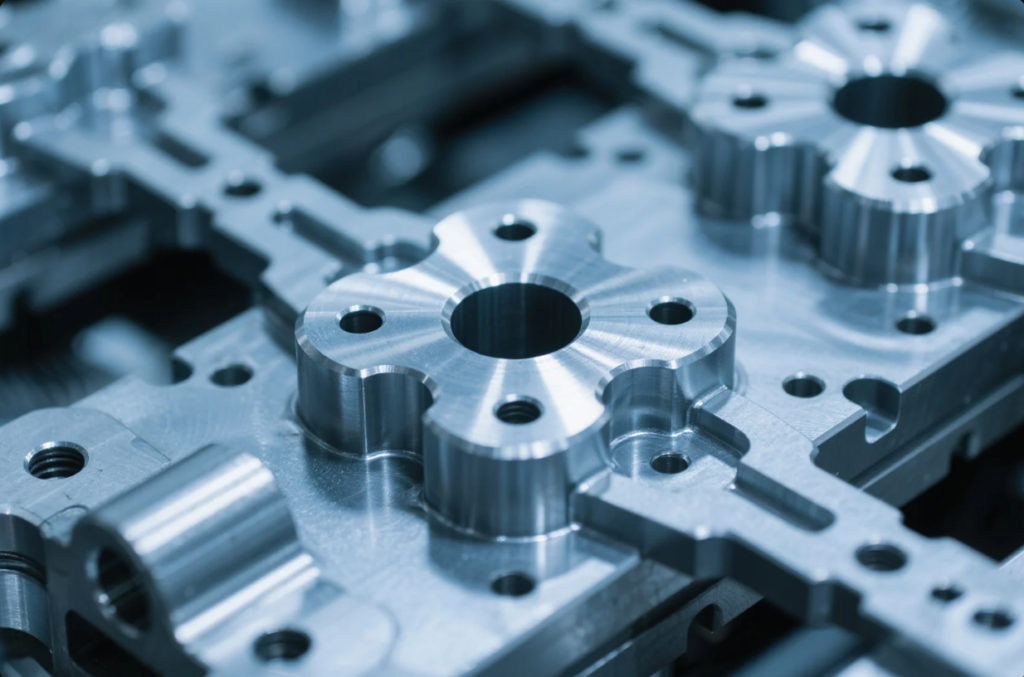

How to Choose the Right Metal Stamping Die for Precision Parts? Why Choosing the Right Die Matters I faced poor part quality and late shipments before. It all traced back to the wrong die choice. Once I learned how to evaluate stamping dies, my quality and delivery improved fast. Summary: Choosing the right stamping die […]

Top 5 Applications of Metal Stamping Parts Across Industries

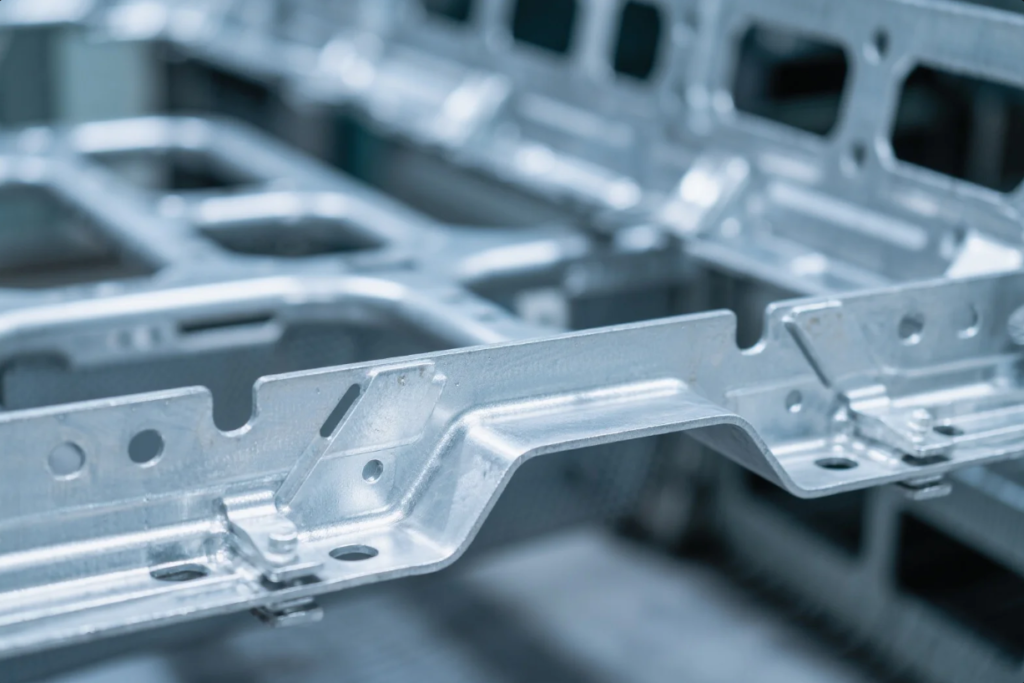

Top 5 Applications of Metal Stamping Parts Across Industries Automotive Applications Metal stamping plays a critical role in the automotive industry. Components like brackets, chassis parts, and fuel tank elements rely heavily on precision stamping methods. Brackets & Supports These components mount engines, transmissions, seats, and more. They must comply with IATF 16949 standards for […]

How to Meet Tight Tolerances in Precision Metal Stampings

How to Meet Tight Tolerances in Precision Metal Stampings Tolerance Levels: ±0.05 mm vs. ±0.01 mm 60% of metal stamping buyers consider tolerance the single most important spec. Let’s define levels: ±0.05 mm fits general applications like enclosures or brackets. ±0.01 mm suits surgical, aerospace, or microelectronic components. Achieving these ranges demands control across every manufacturing step. References: ASME […]

Progressive Die vs. Deep Draw Stamping: What’s Best for Your Project?

Progressive Die vs. Deep Draw Stamping: What’s Best for Your Project? Process Overview: Progressive Die Stamping Explained Progressive die stamping produces flat, precise parts at high speed. A metal coil moves through a die with multiple stations, with each performing a stage of the forming process. The result is a fully formed part automatically ejected […]

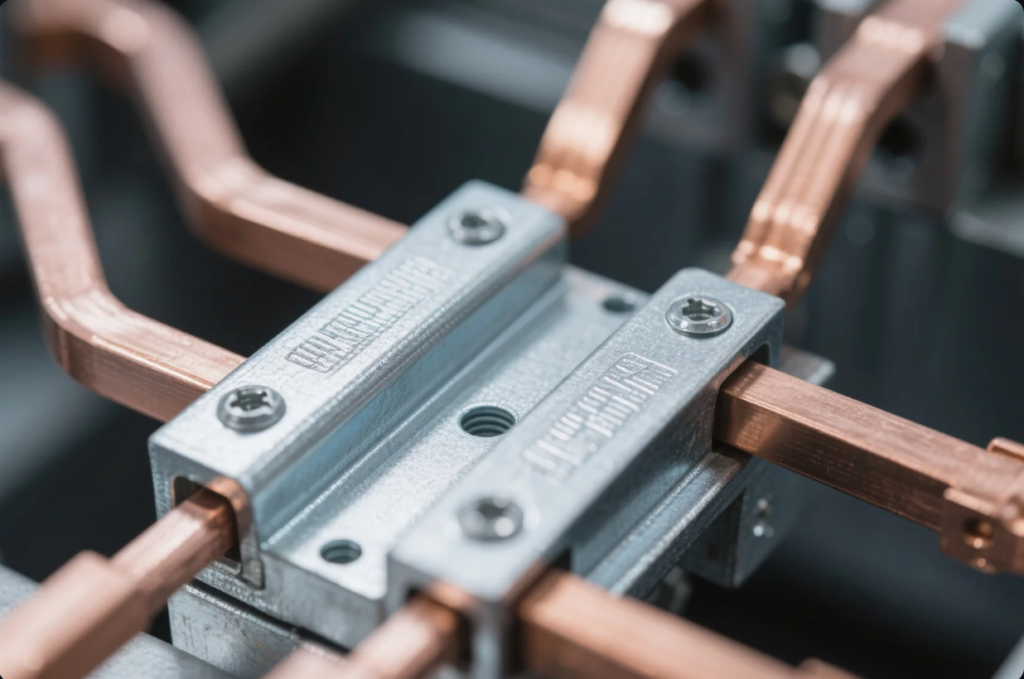

Choosing the Right Material for Metal Stamping Parts: Stainless Steel to Carbon Steel

Choosing the Right Material for Metal Stamping Parts: Stainless Steel to Carbon Steel Introduction: Why Material Choice Matters Choosing the right metal stamping material impacts cost, strength, and performance. The wrong alloy can cause failures, delays, or high rework costs. Smart buyers look beyond price—they consider corrosion resistance, conductivity, weight, and machinability. That’s how you protect margins […]

High‑Volume Precision Metal Stamping Parts: Key Factors for Success

High‑Volume Precision Metal Stamping Parts: Key Factors for Success Introduction: Why Precision Stamping Fails at High Volume Stamping is not just pressing metal—it’s engineering at scale. Without precision, high-volume projects fail. Industries like automotive and consumer electronics require repeatable tolerances down to ±0.05 mm. A small deviation can ruin assemblies, cause warranty issues, or trigger recalls. […]

Best Materials for High-Performance Metal Stamping Parts in 2025

Best Materials for High-Performance Metal Stamping Parts in 2025? I often face stamping failures caused by wrong material choices. I need clear guidance now. This guide compares stainless steel, aluminum, copper, and brass for stamped parts. It reviews strength, ductility, cost, and tooling impacts. Each material’s pros, cons, and use cases are presented clearly. Keep […]