Top Cost Factors of Custom Welding Parts Manufacturing: A Practical Guide?

Top Cost Factors of Custom Welding Parts Manufacturing: A Practical Guide? I watch buyers guess welding prices[^1]. They look at part size, not weld volume[^2]. That guess kills margins and trust. Welding cost comes from weld volume[^1], deposition rate[^2], and time. I multiply weld length by 0.707×a² for fillet volume, convert volume to filler mass […]

How to Reduce Costs in Custom Metal Welding Parts: Top Proven Strategies?

How to Reduce Costs in Custom Metal Welding Parts: Top Proven Strategies? Costs keep climbing1, and schedules slip2. I face this often. I fix both with clear, simple steps. You can cut welding costs1 by aligning materials, design, processes, and logistics. Choose fit-for-purpose metals2 and consumables. Simplify joints and fixtures. Match MIG, TIG, or robots […]

How should buyers choose wire welders and welding wire for custom welding parts?

Delays, rework, and scrap often come from mismatched machines1, wires, and gases. Choose the welding process1 (GMAW/MIG, FCAW-G, FCAW-S, or pulsed MIG) based on environment and thickness; then select a wire classification2 (e.g., ER70S-6, E71T-1C/M, ER308L, ER4043/5356), diameter (0.8–1.2 mm / 0.030–0.045"), shielding gas (e.g., C25), and correct polarity. Verify WPS/WPQR and inspection before production. […]

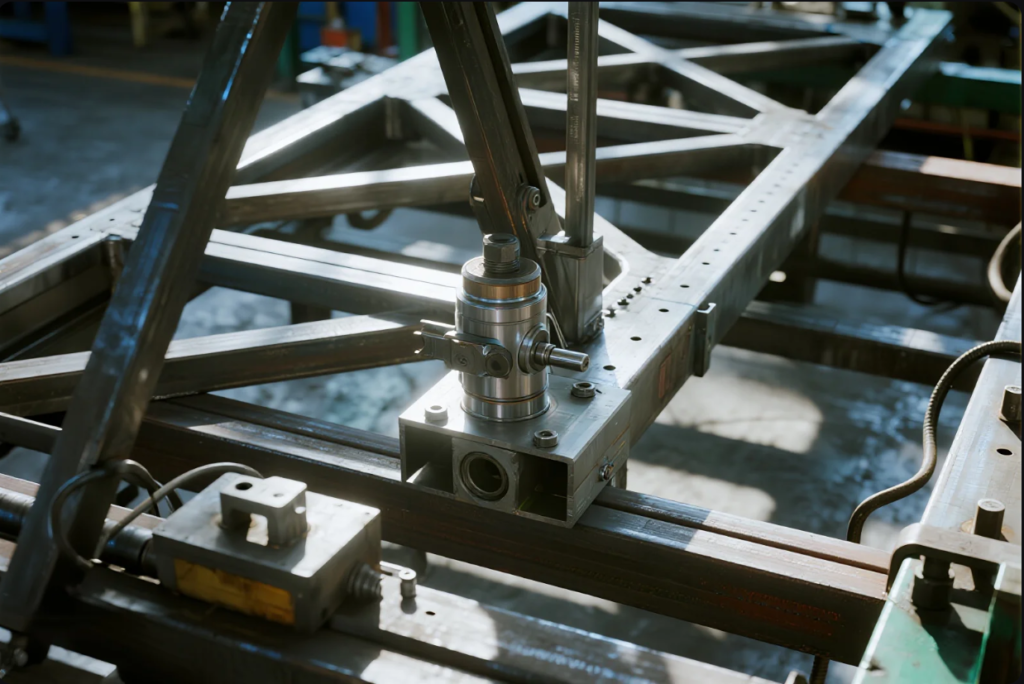

How to Choose a Custom Welding Parts Manufacturer for Your Industrial Project?

How to Choose a Custom Welding Parts Manufacturer for Your Industrial Project? Welding parts failing during use? That’s not just costly—it’s dangerous. Choosing the right welding parts manufacturer1 ensures safety, quality, and delivery reliability. Evaluate process types, certifications2, and logistics efficiency before committing. Poor welding quality or late shipments can lead to lost revenue and […]

Understanding Welding Defects, Surface Treatments, and Best Practices for High-Performance Metal Parts?

Understanding Welding Defects, Surface Treatments, and Best Practices for High-Performance Metal Parts? Hidden weld defects, rapid corrosion, and unpredictable joint failures are common headaches for buyers and engineers sourcing metal parts worldwide. These challenges cost time, cause safety risks, and hurt reputations. To deliver high-performance, long-life results, you must understand welding defects, select the right […]

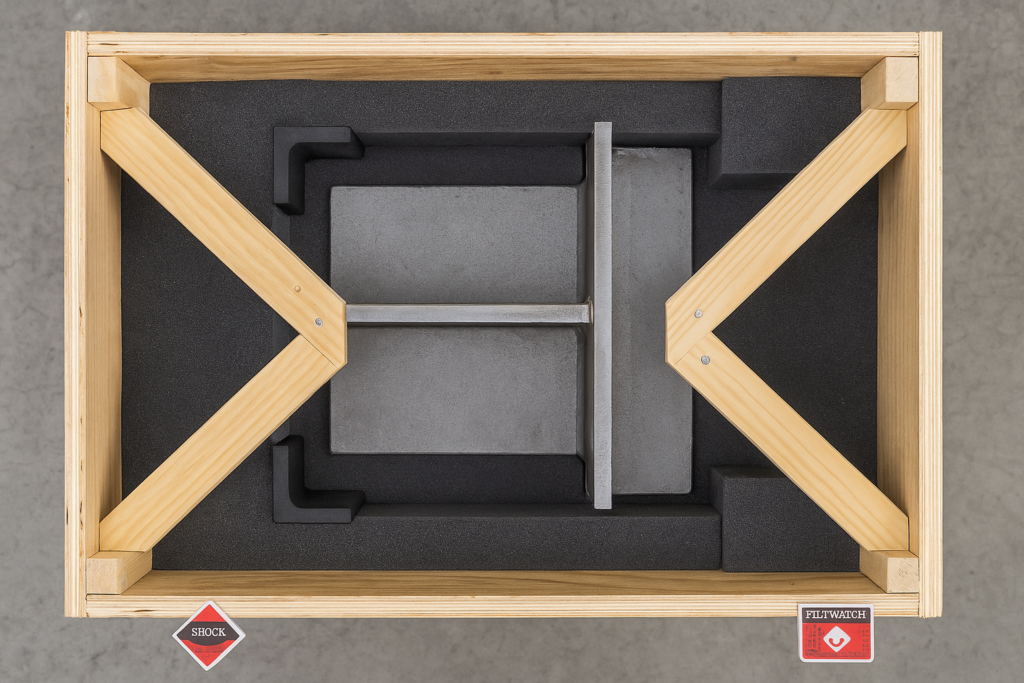

How to Source Custom Welded Metal Parts from China: Supplier Selection, Process Control, and Quality Assurance?

How to Source Custom Welded Metal Parts from China: Supplier Selection, Process Control, and Quality Assurance? Many buyers struggle with delayed shipments, vague specifications, or inconsistent quality when sourcing custom welded metal parts from China. These issues can create real business risk, especially for projects with tight schedules or strict standards. To succeed, buyers must […]

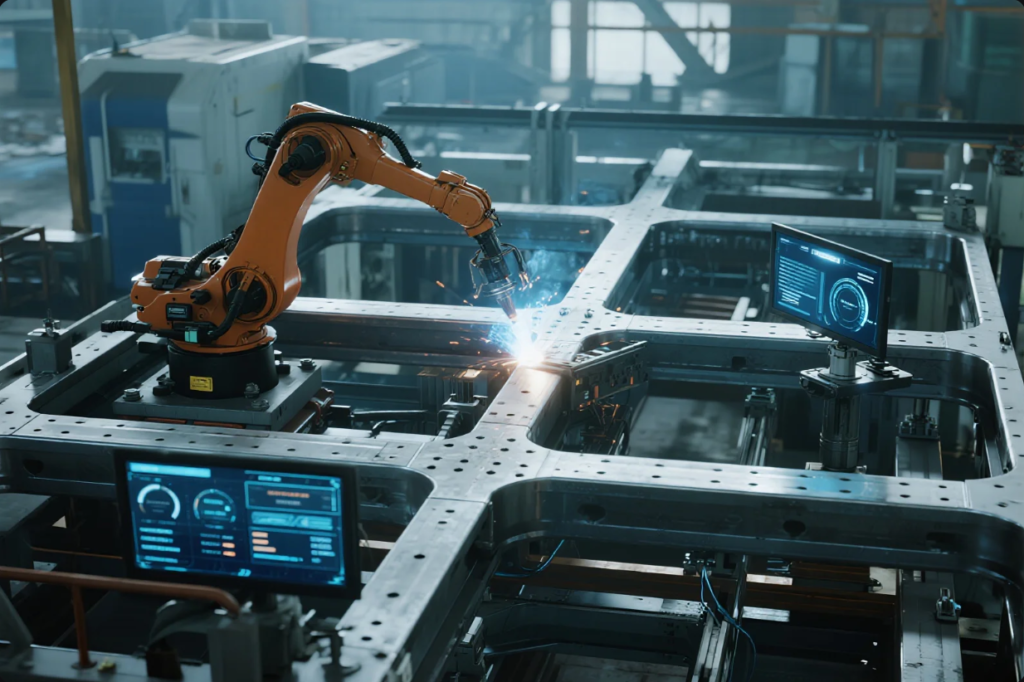

A Complete Guide to Metal Welding Parts: Types, Techniques, and Industrial Applications?

A Complete Guide to Metal Welding Parts: Types, Techniques, and Industrial Applications? Many industrial buyers feel lost when sourcing metal welding parts. They struggle with inconsistent quality, unreliable delivery, and a lack of technical support from suppliers. Understanding the types of metal welding parts, comparing major welding techniques, and knowing the essential quality certifications help […]

What Do Welding Rod Numbers Mean?

What Do Welding Rod Numbers Mean? You often face welding defects. You might pick the wrong rod. We help you avoid that. Welding rod numbers show strength, position, and coating. Learn the codes to boost weld quality and match jobs. Many buyers lose time and money due to rod confusion. This guide explains the numbers […]

The Importance of Weld Purging for Alloy Parts

The Importance of Weld Purging for Alloy Parts Weld oxidation ruins critical alloy parts. Discoloration, weak joints, or corrosion can follow if purging is neglected. You need controlled purging to ensure joint integrity. Weld purging—clearing oxygen from inside joints—is essential for alloys like stainless and titanium. Choosing the right gas (argon vs helium), following setup […]

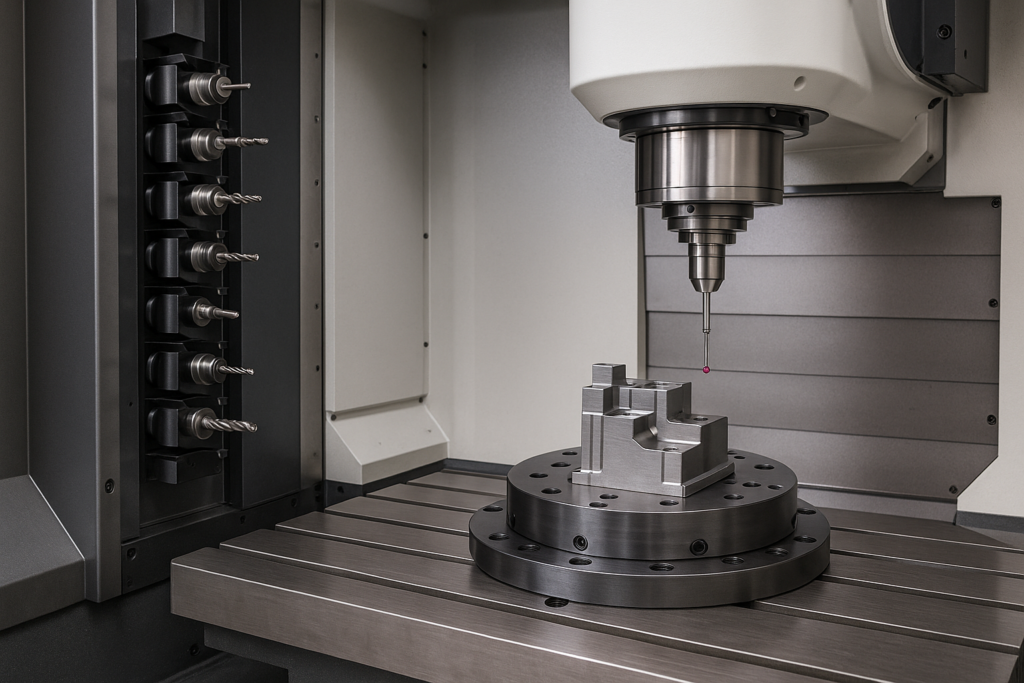

Welding Inspection & Quality Assurance Explained

Welding Inspection & Quality Assurance Explained Manufacturers often miss welding issues until it’s too late. Quality lapses cause costly delays. You need thorough QA to build trust and reduce risk. Weld inspection should cover every stage—from pre-weld checks to in-process monitoring and final evaluation. Applying MPI, PT, radiography, and digital vision systems ensures defect-free outcomes. […]