Top 7 Companies Providing Custom Steel Welding Parts Worldwide

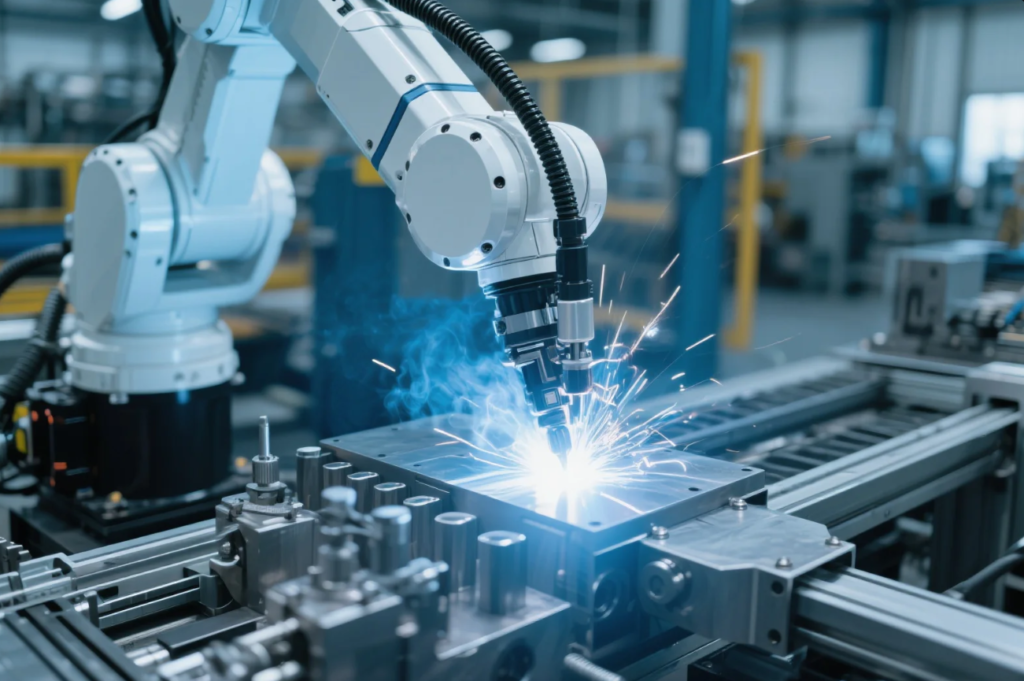

Top 7 Companies Providing Custom Steel Welding Parts Worldwide Steel welding parts power the backbone of global industry—from heavy machinery and infrastructure to energy and transportation. In 2025, choosing a reliable custom steel welding supplier is not about cost alone—it’s about capacity, quality, lead time, and global logistics. This comprehensive guide introduces 7 of the […]

Top-Rated Custom Welding Suppliers in China: Capacity, Price & Quality

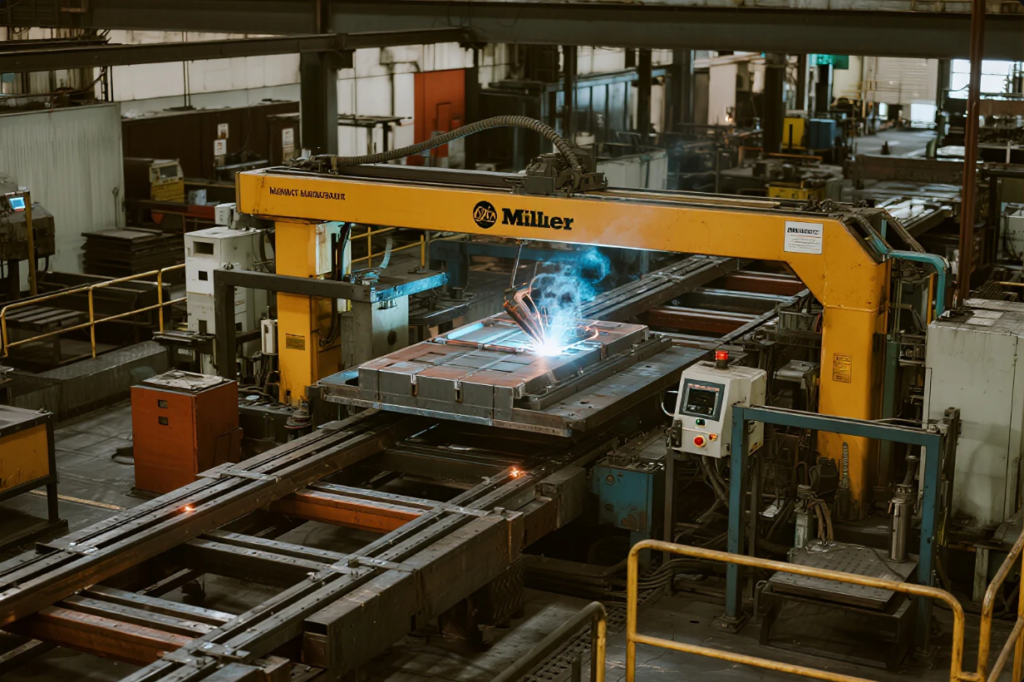

Top-Rated Custom Welding Suppliers in China: Capacity, Price & Quality Sourcing custom welding parts from China can be a game-changer—or a costly mistake. In 2025, China’s best welding suppliers offer more than low cost—they deliver global quality, production flexibility, and expert technical support. This article explains how to identify the best Chinese welders, what to […]

Top Global Welding Fabrication Companies for Custom Metal Assemblies

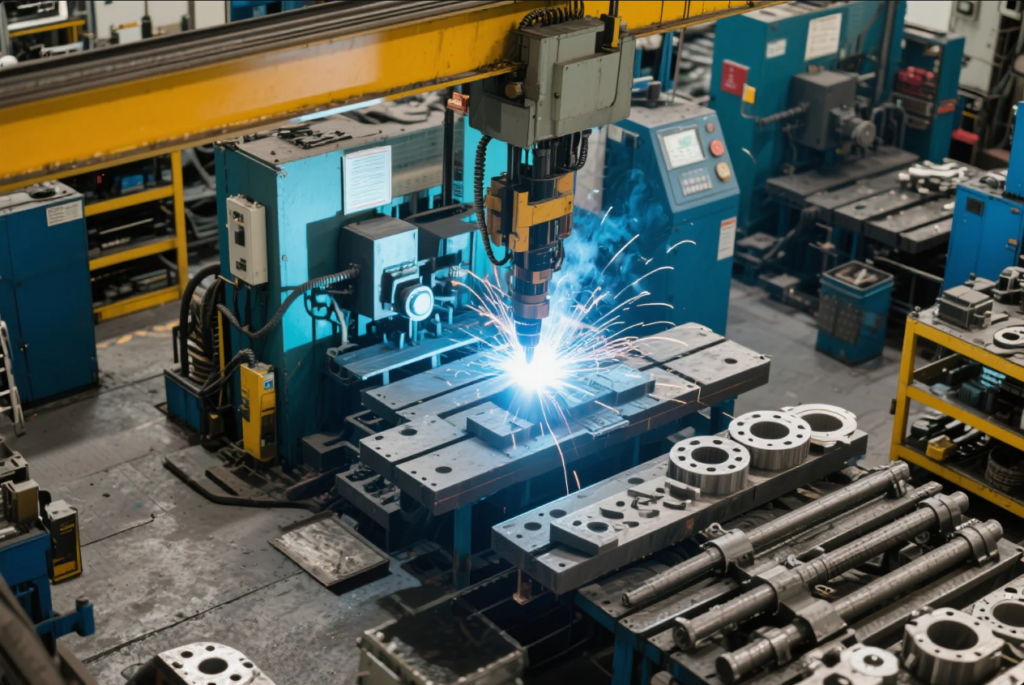

Top Global Welding Fabrication Companies for Custom Metal Assemblies Industrial projects often face delays, weak welds, and inconsistent communication. These issues disrupt schedules and budgets. Leading welding fabrication companies in 2025 offer ISO‑certified assemblies, automated welding, and export‑ready delivery worldwide. This guide dives deep into key players, cost factors, selection criteria, and real‑world tips to […]

Top 10 Custom Welding Parts Manufacturers for Industrial Projects in 2025

Top 10 Custom Welding Parts Manufacturers for Industrial Projects in 2025? Late deliveries. Poor weld strength. Misaligned joints. These issues ruin industrial projects. Top welding parts manufacturers in 2025 offer certified quality, precise joints, and fast, export-ready service. Keep reading to discover which suppliers lead this year and how to pick the best welding parts […]

Top 10 Welding parts manufacturers in 2025

Top 10 Welding Parts Manufacturers in 2025: Capabilities, Expertise, and Selection Criteria? Choosing the right welding parts manufacturer is crucial for ensuring product quality, meeting delivery schedules, and maintaining competitive pricing. In 2025, the welding industry continues to evolve with advancements in automation, precision engineering, and global supply chain integration. Selecting a manufacturer with proven […]

Top Welding Components of 2025: Enhancing Safety and Efficiency in Welding Operations

Top Welding Components of 2025: Enhancing Safety and Efficiency in Welding Operations In the rapidly evolving landscape of industrial manufacturing, welding remains a cornerstone process that demands both precision and safety. As we navigate through 2025, technological advancements have revolutionized welding equipment, introducing components that not only enhance operator safety but significantly boost operational efficiency. […]

What’s the hardest thing to weld?

What’s the Hardest Thing to Weld? Introduction: Why Welding Quality Is the Key If you buy industrial components, you know poor welding quality leads to costly rework, missed deadlines, or even failed projects. I have faced issues with suppliers unable to handle demanding welding jobs, especially with metals like titanium and cast iron. Many global […]

How to write an application for welding?

How to Write an Application for Welding? Writing a welding application? Here’s how to stand out and get hired fast. A welding application must highlight technical skills, certifications, and hands-on experience. Tailor it to match the job description. Whether you’re applying for a welding job or requesting welding services, a clear and structured application makes […]

What are the applications of welding?

What Are the Applications of Welding? Introduction: Why Welding Applications Matter in Modern Industry In today’s industrial world, welding shapes every aspect of infrastructure and product design. If you walk into a major factory, you’ll see welding robots, manual stations, and inspection labs—each essential for modern production. Reliable welding underpins the construction of bridges, power […]

What brand of welders are made in the USA?

What Brand of Welders Are Made in the USA? Introduction: Why "Made in the USA" Matters Choosing a welder that is truly made in the USA has become a critical concern for industrial buyers, engineers, and contractors. Not only does country of origin impact product quality, warranty, and service, but it can also be crucial […]