Centrifugal & High Pressure Casting: Heavy‑Duty Metal Solutions

When it comes to manufacturing dense, high-strength metal components, centrifugal casting and high-pressure casting offer distinct advantages for industrial applications. These two methods are essential for producing parts with superior mechanical properties, dimensional precision, and material integrity—especially in sectors like automotive, aerospace, and heavy machinery. This guide provides a detailed comparison of both casting methods, their benefits, ideal materials, and practical applications.

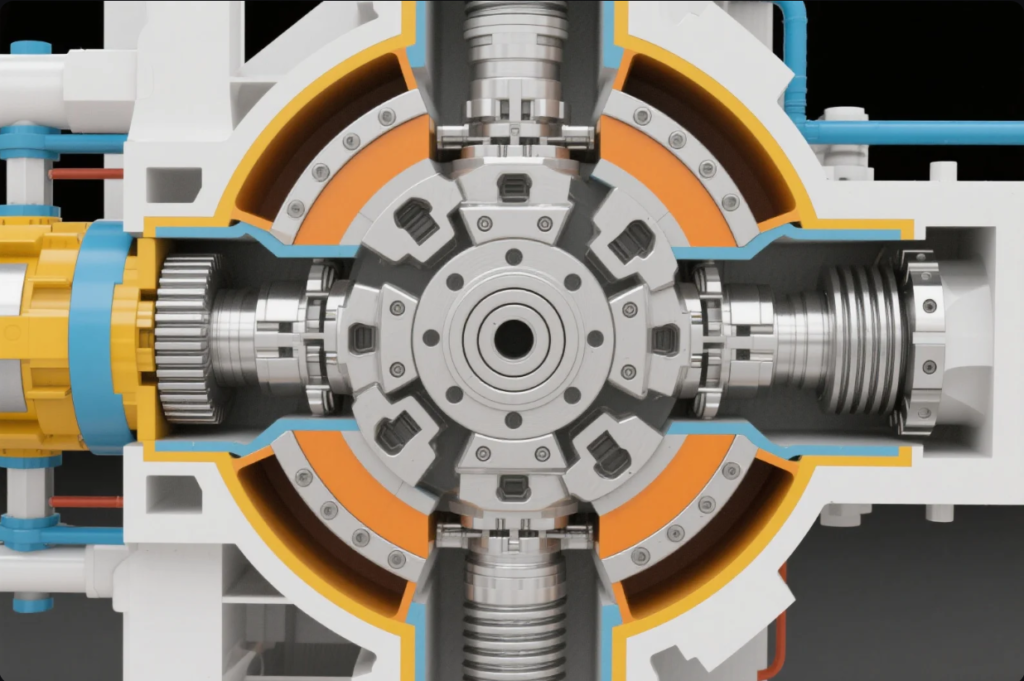

What is Centrifugal Casting?

Centrifugal casting is a process in which molten metal is poured into a rotating mold. The centrifugal force generated by the mold’s rotation pushes the metal against the mold wall, ensuring even distribution and eliminating internal voids.

🔍 Key Features:

- Produces hollow, cylindrical parts without cores

- Minimizes shrinkage, porosity, and inclusions

- Ideal for high-wear and pressure-bearing applications

- Excellent grain structure and mechanical strength

🔗 Wikipedia: Centrifugal Casting Process

How Centrifugal Casting Ensures Uniform Walls

By spinning the mold at high speed (typically 300–3000 rpm), centrifugal casting forces the molten metal outward:

- Denser metals move toward the outer wall, while impurities and lighter particles stay near the bore and are later machined off.

- This results in consistent wall thickness and dense grain structures, making the components stronger and longer-lasting.

🔗 TWI Global: Benefits of Centrifugal Casting

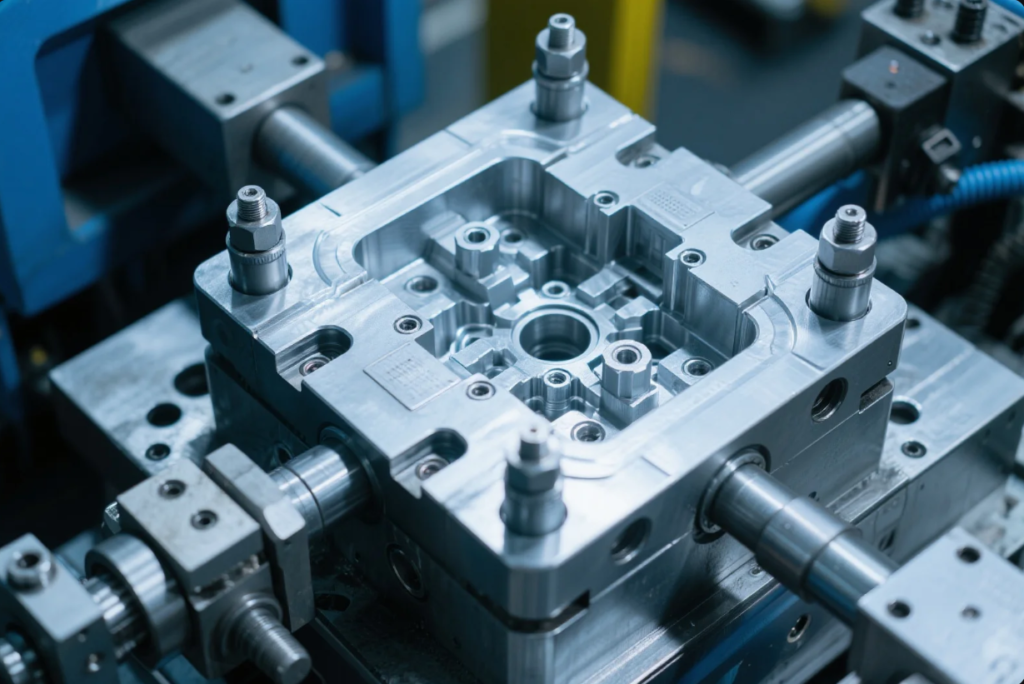

What is High Pressure Casting?

High pressure die casting (HPDC) involves injecting molten metal into a steel mold under very high pressure—typically between 1,500 and 25,000 psi—ensuring rapid filling and solidification.

🔍 Advantages:

- High precision and fine surface finishes

- Short cycle times, ideal for mass production

- Excellent for thin-walled, lightweight parts

- Can produce complex geometries with tight tolerances

🔗 NADCA: High Pressure Die Casting Guide

Benefits of High Pressure Casting for Alloy Density

High pressure casting yields low-porosity components with superior mechanical strength. Key benefits include:

- Uniform alloy distribution throughout the mold

- High cooling rates, which enhance the metal’s microstructure

- Reduced shrinkage and better dimensional control

This makes HPDC a top choice for parts that require both light weight and structural integrity, such as:

- Transmission housings

- Heat exchangers

- Engine blocks

🔗 AZoM: Microstructure in High Pressure Die Casting

Materials Best Suited for These Processes

🔧 Centrifugal Casting

- Stainless steel – heat and corrosion resistance

- Bronze & copper alloys – wear-resistant bearings and bushings

- Nickel alloys – aerospace and power generation parts

- Cast iron – large pressure pipes, rolls

🔩 High Pressure Die Casting

- Aluminum alloys – lightweight, corrosion-resistant, thermally conductive

- Magnesium alloys – lightest structural metal, excellent for electronics

- Zinc alloys – precision, strength, and castability

🔗 Matmatch: Comparison of Casting Alloys

Applications in Pipes, Automotive, and Aerospace

🛢️ Centrifugal Casting Applications

- Large industrial pressure pipes and tubes

- Hydraulic cylinders

- Jet engine components

- Furnace rollers and brake drums

🚗 High Pressure Die Casting Applications

- Automotive: Engine blocks, wheels, structural brackets

- Aerospace: Lightweight components with tight tolerances

- Consumer Electronics: Laptop housings, phone frames

- Industrial Equipment: Gear housings, enclosures, pumps

🔗 Reliance Foundry: Cast Metal Applications

FAQs

Q1: Which casting process is better for hollow pipes?

A: Centrifugal casting is ideal due to its inherent design and wall uniformity.

Q2: Can high-pressure die casting handle ferrous metals?

A: Typically no. HPDC is used for non-ferrous metals like aluminum, magnesium, and zinc.

Q3: Which process gives better mechanical strength?

A: Both are strong, but centrifugal castings are generally superior for heavy-duty applications.

Q4: What is the typical surface finish of HPDC?

A: Ra 1.6–3.2 µm, often requiring no secondary finishing.

Q5: Can you cast custom alloys?

A: Yes. We can tailor material composition based on performance requirements.

Contact Us

Looking for heavy-duty casting solutions?

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

🏭 Shandong Prime International Trade Co., Ltd. — Providing precision centrifugal and high-pressure cast parts for global industries since 1993

© 2025 PrimeCustomParts.com — Engineered Strength Through Advanced Casting