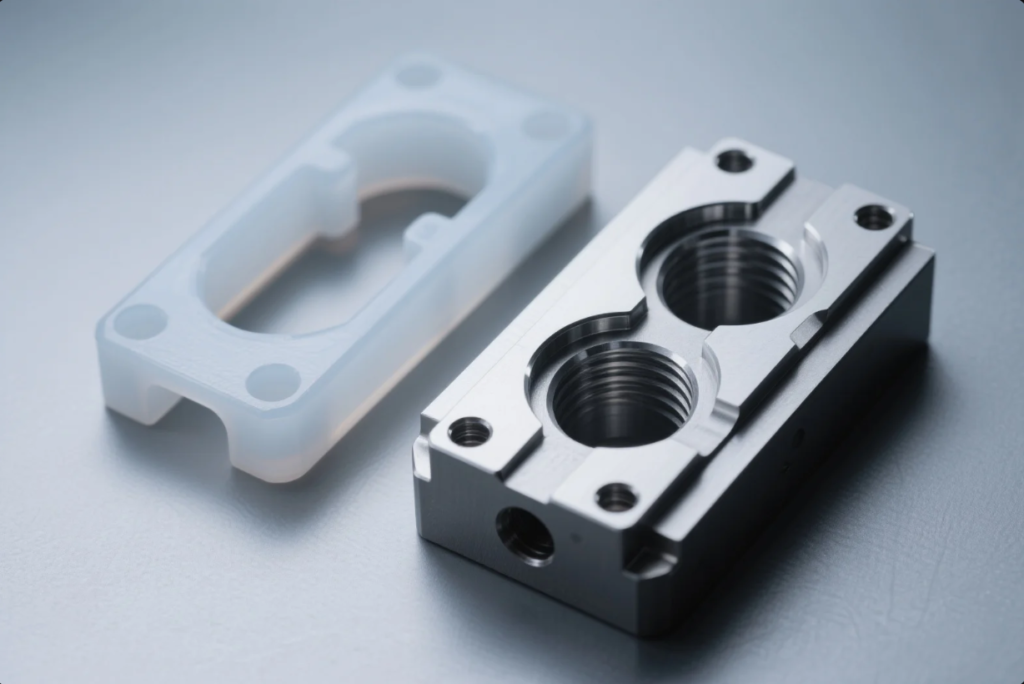

CNC Machined Plastic Parts vs Molded Parts: Which Is Right for You?

Choosing between CNC machining and injection molding is a critical decision for plastic part production. Each method offers strengths and limitations in terms of cost, lead time, precision, surface finish, and production volume. In this comprehensive guide, we’ll explore the key differences to help you make an informed choice. Plus, you’ll discover how PrimeCustomParts.com provides both services under one roof—offering maximum flexibility from prototype through full production.

Differences in Cost, Lead Time, and Minimum Order Quantity

Key factors to consider:

CNC Machining

- Setup Cost: Minimal (typically \$0–\$300 for fixtures or toolpaths)

- Lead Time: 3–7 days for the first parts

- MOQ: No minimum; perfect for single-piece or small-batch

- Cost per Part: Higher at low volume, gradually decreases

- Material Range: Broad—ABS, PC, PEEK, PVDF, etc.

- Design Iteration: Quick and cost-effective

Injection Molding

- Setup Cost: High (\$2k–\$20k+ for molds)

- Lead Time: 2–5 weeks to final samples

- MOQ: Generally 500+ parts

- Cost per Part: Very low at scale

- Material Range: Limited to moldable resins, like ABS or PEEK

- Design Iteration: Expensive — mold redesigns needed

| Metric | CNC Machining | Injection Molding |

|---|---|---|

| Setup Cost | \$0–\$300 | \$2,000–\$20,000+ molds |

| Lead Time | 3–7 days | 2–5 weeks |

| Minimum Order Quantity | 1+ | Typically 500+ |

| Cost per Part | Higher at low volume | Lower at high volume |

| Material Options | Very wide | Moldable thermoplastics only |

| Design Changes | Easy and inexpensive | Requires mold rework |

Learn more about molding costs at Protolabs and CNC workflows via Modern Machine Shop.

When CNC Machining Makes Sense for Low‑Volume Prototyping

CNC machining is ideal for:

- Early design validation – iterate without mold costs

- Low-volume production – cost-effective for under 200 pieces

- Precision prototypes – achieve ±0.02 mm or finer

- Functional testing – in final-use materials

- Complex tooling components – fine features and tight tolerances

Prime provides CNC machining using materials like ABS, Nylon (PA66), Polycarbonate (PC), Polyoxymethylene (POM), PEEK, PVDF, and more. Executors receive professionally finished samples ready for evaluation in 3–7 days.

Surface Finishes and Accuracy in CNC Plastic Components

Precision & Finish Levels

- Standard Tolerance: ±0.02 mm

- High Precision: Up to ±0.01 mm with tight control

-

Finish Options:

- Raw Machined (SPI-D1/D2) – functional prototypes

- Bead-Blasted (SPI-B2/B3) – semi-gloss exterior use

- Polished (SPI-A2) – high-gloss consumer finishes

🔗 Refer to “Surface finish” on Wikipedia for SPI definitions: Surface finish – SPI 2022 guide.

Compared to injection molding, CNC offers flexibility in finishes on a per-part basis—ideal for prototypes or low volume production where varied aesthetics are needed.

Why PrimeCustomParts.com Offers Both Solutions for Maximum Flexibility

Prime’s dual-capability model combines:

- Rapid prototyping via CNC—10–50 parts in days

- Design iterations—fast changes at low running cost

- Volume transition—mold to injection for production scale

- Ongoing CNC—custom versions, replacements, or small orders

- Simplified supply chain—one vendor covering all manufacturing stages

This integrated approach reduces risk, time, and complexity for OEMs and product development teams.

Detailed Cost & Production Timeline Comparison

| Process Phase | CNC Machining | Injection Molding |

|---|---|---|

| CAD File Submission | Accepts STEP/IGES/STL | Accepts STEP/IGES |

| DFM & Quoting | Within 24 hours | 1–2 days with mold estimate |

| Tooling Initiation | Minimal setup | Mold build (10–15 days) |

| Sample Production | Prototype in 5–7 days | T1 parts in 2–3 weeks |

| Volume Production | Continuous after prototype | After mold validation |

| Cost (Low Volume) | Higher per part, low start-up cost | Low part cost after mold investment |

| Cost (High Volume) | Scales linearly | Very low per unit |

With Prime, you get the best of both worlds—fast, accurate prototyping alongside scalable production with one trusted supplier.

FAQs: CNC Machining vs Injection Molding

Can CNC and injection molding be combined?

Absolutely—many clients prototype via CNC, then shift to molding for production.

What’s the fastest way to get prototype parts?

CNC parts are typically delivered within 3–7 business days.

How tight are CNC tolerances?

Standard is ±0.02 mm; tighter tolerances offered based on material and design.

Can CNC parts have cosmetic finishes?

Yes—available finishes include bead-blasting, polishing, and laser marking.

What’s the MOQ for molded parts?

Typically starts at 500 pieces; low-volume molds may accommodate fewer with additional cost.

How long for first molded samples (T1)?

Expect 2–3 weeks post-mold completion for T1 approval runs.

When to Use Each Process

CNC Machining Suitable For:

- Design validation and prototypes

- Fit/form/function testing

- Low-volume runs (<200 pcs)

- Custom or replacement parts

- Tight tolerance components

Injection Molding Ideal When:

- Volume > 1000 parts

- Low cost per part

- Consistent surface finish

- Features like undercuts, living hinges, inserts

Transitioning Smoothly from Prototype to Production

Prime supports a process-driven workflow:

- Deliver CNC prototypes in 3–7 days

- Gather feedback and refine design

- Approve the prototype

- Build injection molds (10–15 days)

- Produce volume run

- Provide CNC parts for future modifications or spares

This multi-step method lowers risk and improves time-to-market outcomes.

Contact Prime for Both CNC and Injection Molding Solutions

📧 [email protected]

🌐 PrimeCustomParts.com

We offer:

- Fast DFM reviews and quotes (24 hours)

- Versatile CNC and molding capabilities

- Cosmetic finishes and inserts (threaded, ultrasonic welds)

- ISO 9001 precision and full material traceability

- Global shipping with export-grade packaging

Conclusion

CNC machining provides quick, precise solutions for prototypes and low-volume runs. Injection molding delivers cost-effective production at scale with consistent quality and texture. With Prime’s in-house CNC and molding, you benefit from both worlds under one roof—optimized for speed, cost, and flexibility.

Submit your CAD files today to get a free quote for both prototyping and production manufacturing.